Diamond Lapping Film

High-quality diamond lapping films for precision polishing and finishing

Sharp, durable and consistent

Widely used for semiconductors, optical glass, ceramics, and metals.

Diamond lapping discs and lapping sheets also available

Custom Service offered for your specific applications

Description

The diamond lapping film is a high-performance polishing tool widely used in precision manufacturing industries such as semiconductors, optical glass, ceramics, and metals. Diamond lapping films utilize electrostatic field technology to uniformly distribute fine diamond abrasives on a high-strength film substrate, ensuring excellent grinding and polishing performance. This technology allows the abrasives to adhere firmly to the substrate while maintaining sharpness and grinding efficiency.

Composition of Diamond Lapping Film

1, Abrasives of Lapping Film

Material: Composed of diamond particles, with sizes ranging from a few micrometers to tens of micrometers. These particles are evenly distributed using electrostatic planting technology.

Types of Abrasives: Electrostatic polishing belts primarily use three types of abrasives:

- Aluminum Oxide (Al₂O₃): Suitable for general-purpose grinding.

- Silicon Carbide (SiC): Ideal for hard and brittle materials.

- Diamond: The hardest abrasive, used for ultra-precision polishing of high-hardness materials.

Diamond Abrasives: Synthetic diamond micropowder is a new type of super-hard abrasive, widely used in manufacturing tools for processing high-hardness and high-precision items. It is particularly effective for grinding and polishing hard materials such as tungsten carbide, gemstones, ceramics, and optical glass.

2, Substrateof Diamond Microfinishing Film

Material: PET (Polyethylene Terephthalate) polyester film is commonly used as the base material for diamond lapping polishing film.

Advantages:

- Smooth Surface: Ensures uniform distribution of abrasives, reducing the risk of scratching the workpiece.

- High Tensile Strength: Provides excellent mechanical strength and durability.

- Heat and Water Resistance: Suitable for both dry and wet grinding applications.

- Dimensional Stability: Resists deformation under varying conditions.

3, Bonding Agentof Diamond Lapping Microfinishing Film

Material: Typically epoxy resin or polyurethane, chosen for their high adhesive strength and heat resistance.

Function: Ensures the diamond particles are firmly fixed to the substrate, maintaining consistent grinding performance.

Advantages of Diamond Lapping Film

1,Electrostatic Planting Technology:

The diamond abrasives are attached using electrostatic field forces, ensuring that the particles are oriented with their sharp edges outward. This results in:

- High Grinding Efficiency: Sharp edges provide superior cutting performance.

- Uniform Particle Distribution: Reduces the risk of scratching and ensures consistent surface finish.

- Durability: The diamond abrasives are firmly bonded, extending the diamond lapping belt’s lifespan.

2,Consistent Performance:

From the first workpiece to the last, the lapping film belt delivers consistent results, ensuring high precision and repeatability.

3, Versatility:

Suitable for both dry and wet grinding, making it adaptable to various industrial applications.

4,High Efficiency:

Thinner and longer diamond microfinishing film roll reduce the frequency of replacements, improving productivity.

5,Surface Quality:

The uniform distribution of diamond abrasives and the high-strength substrate ensure a smooth, scratch-free finish.

Application Characteristics of Diamond Lapping Film

1,Sharp Abrasives:

Diamond particles have exceptional hardness and sharp cutting edges, enabling efficient grinding and polishing.

2,High-Strength Film Substrate:

The robust substrate provides excellent tensile strength and surface flatness, capable of withstanding high grinding pressures.

3,Scratch Resistance:

The concentrated diamond particle size distribution minimizes the risk of scratching the workpiece.

4,Wide Range of Applications:

Suitable for precision polishing in industries such as semiconductors, optics, ceramics, and metals.

Technical Specifications

Technical Parameters of Diamond Lapping Film

| Parameter | Details |

| Grit Size Range | 1-50 microns (coarse: 20-50, medium: 10-20, fine: 1-10) |

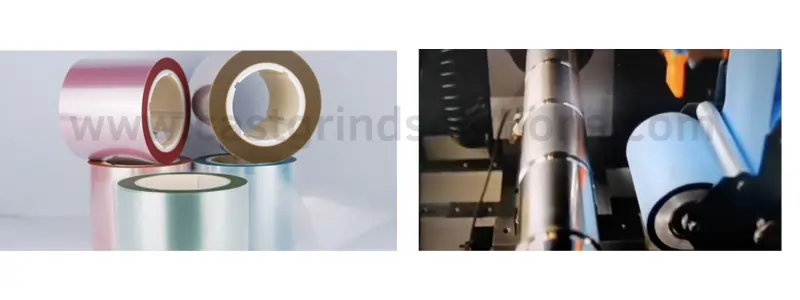

| Color Coding | Green (coarse), Blue (medium), Red (fine), Yellow (ultra-fine) |

| Substrate Thickness | 50-200 microns (50-100 for precision, 100-200 for durability) |

| Bonding Agent | Epoxy resin (high strength) or polyurethane (flexibility) |

| Film Dimensions | Width: 10-100 mm, Length: 1-10 meters |

| Polishing Parameters | Pressure: 10-100 N, Speed: 100-1000 RPM, Cooling: Dry or Wet |

Below are detailed introduction of above technical parameters .

1, Diamond Grit Size Range of Diamond Mirofinishing Film

The grit size of diamond abrasives in lapping films typically ranges from a few micrometers to tens of micrometers. The choice of grit size depends on the desired surface finish and the material being polished. Common grit size ranges include:

Coarse Grit: 20-50 microns

- Used for rough polishing and rapid material removal.

- Ideal for initial grinding and shaping of hard materials like ceramics, tungsten carbide, and hardened metals.

Medium Grit: 10-20 microns

- Used for intermediate polishing to achieve a smoother surface finish.

- Suitable for preparing surfaces for final polishing.

Fine Grit: 1-10 microns

- Used for precision polishing and mirror finishing.

- Ideal for achieving ultra-smooth surfaces on materials like optical glass, semiconductors, and precision components.

2, Diamond Lapping Film Color Coding and Grit Size Relationship

The color of diamond microfinishing film belts often corresponds to the grit size, making it easier to identify the appropriate lapping film for specific applications. The common color-coding system is as follows:

Green: Represents coarse grit (20-50 microns).

- Used for heavy material removal and rough polishing.

Blue: Represents medium grit (10-20 microns).

- Used for intermediate polishing and surface preparation.

Red: Represents fine grit (5-10 microns).

- Used for high-precision polishing and achieving smooth finishes.

White: Represents ultra-fine grit (1-5 microns).

- Used for mirror finishing and ultra-precise polishing of delicate materials.

3, Diamond Lapping Film Substrate Thickness

The substrate of diamond lapping microfinishing film is typically made of PET (Polyethylene Terephthalate) or polyimide film, with thicknesses ranging from 50 to 200 microns. The choice of thickness depends on the application:

50-100 microns:

- Suitable for high-precision polishing and complex curved surfaces.

- Provides flexibility and conformability to intricate shapes.

100-200 microns:

- Suitable for rough polishing and applications requiring higher durability.

- Offers better resistance to high pressures and mechanical stress.

4. Diamond Lapping Film Dimensions

Diamond polishing film are available in various widths and lengths to suit different applications. Common dimensions include:

Width: 10-100 mm

- Narrow lapping film rolls are used for small or intricate components, while wider belts are suitable for larger surfaces.

Length: 1-10 meters

- Longer lapping film rolls are used for continuous polishing operations, reducing the frequency of lapping film changes.

Diamond lapping films can be also made into lapping film discs and lapping film sheets. Shapes and size can be customized production.

5. Polishing Parametersof Diamond Mirofinishing Films

The performance of diamond lapping films depends on several operational parameters, including:

Polishing Pressure: 10-100 Newtons

- Higher pressure is used for coarse polishing, while lower pressure is applied for fine finishing.

Rotational Speed: 100-1000 RPM

- Higher speeds are used for rapid material removal, while lower speeds are preferred for precision polishing.

Cooling Method: Dry or Wet Polishing

- Dry Polishing: Suitable for materials that do not generate excessive heat.

- Wet Polishing: Uses coolant to reduce heat and prevent damage to the workpiece or belt.

6. Diamond Lapping Film Applications Based on Grit Size

Coarse Grit (20-50 microns):

- Metal rollers, rough grinding of ceramics, and initial shaping of hard materials.

Medium Grit (10-20 microns):

- Automotive crankshafts, camshafts, and intermediate polishing of optical components.

Fine Grit (1-10 microns):

- Semiconductor wafers, optical lenses, and precision components requiring mirror finishes.

Features

At Cast Grind Solutions, we specialize in providing high-quality diamond lapping films designed to meet the most demanding precision grinding and polishing requirements. Our products are trusted by industries such as semiconductors, optics, ceramics, and metals for their exceptional performance and reliability. Whether you need standard products or customized solutions, we are here to help.

Our Diamond Lapping Microfinishing Film Features

1,Premium Quality:

- Our diamond lapping films are manufactured using high-grade synthetic diamond abrasives, ensuring superior hardness, sharpness, and durability.

- The lapping films deliver consistent performance, enabling precise material removal and ultra-smooth surface finishes.

2,Wide Range of Grit Sizes:

- We offer diamond lapping films in a comprehensive range of grit sizes, from coarse to ultra-fine, to suit various applications:

3,Customizable Sizes and Shapes:

We understand that every application is unique. That’s why we provide customized diamond lapping films tailored to your specific requirements.

Customization options include:

- Size: Lapping films can be cut to your desired dimensions (e.g., sheets, discs, or rolls).

- Shape: Custom shapes to fit specialized tools or equipment.

Our Services

1,Expert Product Recommendations:

If you’re unsure about the best grit size, lapping film parameters, or configuration for your application, our team of experts is here to assist you.

We will analyze your specific needs and recommend the optimal diamond lapping film and grinding solution to achieve your desired results.

2,Technical Support:

Our team provides comprehensive technical support, including guidance on:

- Selecting the right grit size for your material and finish requirements.

- Optimizing polishing parameters (e.g., pressure, speed, cooling methods).

- Troubleshooting and improving your grinding processes.

3,Custom Solutions:

We work closely with you to develop customized diamond lapping films that meet your exact specifications.

Whether you need unique sizes, shapes, or specialized backing materials, we can deliver.

Why Choose Cast Grind Solutions?

1,Unmatched Quality:

Our diamond lapping films are engineered to deliver consistent performance and long-lasting durability, reducing downtime and costs.

2,Industry Expertise:

With years of experience in precision grinding and polishing, we understand the challenges of various industries and provide solutions that work.

3,Customer-Centric Approach:

We prioritize your needs and offer personalized service to ensure you get the best possible product for your application.

4,Global Reach:

We serve customers worldwide, providing reliable products and services to meet global standards.

Application

Applications of Diamond Lapping Film

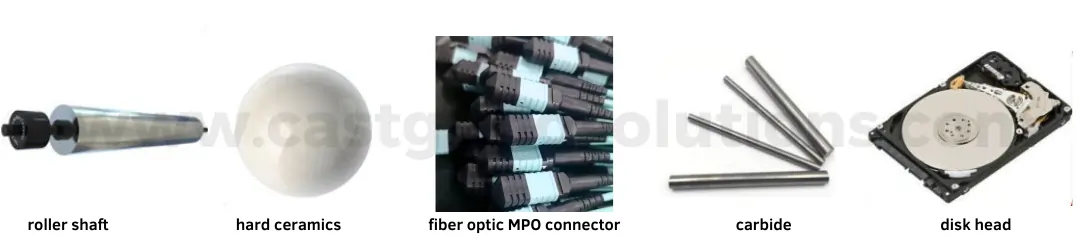

- Metal Rollers

Diamond polishing film is widely used for fine grinding and mirror polishing of metal rollers, enhancing surface smoothness and precision.

- Automotive Industry

Crankshafts and Camshafts: Critical engine components requiring high precision. Diamond finish film ensure:

Improved wear resistance.

Enhanced surface finish and dimensional accuracy.

Traditional cloth-backed finishing film often shrink or deform in water-based cooling systems, whereas film-backed diamond micro-finishing film maintains stability and performance.

- Semiconductors

Precision polishing of silicon wafers and sapphire substrates.

- Optical Glass

Polishing of lenses, prisms, and other optical components to achieve high clarity and precision.

- Ceramics

Grinding and polishing of structural ceramics and functional ceramics.

- Other Precision Applications

Polishing of fiber optic connectors, magnetic disks, and other high-precision components.

The diamond lapping film is an indispensable tool in modern precision manufacturing. Its unique combination of high hardness, uniform particle distribution, and durability makes it ideal for applications requiring ultra-smooth surfaces and high accuracy. As technology advances, these lapping film will continue to play a vital role in achieving superior surface finishes across various industries.

If you’re looking for high-quality diamond lapping films or need assistance in selecting the right product for your application, Cast Grind Solutions is here to help. Our team of experts is ready to provide personalized recommendations and customized solutions to meet your unique needs.