Yes, a foundry is a type of metal factory. Foundries are industrial facilities dedicated to the casting process, which involves melting metals and pouring the molten material into molds to create specific shapes. The primary purpose of a foundry is to produce castings, which are solid metal objects formed by filling molds with molten metal and allowing it to cool and solidify.

In a foundry, various metals, including iron, steel, aluminum, brass, and others, can be melted and cast into different components and products. The casting process is crucial for manufacturing a wide range of metal parts used in various industries, such as automotive, aerospace, construction, energy, and more.

The operations in a foundry typically include:

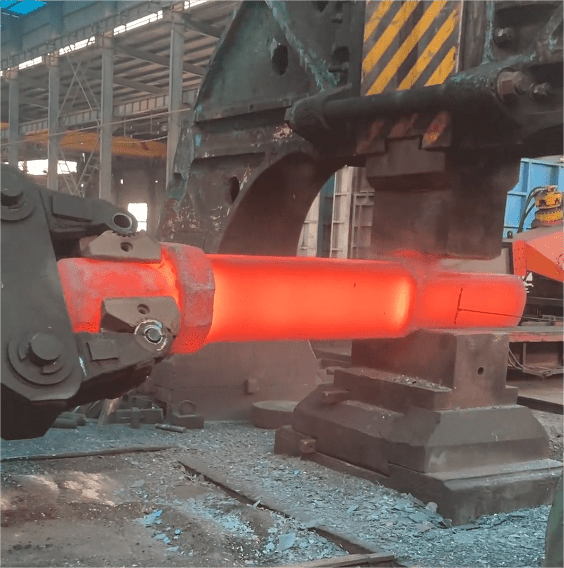

Melting: The raw metal material is heated to its melting point in a furnace to create a molten metal.

Molding: The molten metal is poured into molds, which are shaped cavities designed to create the desired form of the final product.

Cooling and Solidification: The molten metal inside the mold cools and solidifies, taking the shape of the mold.

Casting Removal: Once the metal has solidified, the casting is removed from the mold. Post-casting processes, such as cleaning, machining, and finishing, may follow.

Foundries play a crucial role in the manufacturing supply chain by providing essential components for various industries. They contribute to the production of a wide range of products, from small and intricate parts to large and heavy industrial components. The versatility of the foundry process allows for the production of complex shapes and customized components to meet specific industry requirement.