Diamond & CBN Wafering Blade

Precise and clean cut:Delivers smooth, accurate cuts with minimal burrs.

Efficient: Sharp, continuous cutting for faster processing.

Durable: Long-lasting with excellent wear resistance.

Works on larger variety of materials

Customizable: Tailored to specific cutting needs with different bonds.

Description

Precision Ultra-Thin Diamond/CBN Cutting Blades: High-Precision, High-Efficiency, and Long-Life Solutions for Difficult-to-Cut Materials

Ultra thin & high precision diamond and CBN (Cubic Boron Nitride) blades are engineered to meet the high-precision, high-efficiency, and extended lifespan demands of customers working with challenging materials. These diamond wafering blades are ideal for industries requiring accurate, specialized cutting solutions, and are widely used in the precise cutting and slotting of materials such as glass tubes, optical glass, float glass, lenses, ceramics, magnetic materials like ferrite, high-speed steel, alloy steel, and carbide.

About Cast Grind Solutions:

As your trusted provider of precision cutting solutions, Cast Grind Solutions offers customized precision diamond wafering blades designed to meet the specific requirements and operational conditions of various industries. We offer tailored services based on our clients’ unique cutting needs, ensuring optimal performance and efficiency.

Advantages of Cast Grind Solutions precision diamond & CBN Wafering Blades

Sharp Cutting and High Processing Efficiency: The Diamond and CBN blades provide precise cuts with minimal material waste, boosting productivity and reducing costs.

High Rigidity and Strength: Our high precision diamond blades are crafted for high durability, offering an extended lifespan and reliable performance even under high-pressure cutting conditions.

Non-Slip Continuous Cutting: the blades for precision cutters maintain their sharpness throughout continuous cutting without slipping or dulling, ensuring consistent results.

Precision Cuts with Smooth Edges: Ideal for precision slotting and cutting, the wafering blades produce smooth, burr-free edges, which is crucial for high-quality applications.

Key Features of Diamond Wafering Blade:

Exceptional Grinding Ability and Wear Resistance: These Diamond wafering & cut-off blades are designed for long-term use, maintaining cutting performance over extended periods of operation.

High-Rigidity Bonding: The high hardness of the bonding agent ensures that the sectioning and wafering blade retains its form during cutting, guaranteeing straight and precise cuts.

Efficient Cutting and Smooth Surface: Through careful adjustment of abrasive concentration and particle size, the sectioning blades achieve high cutting efficiency while maintaining a clean, smooth surface finish.

Advanced Manufacturing Technology: Our precision manufacturing processes ensure the high dimensional accuracy and tight tolerances of each blade.

Custom Tailored for Various Materials: Different bonding agents allow us to create specialized diamond and cbn blades for sectioning specific material types, ensuring optimum performance across industries.

Single or Multi-Blade Configurations: The Precision diamond & CBN Wafering Blades for Sectioning can be used individually or in multiple blade setups for more complex cutting applications.

Technical Specifications

High precision ultra-thin diamond and CBN wafering blades mainly include metal bond wafering blades and resin bond wafering blades.

Diamond and CBN Wafering Blades Sintered (metal bond)

Metal bond diamond wafering blades are also known as sintered or outer-ring type cutting blades. The working layer of the blade consists of diamond particles, while the central part is made from a high-strength, rigid metal matrix. Typically, these blades range in thickness from 0.2mm to 3.0mm.

- High Rigidity and Strength: The use of high-rigidity metal materials ensures that the diamond wafering blade maintains its shape during operation, reducing deformation and allowing for deep cuts and high-load operations.

- Strong Abrasive Retention: The abrasive particles are securely held in place, providing excellent wear resistance, sharpness retention, and long service life.

- Application Versatility: These wafering blades-diamond metal bond are perfect for cutting a wide range of materials, including alloys, steel, ceramics, and composites.

| D

Diameter(mm) |

T

Thickness(mm) |

H

Bore Size(mm) |

X(mm)

|

Abrasive Type | Bond Type |

| 50 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 76 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 80 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 100 | 0.2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 110 | 0.2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 125 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 140 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 150 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 160 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 175 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 180 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 200 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 250 | 1-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 300 | 1.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 350 | 2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

| 400 | 2-3 | Custom made | 3,5,10 | Diamond/CBN | Metal bond |

Applications for Metal Bond Precision Diamond Cut-off Wheels

- Ideal for high-precision cutting of materials like Zirconia ceramics, fuses, sapphire, and various glass types.

- Effective for cutting and slotting tough materials such as magnetic ferrite, high-speed steel, alloy steel, carbide, and ceramics.

Resin Bond Diamond and CBN Sectioning and Wafering Blades

Resin bond diamond and CBN blades for sectioning, also known as the outer-ring type, feature a diamond/CBN working layer around the outer circumference and a high-strength, rigid steel matrix in the center. These blades for sectioning offer high cutting efficiency and self-sharpening properties, making them well-suited for deep cuts and high-speed feed rates.

- Self-Sharpening and High Cutting Efficiency: The resin bond wafering blades maintain a sharp cutting edge throughout operation, allowing for faster, more efficient cutting of tough materials.

- Precision and Smooth Finishes: The elastic nature of the resin bond enhances the cutting process, resulting in high surface quality with minimal cracks and chips.

| D

Diameter(mm) |

T

Thickness(mm) |

H

Bore Size(mm) |

X(mm) | Abrasive Type | Bond Type |

| 50 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 76 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 80 | 0.2-2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 100 | 0.2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 110 | 0.2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 125 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 140 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 150 | 0.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 160 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 175 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 180 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 200 | 0.5-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 250 | 1-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 300 | 1.3-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 350 | 2-2.2 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

| 400 | 2-3 | Custom made | 3,5,10 | Diamond/CBN | Resin bond |

Applications for Resin Bond Sectioning and Wafering Blades:

Commonly used for cutting materials like tungsten carbide, high-boron silica glass, quartz crucibles, and silicon wafer cutting.

Precision Ultra-Thin CBN Wafering Blades

CBN wafering blades, made from cubic boron nitride, are available in both resin-bonded and sintered metal-bonded versions. CBN sectioning and wafering blades are ideal for cutting high-hardness materials, particularly those with a hardness rating of HRC 45 or higher, such as high-speed steels, tool steels, and mold steels.

Durable and Highly Efficient: CBN blades offer excellent wear resistance and high efficiency, making them perfect for industries like precision tooling and automotive parts manufacturing.

Precision Ultra-Thin Cut-off Wheel Types:

1A1 Type Ultra-Thin Blades:

The abrasive working layer is flush with the substrate thickness, offering high precision for fine slotting and cutting applications.

1A1R Type Ultra-Thin Cut off Wheel:

These blades for sectioning feature a working layer that is thicker than the substrate, allowing for better chip clearance and cooling, suitable for deeper cutting applications.

- 1A1R diamond wafering blades supply

Key Parameters:

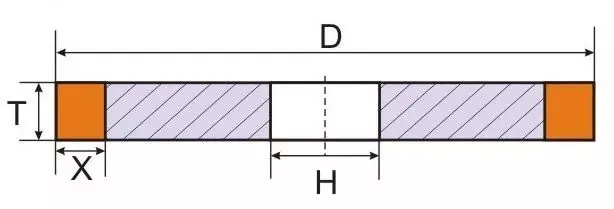

- D: Outer Diameter

- H: Inner Diameter

- X: Diamond Working Layer Width

- E: Substrate Thickness

- T: Working Layer Thickness

Features

For us to assist you in selecting the most suitable diamond wafering blade, kindly provide the following details for your precision cutting tasks:

- Specifications: Material, particle size, bond type, dimensions (outer diameter, thickness, inner diameter, etc.)

- Application Details: Workpiece name, cutting size, material type, cutting method (slotting, cutting, etc.)

- Machine and Cutting Conditions: Machine type, spindle speed, feed speed, cutting depth, dry or wet cutting, etc.

- Cutting Requirements: Desired cutting precision, edge quality, surface integrity, and any specific custom requirements.

- Special Requests: Whether you require multi-blade setups, conductive resin blades, or custom wafering blade features (e.g., water channels, chip removal grooves).

Safety Guidelines for Using Diamond Wafering Blade:

- Inspect the wafering blade for damage (chips, cracks) before installation.

- Ensure the precision cutting blade’s rotation direction matches the machine’s rotation to maintain sharpness and cutting efficiency.

- Do not use thin wafering blades that do not meet specifications or are damaged.

- If you notice unusual vibrations or sounds during operation, stop the machine immediately and inspect the blade.

- Regularly sharpen diamond wafering blades to prevent overheating and possible damage.

- Never use your hands or body to handle or guide the sectioning blade while it’s in motion.

- Avoid using cutting blades for non-designated tasks to prevent uneven stress and damage.

Application

Applications of Precision Ultra-Thin Cutting Blades:

Hard Metals: Tungsten carbide (YG8) rods and plates, high-precision molds, drill bits, PCB drill bits, etc.

Glass Cutting: Including safety fuse glass tubes, optical glass, quartz glass, and various other glass types.

Advanced Ceramics: Silicon oxide, zirconia, alumina, black ceramics, and ceramic tubes.

Gemstones & Sapphires: Cutting and slotting of sapphire and precious stones.

Magnetic Materials: Neodymium-iron-boron, silicon steel, nanocrystalline, amorphous materials, and ferrites.

Precision Optics: Cutting camera lenses, microscope lenses, and optical prisms.

Electronics & Circuit Boards: Cutting and slotting of PCB boards, semiconductors, and electronic components.

Cast Grind Solutions offers a wide range of precision ultra-thin cutting blades designed for high-performance and high-efficiency applications in industries like ceramics, glass, metalworking, and electronics. With superior cutting precision, long-lasting durability, and customizable options, our cutting solutions ensure optimal results for even the most challenging materials. Whether you’re cutting glass, ceramics, or alloys, Cast Grind Solutions provides the tools you need to achieve the highest standards of quality and precision.