Diamond Cutting Discs for Cast Parts

- Available in a range of outer diameters: 4.5 inches, 5 inches, 7 inches, 12 inches, and 14 inches.

- Multiple inner bore sizes, including 5/8 inch, 7/8 inch, 1 inch, with customization options.

- Diamond grit sizes: D601, 30#, D561, 40# for super sharp cutting.

- Ideal for cutting castings of various sizes in the foundry industry.

Description

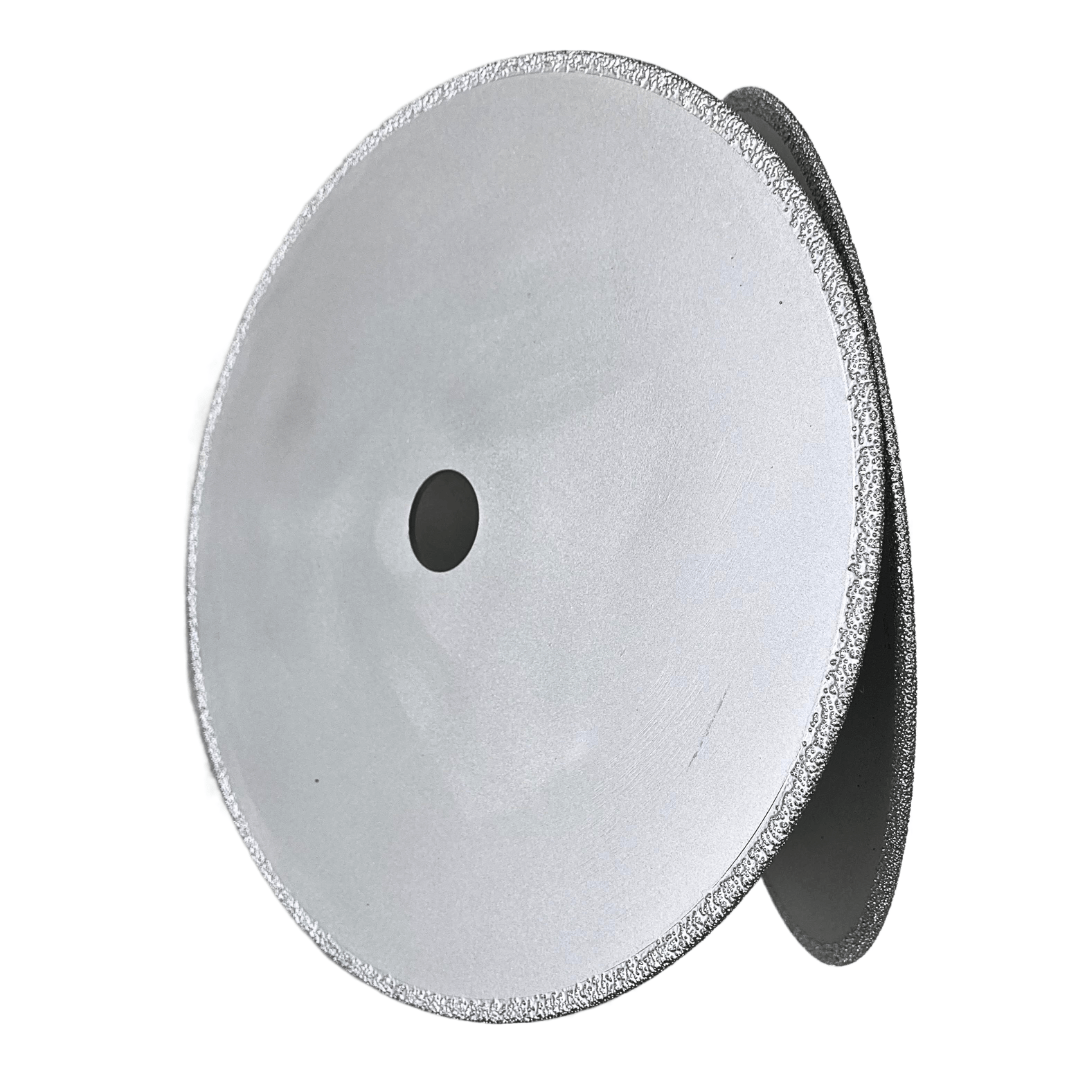

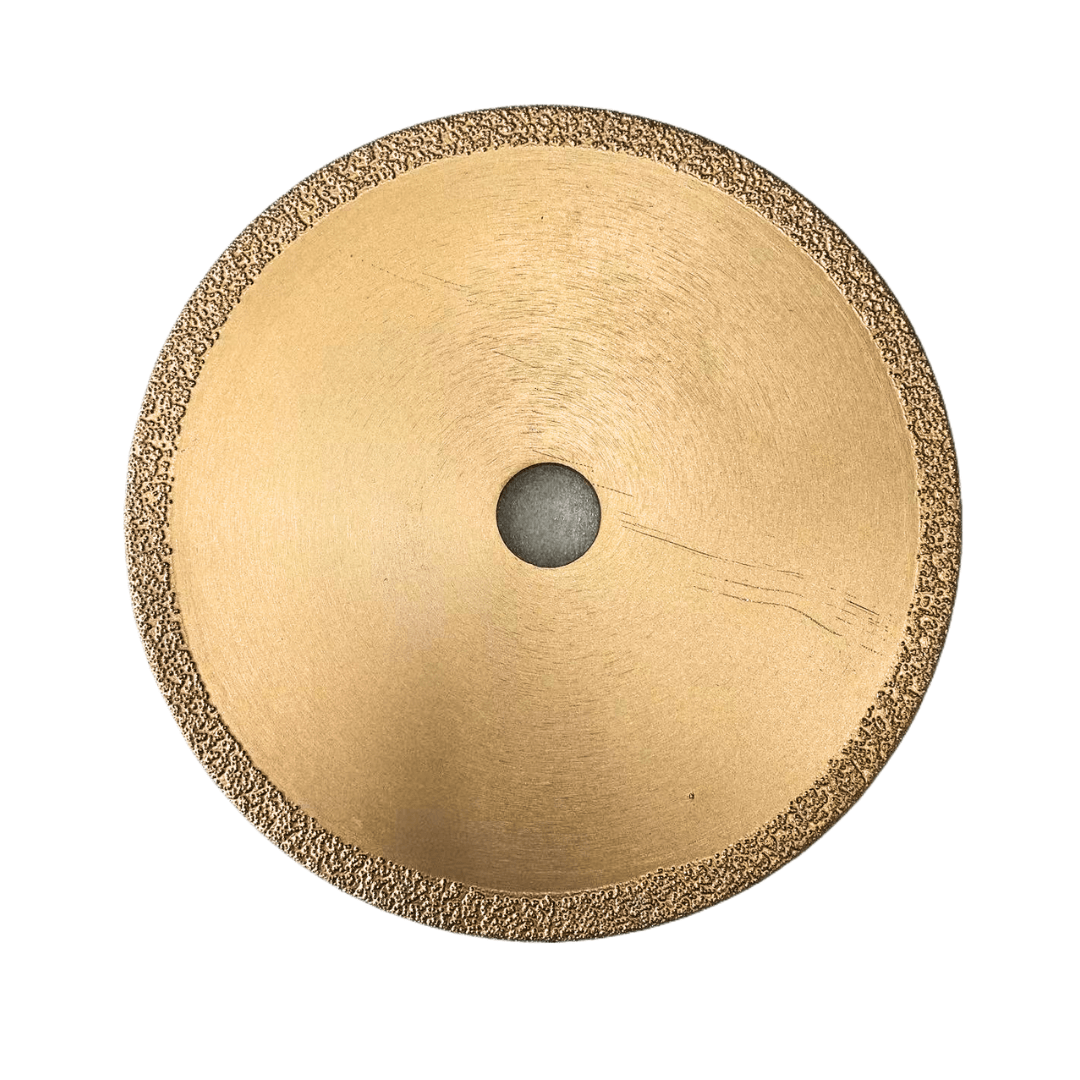

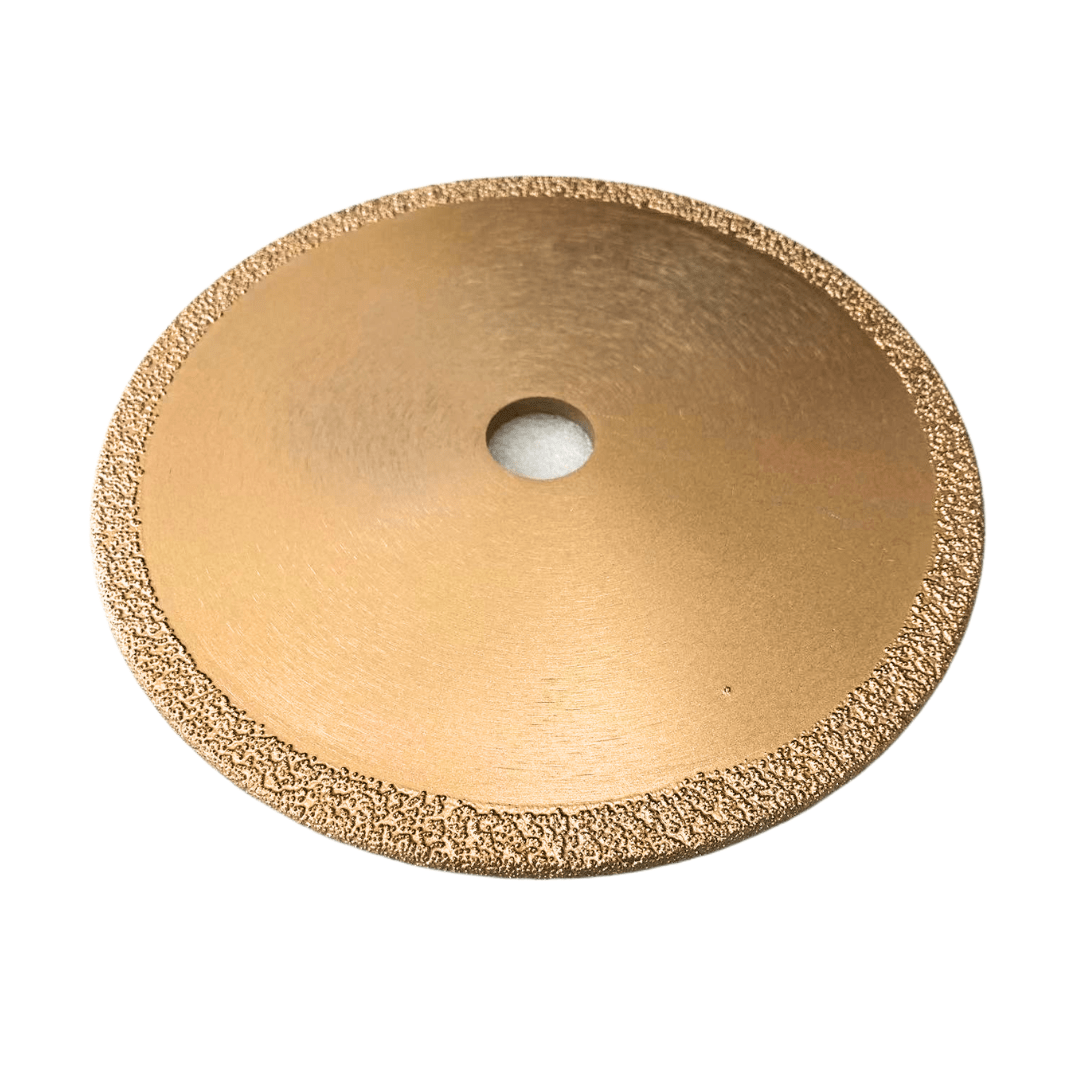

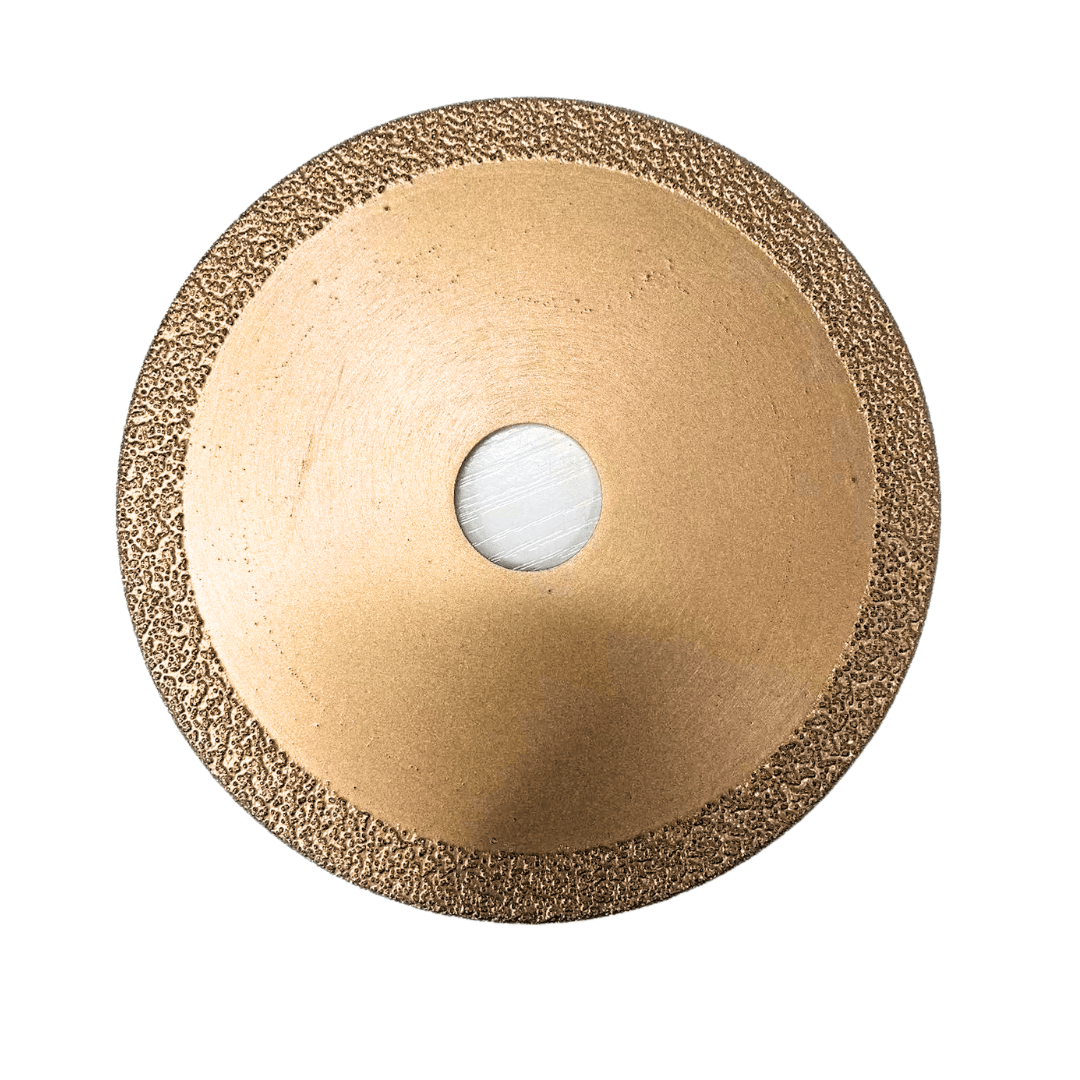

Introducing our brazing diamond cutting wheel, featuring edges embedded with high-quality diamond grains for a smooth, crack-free cut. The upgraded design ensures convenience, safety, and an extended service life. Experience minimal dust, and reduced debris for first-class cutting results. Available in various sizes, from 4 inches to 16 inches, this versatile blade easily attaches to standard angle grinders and automotive grinding machines. Widely utilized, especially in the foundry industry.

Technical Specifications

Material: diamond or CBN abrasives

Blade Base: hard steel

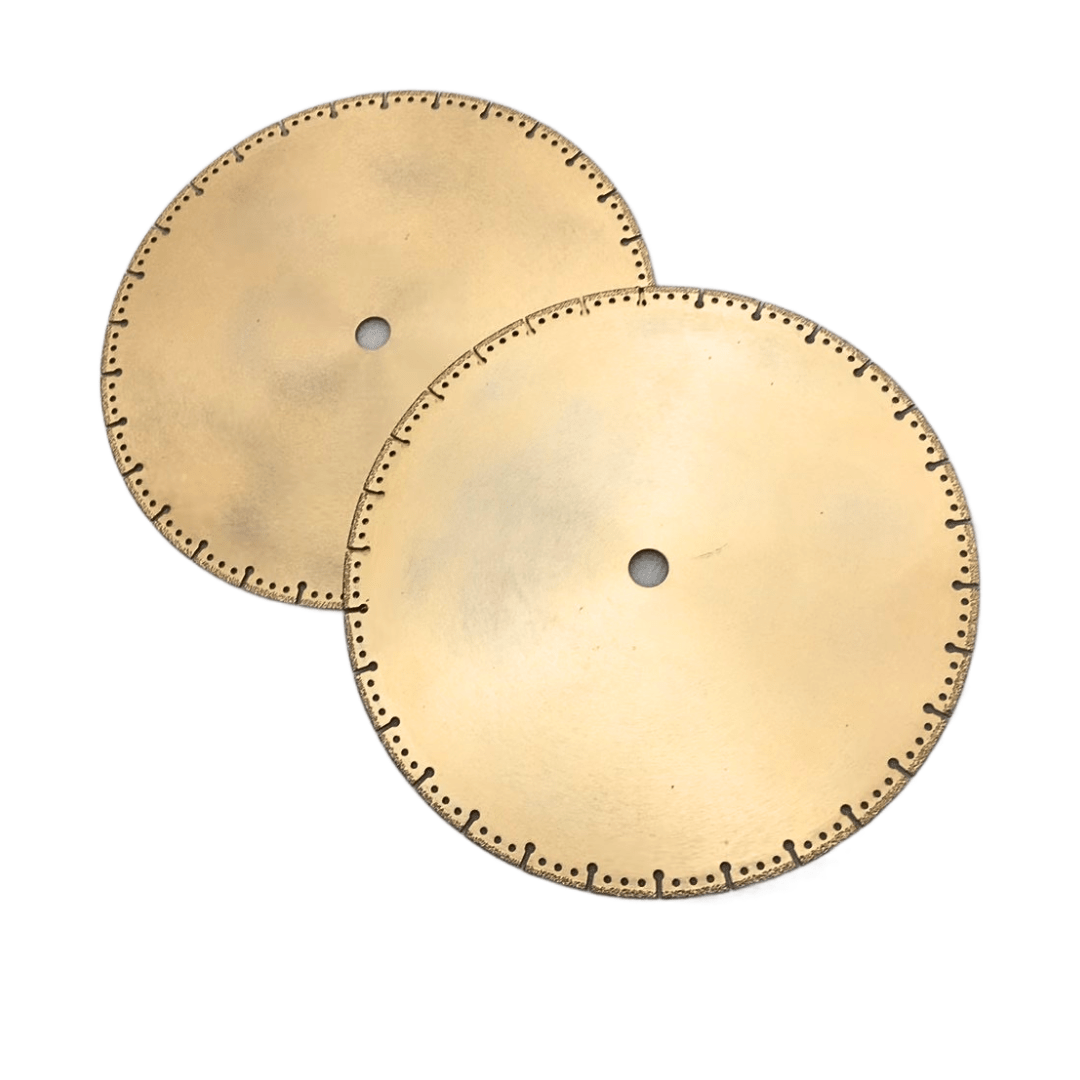

Diamond/CBN Grain Size: 30/35# 40/45#; 60#; 80#;

Outer Diameter : Available in various sizes, 100mm, 115mm, 125mm, 150mm, 180mm, 200mm, 270mm, 300mm,400mm; (4 in ,4.5 inches, 5 inches, 7 inches, 12 inches, 14 inches, 16 inches; )

Inner Bore Sizes: 16mm, 22,23mm, 25.4mm, 40mm, 75mm, (5/8 inch, 7/8 inch, 1 inch,) customization offered;

Cutting Blade Thickness: 1.5-3mm

Technology Type: vacuum brazing diamond/ CBN

Color Options: gold/silver

Features

High-Quality Diamond Particles: The use of high-quality diamond particles ensures superior sharpness and durability.

Versatile Outer Diameter: Available in multiple size options, making it suitable for cutting various workpiece sizes in the foundry industry.

Customizable Inner Bore: The inner bore sizes can be adjusted to accommodate different cutting equipment.

Exceptional Brazing Technology: First-rate brazing technology securely attaches diamond particles to the outer edge of the steel base, enhancing safety, sharpness, and durability.

Minimal Odor and Dust: These cutting discs produce less odor and dust residue compared to bonded abrasives, as they do not wear down like traditional abrasives.

CBN Alternative: These discs can be customized with CBN abrasives to cater to cutting needs for other types of steel materials.

Customization Options: The disc’s size, inner bore, and grit can be adjusted to meet specific cutting and grinding requirements.

Application

The brazing diamond cutting wheels offer versatile applications across various industries, including:

Foundry Industry:

Specifically designed for foundry applications, offering exceptional cutting performance.

Metal Cutting:

Ideal for precise and clean cutting of metals without cracking.

Concrete and Masonry Work:

Efficiently cuts through concrete and masonry materials with precision.

Tile and Stone Cutting:

Provides a flat, clean cut for tiles and stones in construction and tiling projects.

Automotive Repair:

Widely used for cutting automotive components and metal parts.

DIY Projects:

Perfect for various do-it-yourself tasks requiring accurate cutting.

Renovation and Construction:

Used in renovation projects and construction work for diverse cutting needs.

Metalworking and Fabrication:

Essential for metalworking tasks and fabricating components.

Woodworking:

Suitable for cutting wood with precision in woodworking projects.

General Cutting Applications:

Applicable in a wide range of cutting tasks across different materials and industries.

The brazing diamond cutting wheels stand out for their flat, clean cuts, enhanced safety features, and extended service life, making them a reliable choice for professionals and DIY enthusiasts in various cutting applications.