To cut metal, you generally need abrasive cutting wheels that are designed specifically for metal-cutting applications. The choice of wheel depends on the type of metal you’re cutting, the thickness of the metal, and the tools you have available. Here are some common types of abrasive cutting wheels for cutting metal:

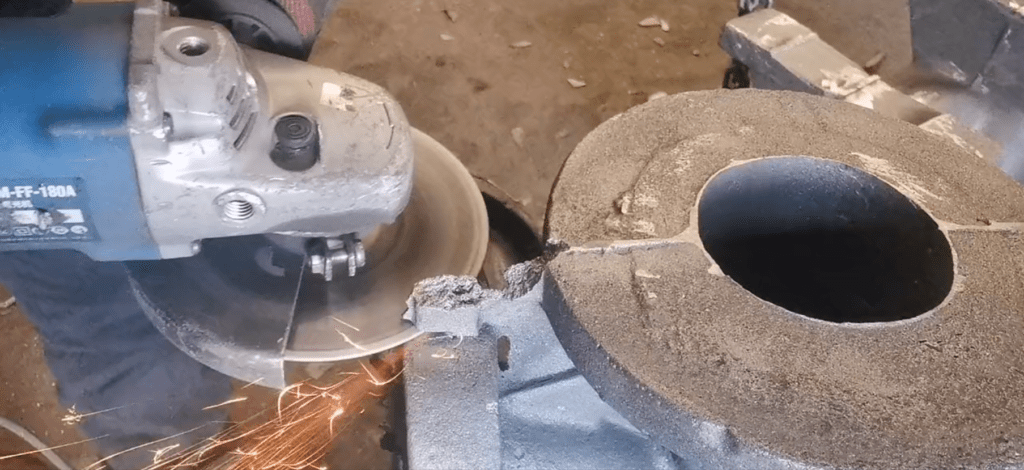

Type 1 Straight Cut-off Wheels:

These are thin, flat wheels that are used for straight-line cutting. They are commonly used with angle grinders and can be used for cutting various metals.

Type 27 Depressed Center Cut-off Wheels:

These wheels have a depressed center design that allows for flush cutting. They are suitable for cutting metal and are often used with angle grinders.

Abrasive Chop Saw Wheels:

Designed specifically for use with chop saws, these wheels are reinforced for durability and are effective for cutting metal quickly.

Metal-Cutting Carbide Blades:

Carbide-tipped blades are suitable for cutting through hard metals like steel and cast iron. They are commonly used with circular saws or miter saws.

Diamond Blades:

Diamond blades are ideal for cutting hard and abrasive metals, including reinforced concrete, as diamonds are one of the hardest materials. They are commonly used with angle grinders or specialized metal-cutting saws.

When choosing a cutting wheel for metal, consider factors such as the type of metal, the thickness of the material, the cutting tool you’ll be using, and the specific requirements of your project. Always follow the manufacturer’s recommendations and safety guidelines for the cutting wheel and cutting tool. Additionally, use appropriate personal protective equipment, such as safety glasses and gloves, when operating cutting tools.

diamond cut-off wheels vs abrasive

Diamond cut-off wheels and abrasive cut-off wheels serve different purposes and have distinct characteristics. Here’s a comparison between the two:

Diamond Cut-off Wheels:

Material: Diamond cut-off wheels are embedded with diamond particles on the cutting edge.

Hardness: Diamonds are one of the hardest materials, providing exceptional hardness and durability.

Applications:

Hard Materials: Diamond cut-off wheels are ideal for cutting hard materials such as metals, ceramics, glass, and certain composites.

Precision Cutting: They are commonly used for precision cutting where a clean and precise cut is essential.

Advantages:

Longevity: Diamond wheels tend to have a longer lifespan compared to abrasive wheels.

Clean Cut: They provide clean cuts with minimal burrs.

Disadvantages:

Cost: Diamond cut-off wheels are generally more expensive than abrasive wheels.

Abrasive Cut-off Wheels:

Material: Abrasive cut-off wheels are made from abrasive materials like aluminum oxide or silicon carbide.

Hardness: While abrasive materials are hard, they are not as hard as diamonds.

Applications:

Various Materials: Abrasive wheels are suitable for cutting a wide range of materials, including metals, plastics, and non-ferrous materials.

General Purpose: They are commonly used for general-purpose cutting.

Advantages:

Cost: Abrasive wheels are typically more cost-effective than diamond wheels.

Versatility: They can be used for cutting a variety of materials.

Disadvantages:

Wear: Abrasive wheels may wear out faster, especially when cutting hard materials.

Burrs: The cut edges may have more burrs compared to diamond-cut edges.

Choosing Between Them:

Material Type: Choose diamond cut-off wheels for cutting hard materials and when precision is crucial. Choose abrasive cut-off wheels for general-purpose cutting of various materials.

Project Requirements: Consider the specific requirements of your project, such as the need for a clean cut, cost considerations, and the type of material being cut.

Tool Compatibility: Ensure that the chosen wheel is compatible with the cutting tool you intend to use.

Both types of cut-off wheels have their advantages, and the choice depends on the specific application and project requirements.