Description

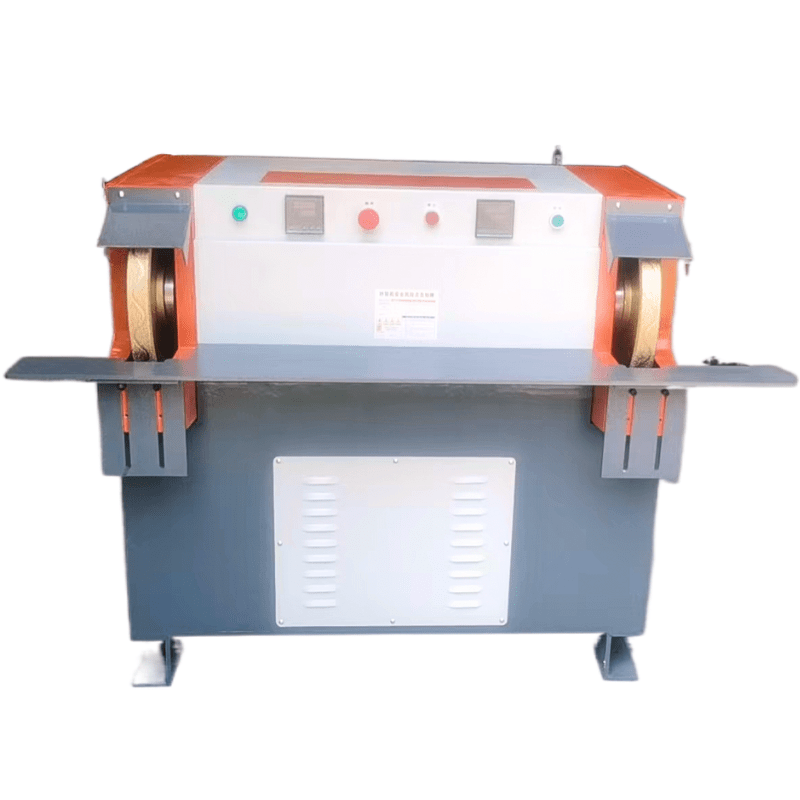

This is an alternative foundry grinder, the CWG-ST400 model has double end. Unlike the single-end version, this one features two grinding stations and a beefier motor. So it allows two workers to grind simultaneously. It’s like the standard go-to grinder in the foundry industry, perfect for handling those batch-sized casting parts.

Designed to be paired with a diamond grinding wheel, this grinder is optimized for a high-speed operation of 80m/s. The utilization of superabrasives, coupled with this remarkable speed, propels this robust grinder to outperform conventional bonded wheel grinders by a significant margin.

Technical Specifications

- Wheel Size: 400mm*40mm*100mm (16 in*1.57 in*4 in)

- Wheel Speed: single speed 80m/s; 3821rpm Standard

- Motor: 7.5kw 10HP

- Machine Size: 828*1400*1042mmMachine Weight:360KG

- Machine Weight: 500kg

- Type: double end stand

- Models: CWG-ST400

Features

- Specifically crafted for diamond grinding wheels

- Standard and robust choice for foundry factories

- Flexibility for small to mid-sized batch grinding work

- Environmentally friendly with no smoke or dust emission, ensuring worker well-being

- Adaptable work rest for enhanced versatility

- Engineered for durability in demanding environments

- Maintains a consistent fixed spindle speed

- Robust high-strength alloy steel shaft

- Maintenance-free

Application

The double-end foundry grinder is extensively utilized in various sectors and industries, offering exceptional performance in:

Foundry and Metalworking:

Ideal for foundries involved in the production of metal components, providing efficient grinding solutions for casting and metalworking processes.

Manufacturing and Production:

Widely employed in manufacturing settings where batch-sized casting parts require precise grinding operations.

Precision Engineering:

Valued in precision engineering applications, contributing to the accurate shaping and finishing of components.

Tool and Die Maintenance:

Used for tool and die maintenance, ensuring the reliable sharpening and shaping of cutting tools and dies.

Automotive Industry:

Found in the automotive sector, especially in facilities dealing with the production and maintenance of cast metal parts.

Aerospace Manufacturing:

Applied in the aerospace industry for tasks involving the grinding and shaping of components used in aircraft and spacecraft production.

Heavy Equipment Fabrication:

Employed in industries that fabricate heavy equipment, providing robust grinding capabilities for large and durable components.

General Metal Fabrication:

Used in various metal fabrication processes where a high-speed and efficient grinding machine is required.

Machining and Material Removal:

Valuable in settings where substantial material removal is needed, such as in machining and precision material shaping.

Custom Manufacturing Workshops:

Found in workshops engaged in custom manufacturing, adapting to diverse grinding requirements for different projects.