Resin Bond Diamond and CBN Wheels

Available in resin bond diamond wheel and resin bond CBN wheel

Resin Bond Features:

- High grinding efficiency

- Less heat generation then other bond types

- Good elasticity make better surface finishing

- Both dry and wet grinding

- Unmatched cut quality

- Minimize Chipping

Applications: tungsten carbide tools, ceramics, glass, ferrite, PCD, PCBN, optical glass, ruby, refractory materials, semiconductor; high-speed steel, stainless steel

Description

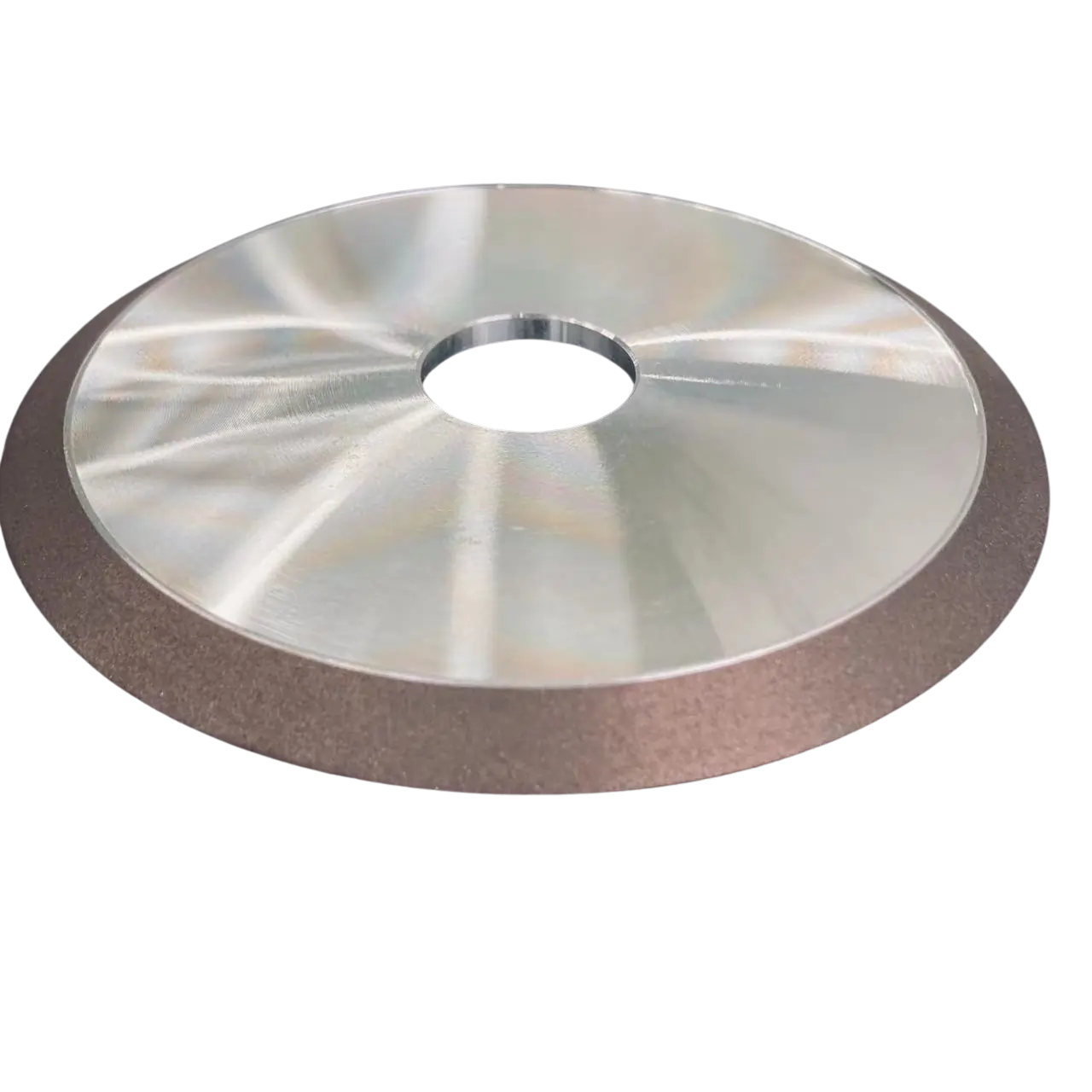

Resin Bond Diamond and CBN Wheels are grinding tools made using synthetic or natural resin as a bond, combined with the appropriate additives and diamond abrasive. This combination gives the wheels high hardness, great strength, and superior grinding capabilities, making them ideal for processing and grinding various high-hardness materials.

Key Features of Resin Bond Diamond Grinding Wheels

High Grinding Efficiency:

Diamond abrasives provide exceptional hardness and wear resistance, ensuring high-efficiency cutting performance during grinding.

Self-Sharpening:

The resin bond grips the diamond abrasives at an optimal level, allowing them to fall off easily during grinding to maintain the wheel’s sharpness.

Low Heat Generation:

These grinding wheels generate minimal heat during grinding, reducing the risk of workpiece burns and clogging.

Good Elasticity:

The resin bond imparts flexibility, enabling the wheel to adapt to the surface variations of the workpiece, improving surface roughness.

Applications:

Resin Bond Diamond Wheels are widely used for grinding high-hardness alloys, tungsten carbide tools, ceramics, glass, ferrite, PCD, PCBN, optical glass, ruby, refractory materials, and semiconductor non-metallic materials.

Key Features of Resin Bond CBN Grinding Wheels

High Hardness:

CBN abrasives, with hardness second only to diamond, maintain high-efficiency cutting performance in grinding high-hardness materials.

High Thermal Stability:

Cubic boron nitride (CBN) maintains stable cutting performance at high temperatures, making it suitable for high-speed and dry grinding.

Excellent Chemical Stability:

CBN is resistant to chemical reactions with common metals and non-metals, ensuring stability and reliability in grinding processes.

Good Elasticity:

The resin bond’s flexibility allows the wheel to adapt to the workpiece surface variations, enhancing surface roughness.

Applications:

Resin Bond CBN Wheels are mainly used for grinding ferrous metals, such as hardened steel, high-speed steel, high-vanadium high-speed steel, stainless steel, and temperature-sensitive metals.

Technical Specifications

Technical Specifications

- Abrasive Type: synthetic diamond, synthetic coated diamond, synthetic CBN, synthetic coated CBN(cubic boron nitride)

- Bond Type:resin bond ;based on your special application. Offering suitable formula

- Diamond Grit Sizes: 30 grit to 10000 grit

- CBN Grit Size: 60 grit to 5000 grit

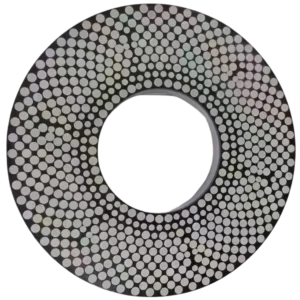

- Diamond/CBN Concentration: low , medium , high, 25%, 50%,75% 100% 125%, 150%

- Resin Bond Hardness: hard, medium, soft, super soft

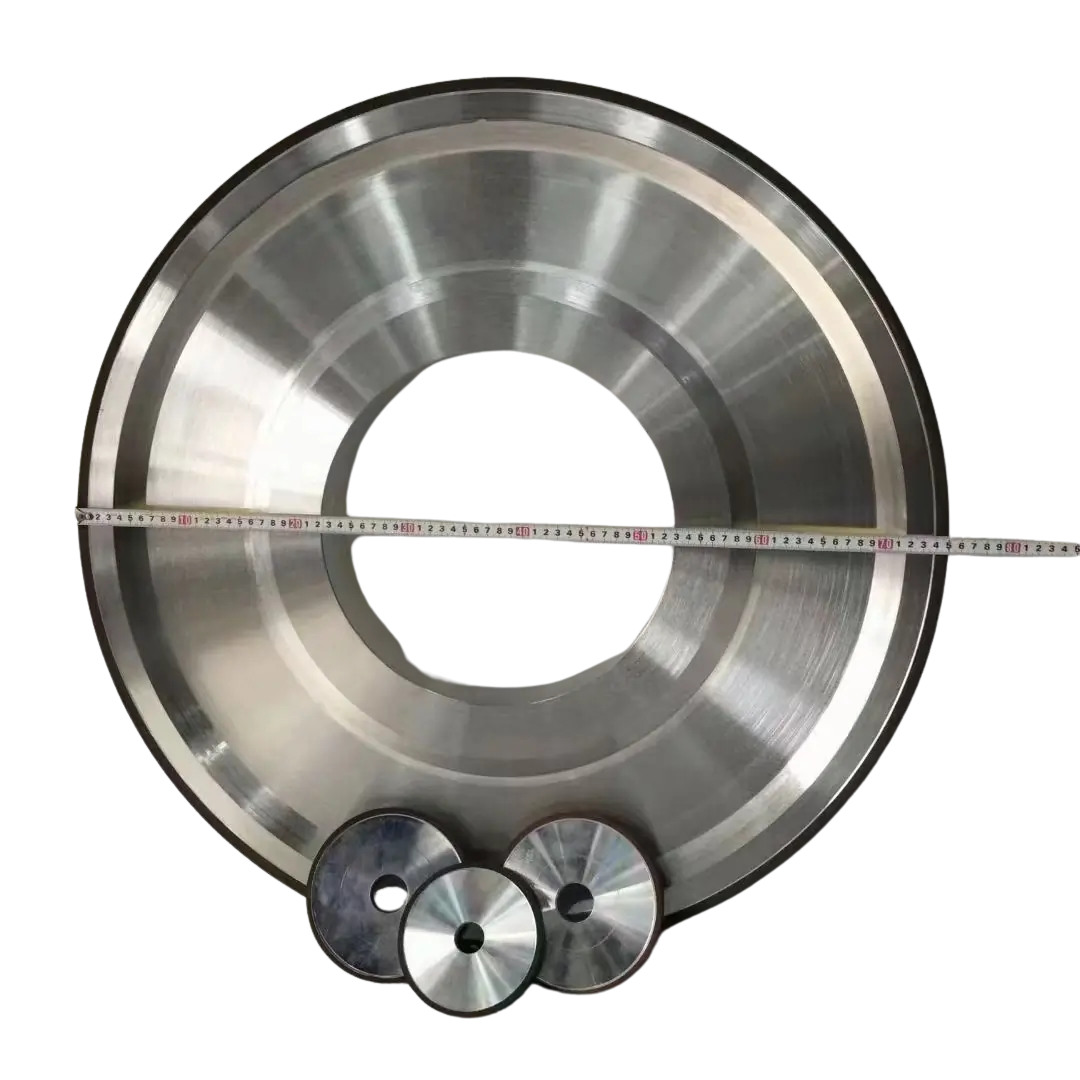

- Diameter Available : 10mm up to 800mm, for special size, we can make mould for it and meet with your specification

- Thicknesses Available : 0.03mm up to 200mm, under 1mm thickness are resin bond diamond /cbn cutting wheel

- Arbor Size(inside diameter):for any bore size, normal size are : 1/8inch, 1/4inch,3/8inch, 1/2inch, 5/8inch, 3/4inch, 1.25inch, 1.57inch, 2.75inch, 3.5inch ,3.9inch, 4.9inch, 5inch, 12inch

- Diamond Depth: any depth;such as 5mm, 10mm, 15mm, 20mm, 40mm or from OD to ID fully impregnated with diamond/CBN

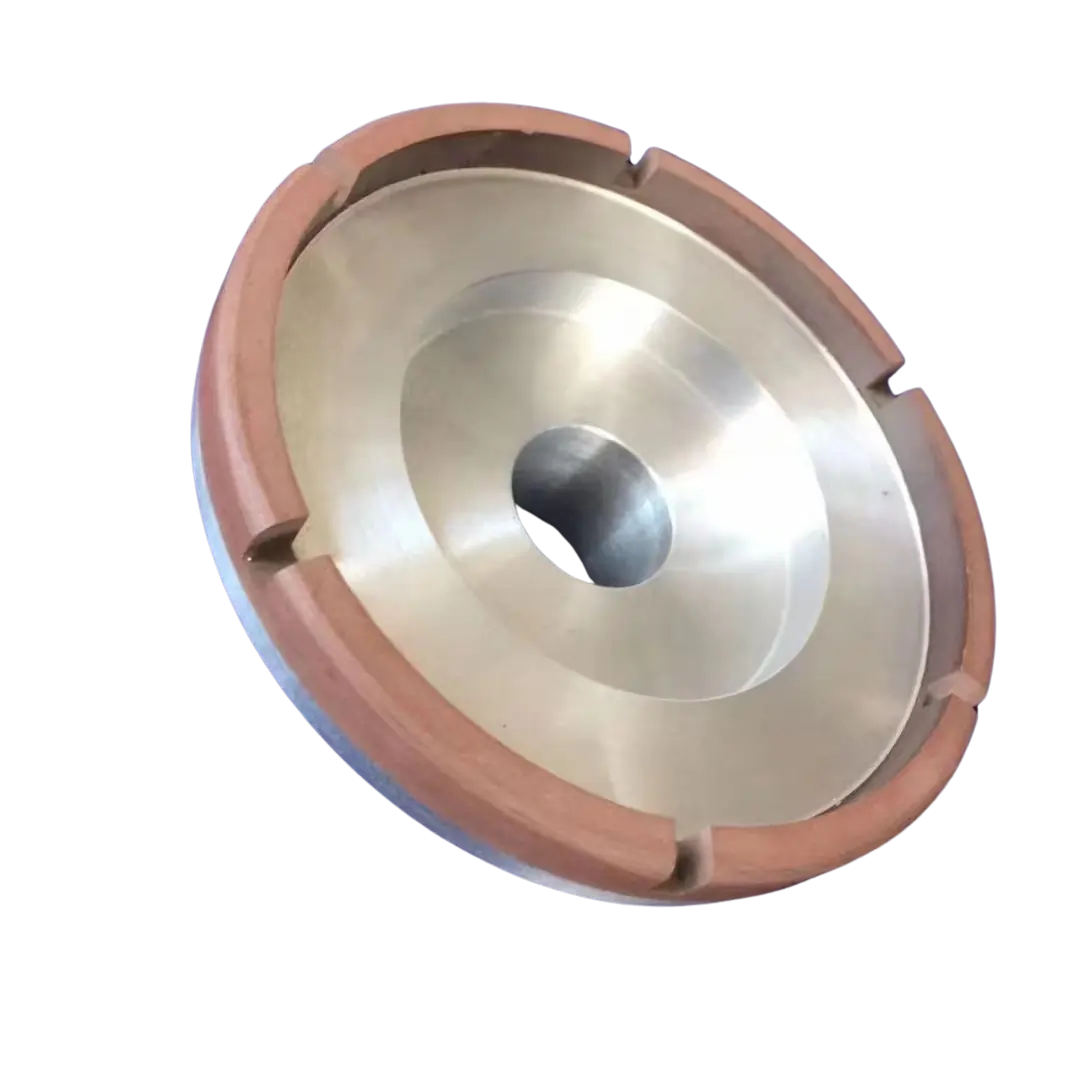

- Edge Type: continuous rim or slotted

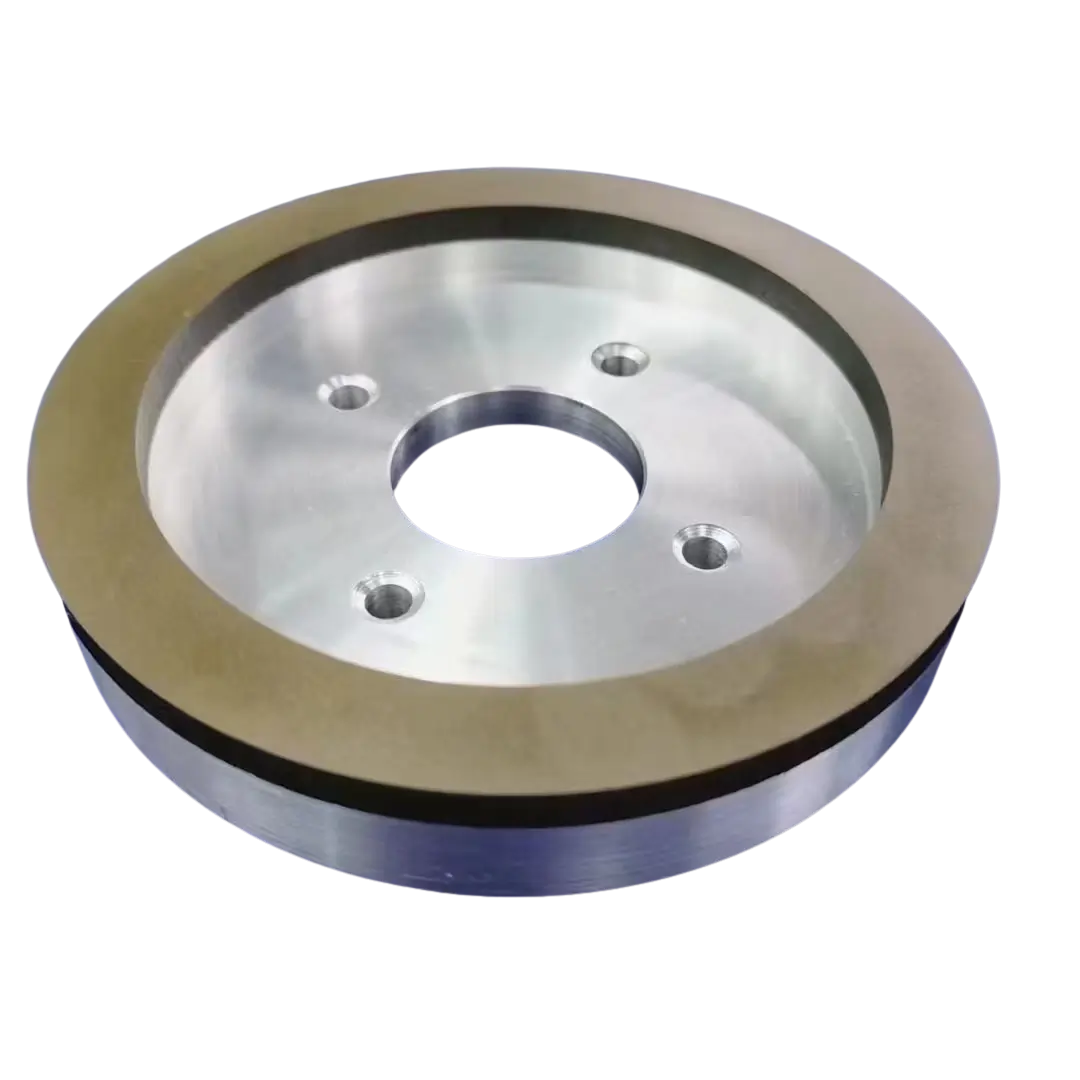

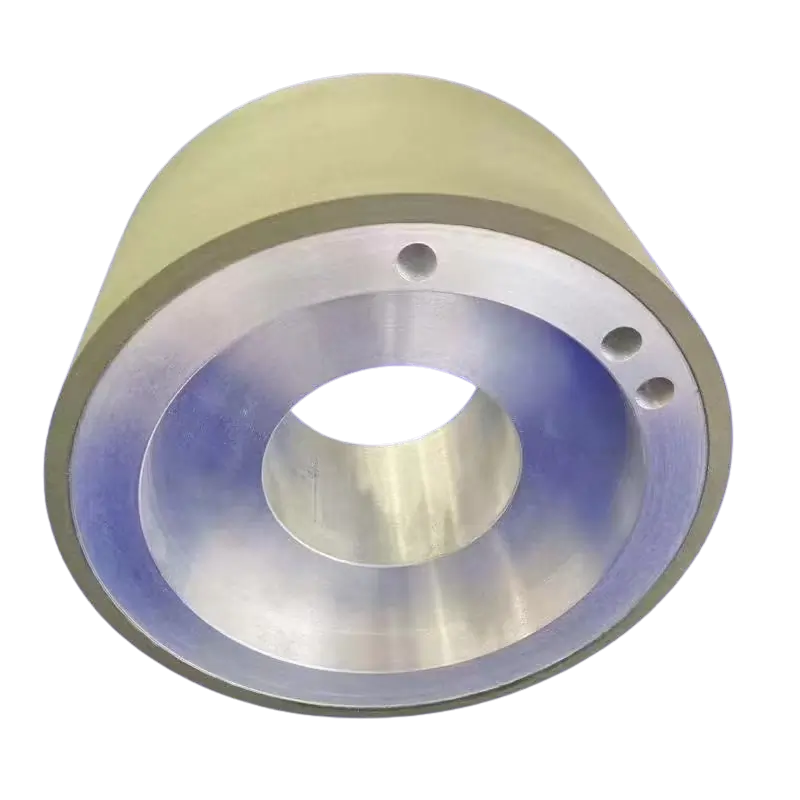

- Core Type: steel matrix, aluminum matrix, ceramic matrix, bakelite matrix

- Tolerances: based on drawing tolerance;

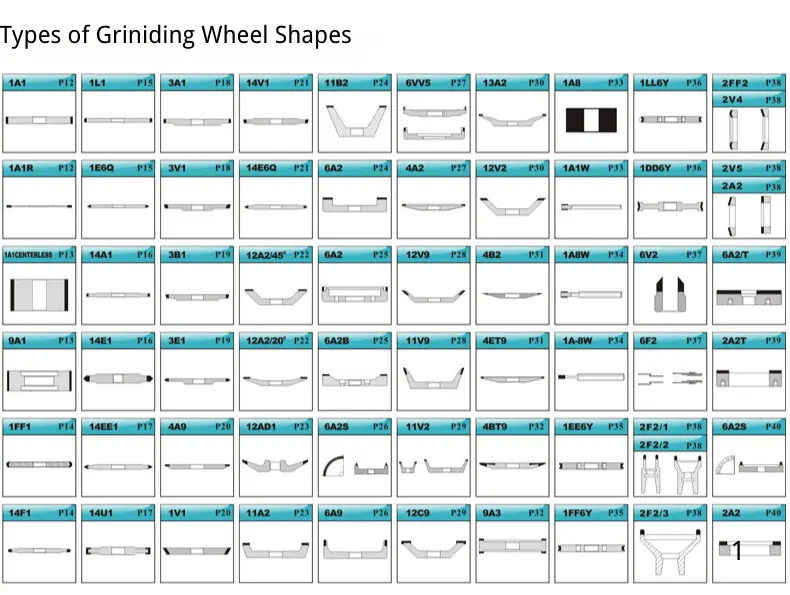

- Grinding Wheel Shapes: 1A1,1A1R, 1L1, 1V1, 3A1, 6A2, 6A9, 14V1, 13A2, 9A1, 14E1, 1FF1, 3V1, 11B2, 6VV5, 12V2, 4A2, 1E1,1M1, 1N1, 1A8, 1E8, 1zm8, 1N8, 1V8 1A1, 14U1, 6A2, 9A3, 12A2-45, 11V9, 12S2-45SS, 12V5-45, for other types, please offer drawing, we can make customized design

Features

Advantages of Resin Bond Diamond and CBN Wheels

Resin Bond CBN Wheels:

Elasticity and Self-Sharpening: Good flexibility and the ability to adjust cutting angles during grinding ensure efficient grinding and high-quality surfaces.

Cost-Effective: Suitable for small-batch, multi-variety grinding processes due to lower manufacturing costs.

Versatility: Flexible for a variety of tool shapes and sizes.

Resin Bond Diamond Wheels:

Efficient Grinding: The diamond abrasives provide efficient grinding performance, ensuring rapid completion of grinding tasks while minimizing wheel wear, thus saving costs.

Low Heat Generation and Self-Sharpening: These wheels generate minimal heat, reducing the risk of workpiece burns. Their good self-sharpening properties help maintain performance and reduce the need for frequent dressing.

Elasticity and Precision: The flexible nature of resin bonds improves surface roughness and is suitable for precision grinding, semi-precision grinding, tool grinding, and polishing, ensuring high accuracy and quality.

Short Production Cycle: Resin’s low-temperature curing characteristics allow for a shorter production cycle and simpler equipment, enabling quick market response.

Environmental and Cost Benefits: Resin bond wheels typically produce little to no dust, meeting modern industrial environmental standards. Although the initial investment is higher, their efficiency and long life result in lower overall usage costs compared to traditional materials.

Resin Types in Diamond/CBN Grinding Wheels

Phenolic Resin:

Widelyused in resin bond diamond wheels, phenolic resin boasts excellent mechanical properties, thermal stability, and chemical resistance. It firmly binds diamond abrasives, forming a robust wheel capable of withstanding the impacts and vibrations of grinding.

Polyimide Resin:

Known for its high heat resistance, mechanical strength, and storage stability, polyimide resin significantly enhances the performance of diamond wheels. With a higher hot-press temperature (235±5°C) compared to phenolic resin (185±5°C), it improves the wheel’s heat resistance, mechanical strength, and wear resistance, increasing cutting capacity and surface quality.

Extensive Formulation Library

After years of experimentation and testing, we have established a comprehensive formulation library for diamond and CBN wheels. This library contains hundreds of resin bond formulations tailored for various industry needs. These formulations address different abrasives, auxiliary fillers, resin types, molding pressures, curing cycles, and temperatures, ensuring optimal performance across a wide range of grinding applications. We also offer custom formulations based on specific requirements.

Dry Grinding vs. Wet Grinding

Resin bond diamond and CBN grinding wheels can be made for both dry and wet grinding.

Dry Grinding:

In dry grinding, resin bond diamond wheels directly engage with the material without coolant. This method is simple and does not require additional cooling and lubrication systems, suitable for applications where coolant cannot be used.

Wet Grinding:

Wet grinding employs cutting fluids to cool and lubricate during the grinding process, reducing heat accumulation and cleaning the grinding area. This method enhances grinding efficiency, surface quality, and wheel lifespan but requires extra cooling and lubrication systems, increasing equipment cost and complexity.

Whether it’s dry grinding or wet grinding, we have a wide range of formulas and successful case studies. Just clearly communicate your grinding environment and grinding requirements to us, and we can provide you with a more suitable grinding solution and the most appropriate grinding wheels.

Base Materials of Resin Bond Diamond Wheels

Resin bond diamond wheels are made using various base materials to suit specific grinding needs:

Aluminum Base: The most commonly used material, made from forged aluminum alloy, offering high strength and good plasticity for various grinding applications.

Bakelite Base: Made from 11-10 bakelite powder by hot pressing, it features a low specific gravity and good elasticity, suitable for making small-sized grinding wheels.

Other Materials: Steel matrix, ceramic matrix, phenolic resin aluminum powder bases, and phenolic resin aluminum fiber bases, each chosen based on the application and grinding conditions, providing unique benefits and limitations.

Dressing Methods for Resin Bond Diamond Wheels

Maintaining the performance of resin bond diamond wheels involves several dressing methods to ensure the wheel remains sharp and effective:

Grinding Oil Stone Method:

Using silicon carbide oil stones of various grit sizes to dress the wheels, with an abrasive protrusion of 0.01-0.02mm. This simple method requires careful control to avoid over-dressing, which can lead to abrasive breakage and uneven wheel surfaces.

WA Grinding Method:

Easily implemented on cylindrical grinders and can be adapted for surface grinders with additional power heads. The process involves shaping with a profiling dressing wheel followed by sharpening with a dresser wheel.

Dressing Block Assistance:

Using molybdenum blocks as dressing aids, the wheel is dressed by grinding the surface regularly, adjusting grinding parameters to control wheel runout within 0.003mm. The wheel is then balanced and ready for use.

Each dressing method offers advantages and should be chosen based on specific work conditions and wheel characteristics.

Application

Application and Customization

Our extensive range of resin bond diamond and CBN wheels ensures effective grinding solutions for diverse industries. Our dedicated team is ready to provide customized solutions tailored to your specific requirements, enhancing your operational efficiency and product quality.

For further inquiries or to discuss your specific grinding needs, please visit our website or contact us directly.

Applications of Resin Bond Diamond and CBN Wheels

Resin bond diamond and CBN (Cubic Boron Nitride) wheels are widely utilized across various industries due to their excellent machining performance and precision capabilities:

Precision Mechanical Processing:

Resin Bond Diamond Wheels: Esteemed for their superior processing performance and accuracy, resin bond diamond wheels are extensively used in the automotive, aerospace, and mold manufacturing industries. These wheels efficiently process high-hardness and wear-resistant materials, meeting the stringent demands of precision parts machining.

Steel and Alloy Processing:

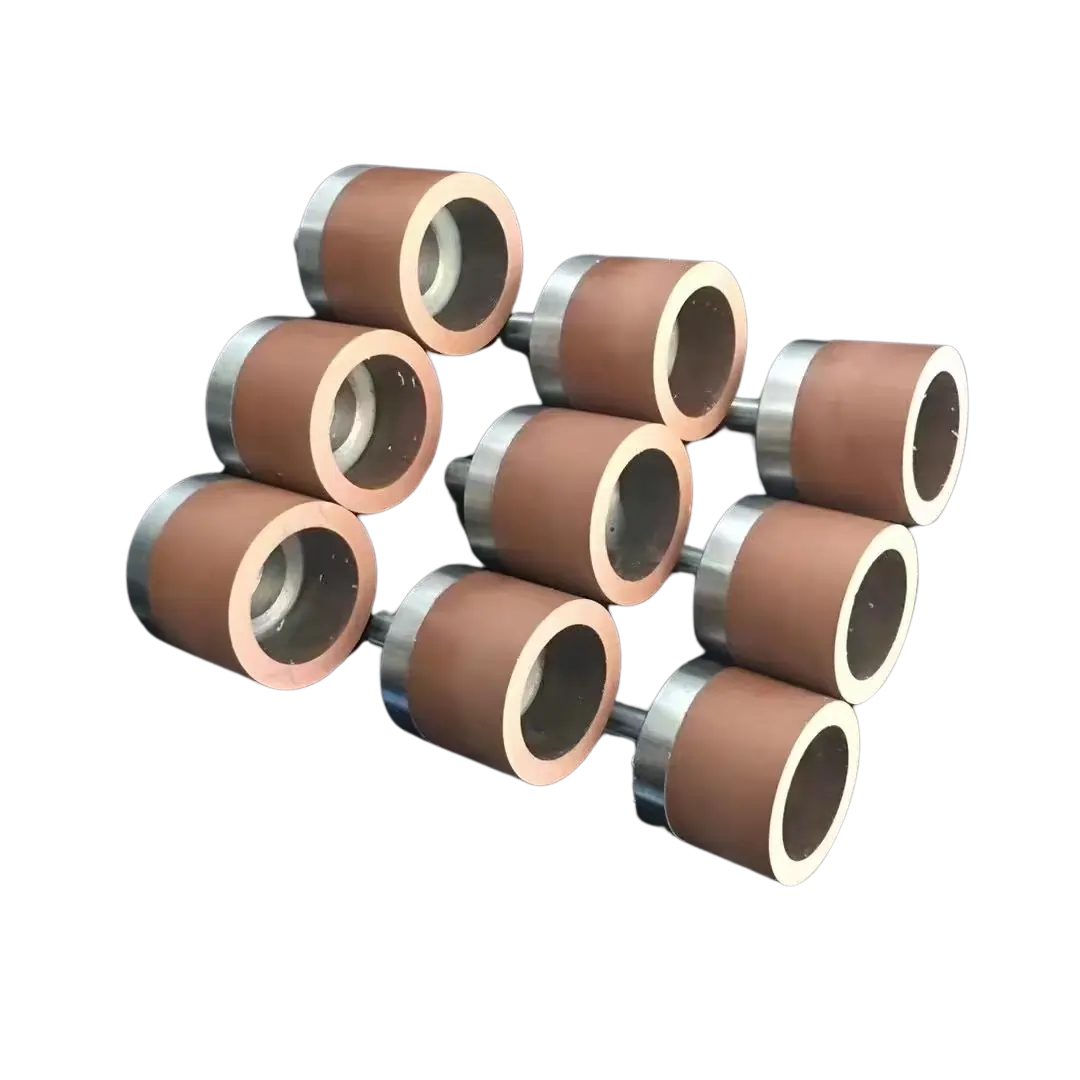

Resin Bond CBN Wheels: Primarily used for processing steel and alloys, especially high-hardness and tough materials such as hardened steel and high-speed steel. These wheels find significant applications in fields such as air conditioning compressors, automotive components, tool making industry and the bearings industry.

Plastics and Non-Ferrous Metals Processing:

Resin Bond Diamond Wheels: These wheels are also suitable for processing plastics, ceramics, glass, ruby, sapphire, semi-conductor and other non-ferrous metals due to their high-efficiency cutting capabilities.

These wheels, characterized by their high hardness and wear resistance, along with efficient machining performance, play a crucial role in modern manufacturing industries.

Specific to grinding applications, resin-bonded diamond wheels and resin-bonded CBN wheels can be utilized not limited to the following grinding methods and applications:

- Knife Sharpening

- Saw Sharpening

- Tool and Cutter Grinding

- Centerless Grinding

- OD Grinding

- ID Grinding

- Slot Grinding

- Double Disc Grinding

- Surface Grinding

- Electrochemical Grinding

Types of Diamond Grinding Wheel Shapes