Determining the “best” grinding machine depends on various factors, including the specific application, material to be ground, precision requirements, and budget considerations. Different grinding machines are designed for various purposes, and each has its advantages. Here are some common types of grinding machines and their typical applications:

Surface Grinder:

Best for: Surface grinding, producing a smooth finish on flat surfaces.

Advantages: Precise and efficient for creating flat surfaces with tight tolerances.

Cylindrical Grinder:

Best for: Cylindrical grinding of external and internal surfaces.

Advantages: Suitable for producing cylindrical parts with high precision.

Centerless Grinder:

Best for: Grinding cylindrical parts without the need for a center.

Advantages: High production efficiency for continuous and consistent grinding.

Tool and Cutter Grinder:

Best for: Sharpening and reconditioning cutting tools.

Advantages: Ideal for precision grinding of various tool geometries.

Internal Grinder:

Best for: Internal grinding of bores and holes.

Advantages: Provides high precision for internal surfaces.

Bench Grinder:

Best for: General-purpose grinding, sharpening tools, and deburring.

Advantages: Compact and versatile for a variety of tasks.

Creep Feed Grinder:

Best for: Deep grinding applications with heavy stock removal.

Advantages: Efficient for removing large amounts of material in a single pass.

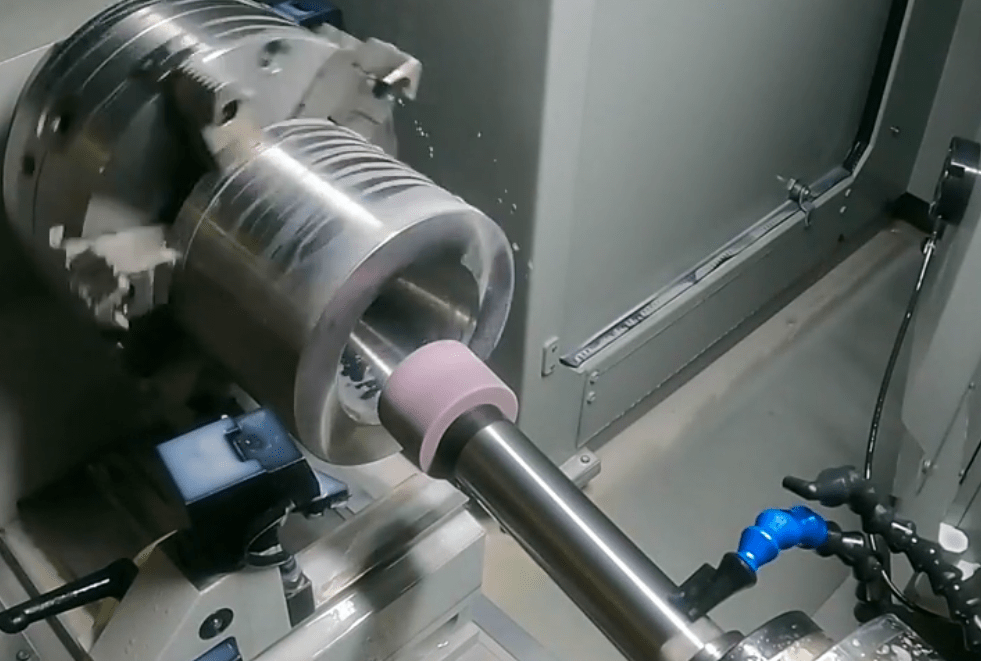

Tool Post Grinder (Lathe Attachment):

Best for: Grinding on a lathe machine.

Advantages: Convenient for in-situ grinding on a lathe.

Double Disc Grinder:

Best for: Simultaneous grinding of both sides of flat and parallel surfaces.

Advantages: High production rates for flat and parallel parts.

Blanchard Grinder:

Best for: Large parts requiring a flat and parallel surface finish.

Advantages: Efficient for grinding large workpieces with a rotary table.

Pedestal Grinder

A pedestal grinder is a type of grinding machine that is mounted on a pedestal, which is a column or stand. It is typically used for sharpening, grinding, and shaping various tools and metal objects.

CGS presents the world’s most robust high-speed metal grinder, operating at 80m/s. When equipped with brazing diamond grinding wheels, these grinders outperform their counterparts with normal bonded grinding wheels by a significant margin.

When selecting the best grinding machine, consider factors such as the type of material, required surface finish, production volume, and the level of precision needed. It’s essential to match the machine’s capabilities with the specific requirements of the task at hand. Additionally, adherence to safety guidelines and proper machine maintenance are crucial for optimal performance.