Grinding is an indispensable process in manufacturing, shaping, and finishing various products that form the backbone of modern life. From car parts to airplane turbine blades, silicon wafers for electronics, to everyday tools like lawnmowers and axes, virtually every product owes its existence to the crucial role of grinding.

Machinery and Process:

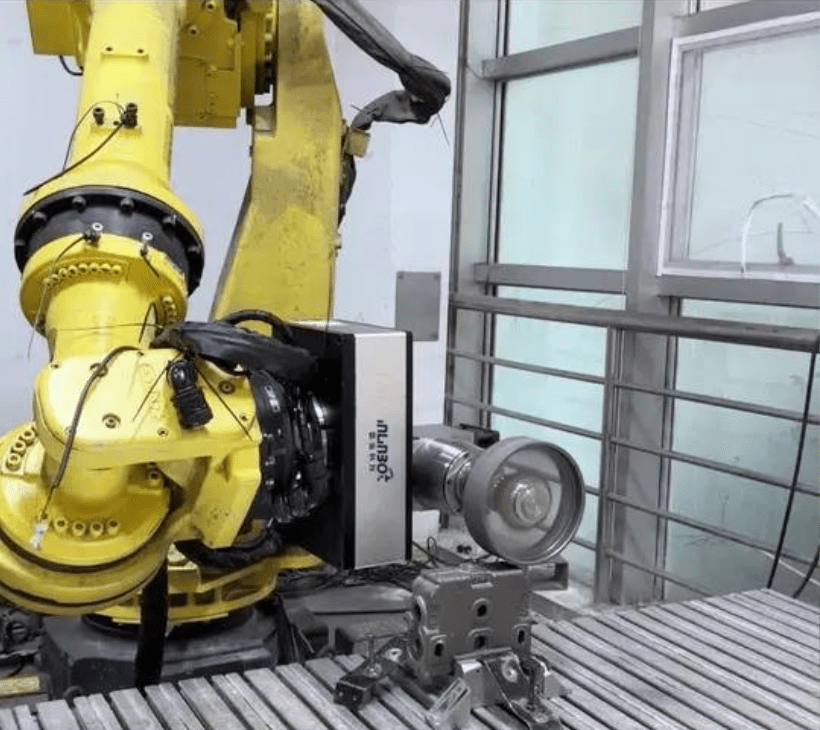

Machines employed in the grinding process are known as grinders or grinding machines. These terms are interchangeable, representing devices that utilize an abrasive product, typically a rotating wheel, to shape and finish a workpiece by removing metal and creating a surface within specified tolerances. The grinding wheel, composed of bonded abrasive grains, acts as a cutting tool, removing small chips from the workpiece.

Functions of Grinding:

Grinding serves diverse functions in manufacturing, making it indispensable for modern production. Key functions include sharpening tools, finishing surfaces, achieving close tolerances, and machining difficult materials. The process is multifaceted, contributing to the precision and quality of manufactured components.

Grinding is an abrasive machining process using a grinding wheel or grinder as a cutting tool. It is a subset of cutting, specifically in metal-cutting processes. Common in mineral processing and the cement industry, grinding imparts high surface quality and accuracy to finished workpieces, with applications ranging from fine finishing to rapid metal removal.