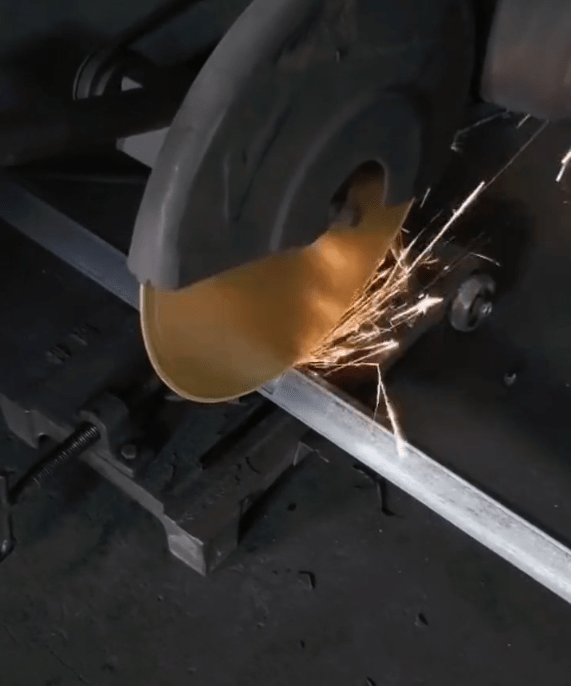

When cutting cast iron, it’s recommended to use a cutting wheel specifically designed for the material. Abrasive cutting wheels are commonly used for cutting cast iron, and among them, cutting wheels with silicon carbide or diamond abrasives are suitable choices. Here’s a brief overview:

Silicon Carbide Cutting Wheels:

These wheels are effective for cutting cast iron and other non-ferrous materials. Silicon carbide is a hard and brittle abrasive, making it suitable for applications where a sharp cut is essential. However, it may wear out faster compared to diamond abrasive wheels.

Diamond Cutting Wheels:

Diamond cutting wheels are highly effective for cutting cast iron due to the hardness and durability of diamonds. They provide a clean and precise cut, and their longevity makes them a preferred choice for cutting hard materials. Diamond cutting wheels are especially useful for cutting through cast iron pipes, bars, or complex shapes.

When selecting a cutting wheel for cast iron, consider the following:

Wheel Size: Choose a wheel size suitable for your cutting tool and the specific requirements of the job.

Abrasive Type: Silicon carbide and diamond are common abrasive types. Diamonds are harder and more durable but may be more expensive.

Thickness: Thicker wheels are generally more durable and suitable for heavy-duty cutting, while thinner wheels are better for precision cuts.

Arbor Size: Ensure the wheel’s arbor size matches the arbor size of your cutting tool.

Always follow the manufacturer’s recommendations and guidelines for the cutting wheel and cutting machine. Additionally, use appropriate safety gear, such as safety glasses and gloves, when operating cutting tools.