A vertical grinder is a type of grinding machine where the grinding spindle is positioned vertically above the workpiece. This orientation allows for a variety of grinding operations, and vertical grinders are commonly used for tasks such as:

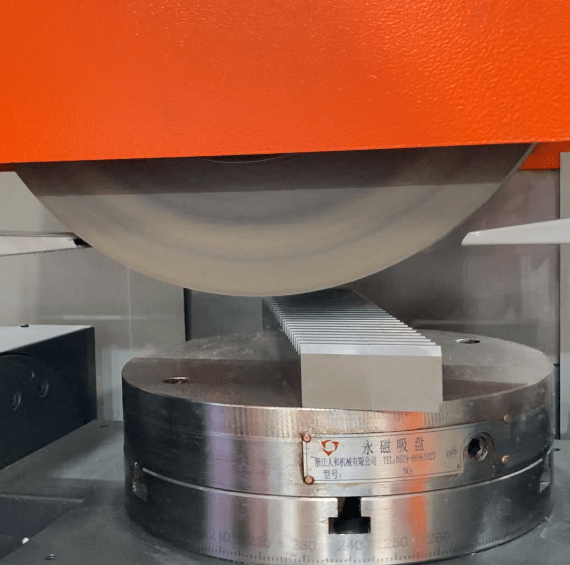

Surface Grinding:

Vertical grinders can be equipped with a grinding wheel that moves across the surface of the workpiece, removing material to achieve a flat and smooth surface.

Cylindrical Grinding:

Some vertical grinders are designed for cylindrical grinding applications, allowing for the external or internal grinding of cylindrical workpieces.

Face Grinding:

Workpieces with large flat surfaces, such as plates or blocks, can be efficiently processed using a vertical grinder equipped with a suitable grinding wheel.

Heavy Stock Removal:

Vertical grinders are often used for heavy stock removal where substantial material needs to be removed quickly. This makes them suitable for applications in industries like foundries and metal fabrication.

Precision Grinding:

In addition to heavy stock removal, vertical grinders can be adapted for precision grinding tasks where tight tolerances and fine surface finishes are required.

Tool and Die Grinding:

Vertical grinders are employed in tool and die shops for grinding and shaping tools with precision.

Multi-Surface Grinding:

Some vertical grinders offer multi-surface grinding capabilities, allowing for the processing of various surfaces on a single workpiece.

Versatile Configurations:

Vertical grinders come in different configurations, such as rotary table models or those with a reciprocating table, providing versatility in terms of the types of workpieces that can be processed.

At times, when referring to a vertical grinder, it could indicate a large, high-powered angle grinder. In such cases, a vertical grinder typically denotes an angle grinder with significant power and capabilities. This type of angle grinder is chosen for tasks requiring substantial force, particularly when dealing with large components or extensive surfaces that demand efficient material removal. The term “vertical grinder” may be used interchangeably with a powerful angle grinder designed for heavy-duty applications.

High Power Requirement:

Vertical grinders are suitable when applications demand high power to handle heavy loads or apply significant feed force. The large air motors in vertical grinders can provide substantial power, up to 4.5hp (3400 W).

Large Components and Surfaces:

Vertical grinders excel in tasks involving large components or surfaces. For instance, when working on casting deburring or fabricating extensive structures, the coverage provided by abrasives wheels of 7” (180mm) and 9” (230mm) allows for quicker material removal compared to smaller tools with 4” (100mm) or 5” (125mm) abrasive wheels. Except abrasive wheels, both angle grinder and verticle

Besides abrasive wheels, both angle grinders and vertical grinders can utilize diamond cutting wheels or diamond grinding wheels. CGS manufactures small-sized vacuum brazing diamond grinding wheels and cutting wheels for use with both angle grinders and vertical grinders.