Understanding and Resolving Excessive Noise During Tool Grinding with Low Grinding Load

In the tool grinding industry, it’s not uncommon to encounter situations where the grinding noise is unusually loud, even when the grinding load is minimal. This phenomenon is particularly noticeable when a new grinding wheel is installed and begins its first operation on a workpiece. To understand and mitigate this issue, we’ve conducted a targeted test to investigate the root causes. Below are the test details and our analysis results.

Test Conditions

Equipment:

Grinder: Daijie S500 grinding machine

Spindle Power: 6KW

Grinding Wheel Specifications:

Type: 1A1

Size: 125X31.75X10X8 D64

Cooling Method: Oil cooling system

Workpiece Material: carbide steel rod

Workpiece Parameters:

Diameter: 16MM

Design: Four-flute

Slot Length: 60mm

Rake Angle: 15°

Helix Angle: 35°

Grinding Parameters:

Wheel Speed: 18 meters/second

Grinding Depth: 4mm

Initial Feed Rate: 200, later adjusted to 260

Results and Analysis

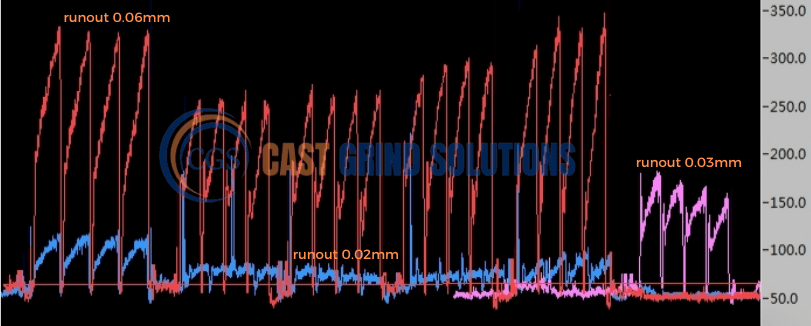

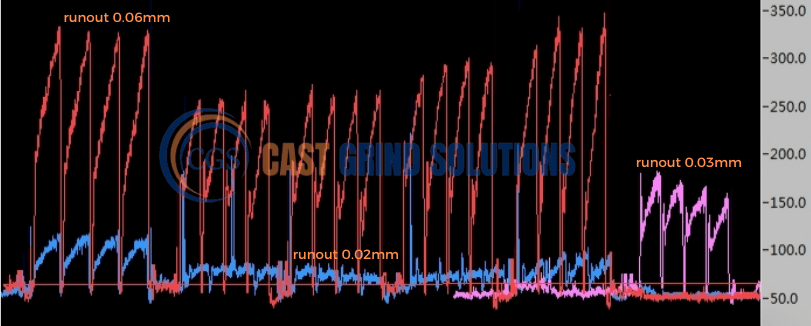

From our observations and recordings of grinding vibration amplitudes under different wheel runout values, we found that the wheel’s installation runout significantly impacts the vibration levels during grinding. Ideally, the runout of the grinding wheel should be controlled within 0.03mm to ensure that grinding vibrations remain within an acceptable range.

Potential Causes of Wheel Runout

Wheel Issues: The wheel bore may not meet standard dimensions, or the wheel might not be fully round, affecting its stable installation on the spindle.

Assembly Component Issues: The wheel arbor or spacers might not match specifications, leading to errors during assembly and affecting installation precision.

Assembly Process Contamination: During the assembly of the wheel arbor to the equipment, any foreign objects entering the assembly surface can interfere with proper installation, increasing runout.

Suggested Solutions

When faced with high vibration levels despite low grinding loads, consider the following steps:

Check the Grinding Wheel:

Verify that the wheel meets standard specifications, including bore diameter and roundness.

Assess Assembly Components:

Ensure the wheel arbor and spacers conform to specifications and verify the fitting accuracy.

Ensure Clean Assembly:

Maintain a clean assembly process to prevent foreign objects from contaminating the assembly surfaces.

By systematically checking and addressing these areas, you can effectively reduce grinding vibrations and achieve smoother, quieter grinding operations.

Conclusion

Addressing the issue of excessive noise during low-load grinding requires a thorough examination of the grinding wheel, assembly components, and assembly process cleanliness. By controlling wheel runout and ensuring precise assembly, you can significantly improve the grinding experience. Regular inspection and maintenance practices are crucial for maintaining optimal grinding conditions and achieving consistent, high-quality results.

For further assistance or specific issues encountered during the grinding process, feel free to contact our team of experts for tailored solutions and professional advice.