Description

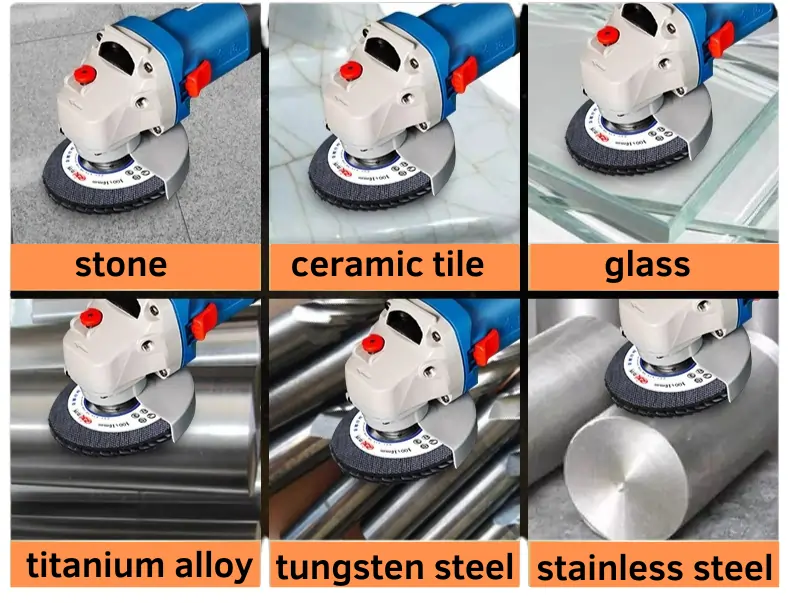

Diamond flap discs replace traditional zirconia and aluminum oxide flap disc with electroplated diamond flap disc, significantly enhancing sharpness and durability. They are compatible with all angle grinders and handheld electric grinding machines. Diamond flap wheels are ideal for grinding, chamfering, and polishing hard and brittle wear-resistant materials, such as:

- Thermal spray coatings

- Tungsten carbide with complex 3D shapes

- Monocrystalline and polycrystalline silicon

- Ceramics, glass, quartz, stone and slabs

- Fiberglass and carbon fiber composites

Key Features & Advantages of Diamond Flap Wheel

High Grinding Efficiency – Diamond flap sanding disc offers superior sharpness, enabling rapid material removal and increasing productivity.

Extended Service Life – Diamond’s extreme hardness ensures an ultra-long lifespan, making these diamond flapper discs significantly more durable than traditional abrasives.

Uniform Grinding Performance – Maintains consistent grinding pressure, delivering smooth, even surface finishes with minimal operator fatigue.

Wide Application Range – Suitable for a variety of hard, brittle, and wear-resistant materials, making it a versatile grinding tool for different industries.

Comfortable Operation – Reduces vibration compared to cup wheels, improving user comfort and lowering operator fatigue.

Technical Specifications

Technical Specifications of Diamond Flap Wheel Disc

Abrasive Type: High-quality diamond abrasive, tightly bonded to prevent grain loss

Manufacturing Process: Electroplated diamond technology for enhanced adhesion and longevity

Diamond Flap Wheel Base Materials: Available in plastic, fiberglass mesh, or aluminum backing plates (customizable)

Outer Diameter Options: 100mm (4”), 115mm (4.5”), 125mm (5”)

Bore Size: 16mm, 22.23mm

Grit Sizes Available: 60#, 80#, 120#, 180#, 200#, 400#, 600#

Maximum RPM: 12,000 RPM

Recommended Working Speed: 8,000 RPM

QTY of Flaps: 46 Flaps, 56 Flaps, 72 Flaps(customizable upon request)

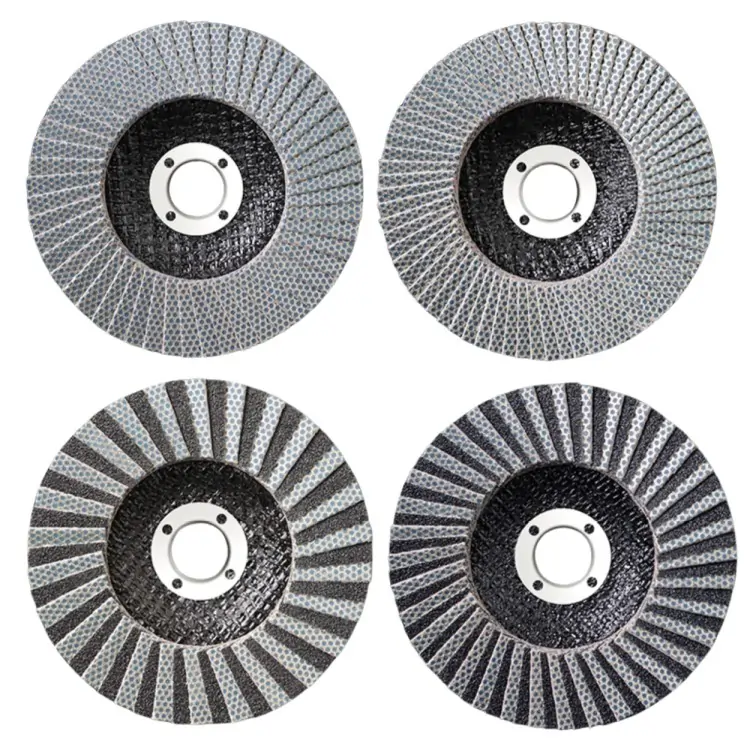

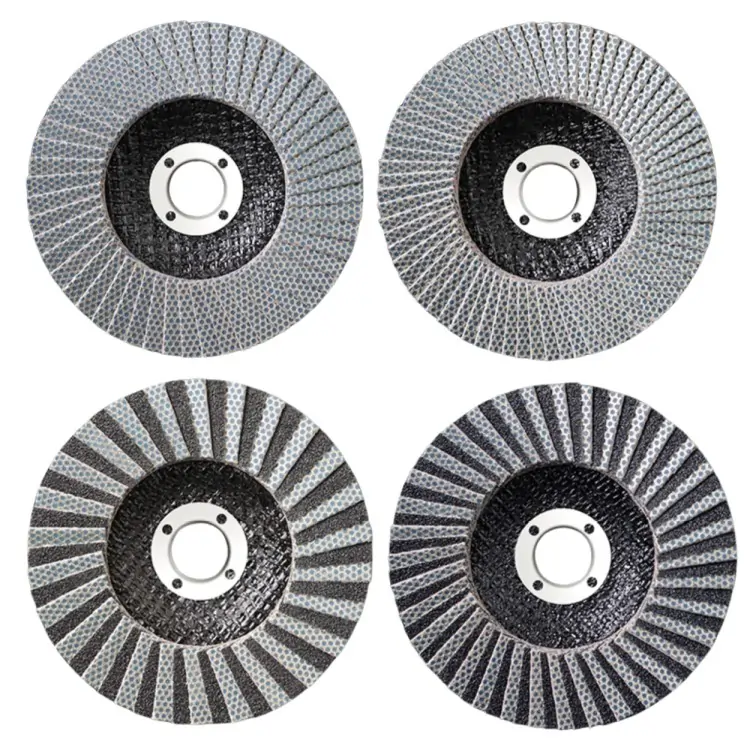

Types of Diamond Grinding Flap Wheel

Fully Electroplated Diamond Flap Cup Discs – Every flap consists of diamond-coated abrasive, delivering maximum durability and grinding efficiency.

Hybrid Diamond & Silicon Carbide Flap Discs – Alternates between diamond-coated and silicon carbide abrasive flaps. A cost-effective option that balances affordability with durability while maintaining high grinding efficiency.

Normal Diamond Flap Wheel Size

| Diameter(inch, mm) | Bore Size(inch, mm) | Number of Flaps | Grit Size(um) |

| 4” (100mm) | 16mm | 23 diamond Flaps+23 Silicon carbide Flaps | 60#,80#, 120#,180#,200#,400#;600#

|

| 4” (100mm) | 16mm | 28 diamond Flaps+28 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600#

|

| 4” (100mm) | 16mm | 36 diamond Flaps+36 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600#

|

| 4.5” (115mm) | 22.23mm | 23 diamond Flaps+23 Silicon carbide Flaps | 60#,80#, 120#,180#,200#,400#;600# |

| 4.5” (115mm) | 22.23mm | 28 diamond Flaps+28 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600# |

| 4.5” (115mm) | 22.23mm | 36 diamond Flaps+36 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600# |

| 5” (125mm) | 22.23mm | 23 diamond Flaps+23 Silicon carbide Flaps | 60#,80#, 120#,180#,200#,400#;600# |

| 5” (125mm) | 22.23mm | 28 diamond Flaps+28 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600# |

| 5” (125mm) | 22.23mm | 36 diamond Flaps+36 SIC Flaps | 60#,80#, 120#,180#,200#,400#;600# |

Features

Why Choose Cast Grind Solutions Diamond Flap Wheel?

Premium Diamond Abrasive – Utilizes high-quality diamond particles for long-lasting performance and superior cutting ability.

Electroplated Technology – Ensures diamond grit remains securely bonded to the flaps, preventing premature grain shedding and maximizing flap disc lifespan.

Multi-Purpose Grinding – Perfect for construction materials, including stone, ceramics, glass, stainless steel, and hard alloys.

Optimized Pressure Distribution – The flap wheel design evenly distributes grinding pressure, reducing material loading and improving work efficiency.

Enhanced Stability & Safety – Manufactured with precision to ensure safe and reliable operation under high-speed conditions.

Application

Applications of Diamond Flap Wheel Disc

Grinding & Polishing – Ideal for achieving smooth finishes on ceramics, glass, and stone.

Deburring – Effectively removes burrs from metal, composites, and hard coatings.

Edge Chamfering – Perfect for beveling edges of glass, quartz, and engineered stone.

Surface Preparation – Prepares surfaces for bonding, painting, or finishing applications.

For high-performance, long-lasting grinding solutions, Cast Grind Solutions’ diamond flap wheel disc offers the ultimate combination of efficiency, durability, and precision. Contact us today to find the perfect diamond flap disc for your application!