High-speed and low-speed grinders differ primarily in their rotation speed and applications. Here are the main distinctions:

Rotation Speed:

High-Speed Grinders: These operate at a faster rotation speed, typically measured in RPM (revolutions per minute). They are designed for tasks that require quick material removal.

Low-Speed Grinders: These operate at a slower rotation speed compared to high-speed grinders. The rotation speed is usually lower in RPM.

Applications:

High-Speed Grinders: Ideal for tasks where material needs to be removed quickly. They are often used in applications like shaping, sharpening, or removing a large volume of material in a short time.

Low-Speed Grinders: Suited for precision tasks that require more control and finesse. These are commonly used in woodworking for tasks like sharpening blades or shaping delicate materials.

Heat Generation:

High-Speed Grinders: Tend to generate more heat due to their faster rotation. This can be a consideration, especially when working with materials sensitive to heat, as excessive heat can affect the workpiece.

Low-Speed Grinders: Generate less heat during operation, making them suitable for tasks where heat could potentially damage the material.

Precision and Control:

High-Speed Grinders: May be more challenging to control, especially for tasks that require precision. They are better suited for rapid material removal rather than intricate work.

Low-Speed Grinders: Offer better control and precision, making them suitable for tasks where finesse is important.

Tool Compatibility:

High-Speed Grinders: Often compatible with a wide range of accessories, including various types of grinding wheels and cutting attachments.

Low-Speed Grinders: Typically used with specialized accessories designed for precision work.

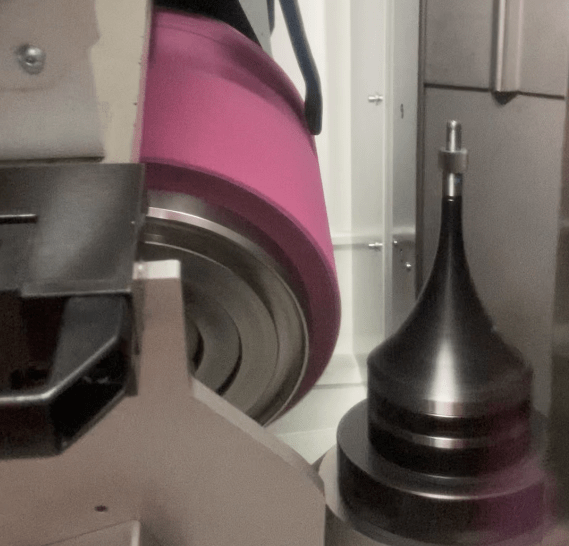

For instance, a typical pedestal grinder operates at a speed of 2900rpm, resulting in a wheel speed ranging from 30m/s to 60m/s—a standard limit for conventional bonded grinding wheels. In contrast, CGS introduces a high-speed grinder with 400mm diameter wheels that can achieve an impressive grinding speed of up to 80m/s. This elevated speed proves exceptionally advantageous for swiftly removing substantial amounts of foundry metal. To ensure efficiency and safety under such high-speed conditions, the fast pedestal grinder seamlessly integrates with brazing diamond grinding wheels, allowing for effective and secure operations at 80m/s.