What Is a Vitrified Diamond Wheel?

A vitrified diamond wheel is a high-performance grinding tool where diamond abrasives are bonded using a glass-ceramic (vitrified) bond. This unique bond offers superior heat resistance, porosity for coolant penetration, and exceptional grinding efficiency—making it ideal for precision machining of hard materials.

Key Technical Properties

| Parameter | Specification |

|---|---|

| Bond Type | Glass-ceramic (vitrified) |

| Porosity | 15–30% (adjustable) |

| Diamond Concentration | 25–150% (C25–C150) |

| Thermal Stability | Up to 600°C (dry), 1200°C (with coolant) |

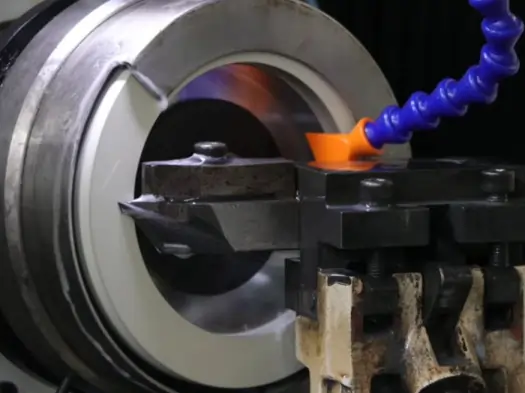

Why Choose a 6A2 Vitrified Diamond Cup Wheel?

Key Features & Benefits

✔ High Grinding Efficiency – Faster material removal than resin or metal-bonded wheels.

✔ Longer Lifespan – More durable than resin bonds, reducing frequent replacements.

✔ Superior Coolant Permeability – Prevents overheating for consistent performance.

✔ Easy Dressing – Maintains sharpness for precision grinding.

Applications

Ideal for grinding:

- Tungsten carbide PCB V-cut blades

- PCD saw blades & wood saw blades

- Spiral milling cutters & PCD turning tools

Real-World Performance

A German tool manufacturer switched to 6A2 vitrified diamond wheels for carbide V-scoring blades and achieved:

✅ 40% faster grinding speed

✅ 35% fewer wheel changes

Vitrified vs. Other Bonds: Which Is Best?

| Feature | Vitrified Diamond | Resin Bond | Metal Bond |

|---|---|---|---|

| Grinding Speed | ⭐⭐⭐⭐⭐ (Highest) | ⭐⭐⭐☆☆ | ⭐⭐⭐⭐☆ |

| Tool Life | ⭐⭐⭐⭐⭐ (Longest) | ⭐⭐☆☆☆ | ⭐⭐⭐⭐☆ |

| Surface Finish | ⭐⭐⭐⭐☆ (Smooth) | ⭐⭐⭐⭐⭐ (Smoothest) | ⭐⭐⭐☆☆ |

| Coolant Use | Excellent | Poor absorption | Moderate |

Advantages Over Resin/Metal Bonds

- Higher speed & durability than resin.

- More cost-effective & easier to dress than metal.

- Suitable for wet/dry grinding due to porous structure.

Frequently Asked Questions

❓ Can vitrified wheels be re-dressed?

→ Yes, using diamond dressers for consistent performance.

❓ Are they expensive?

→ Higher initial cost, but ROI in 3–6 months due to extended lifespan.

Ready to Upgrade Your Grinding Process?

If you need a high-efficiency 6A2 vitrified diamond cup wheel, contact us with your material specs for a customized recommendation!

Why Choose Vitrified?

✔ Best for high-volume production where wheel longevity matters.

✔ Works flawlessly with coolant or dry grinding.

✔ Longer-lasting & more efficient than resin or metal alternatives.