In the production of taps, white aluminum oxide grinding wheels are commonly used, and diamond dressing wheels are employed to shape them into the required geometries. However, CBN (Cubic Boron Nitride) grinding wheels differ from conventional grinding wheels in their usage and dressing parameters. As hybrid CBN grinding wheels manufacture, we’ve accumulated substantial expertise in the realm of CBN wheel dressing.

The purpose of dressing the grinding wheel is to ensure that its geometric dimensions and precision meet the requirements on a macroscopic level and to break down the abrasive grains, forming sharp edges. Generally, there are two methods for dressing grinding wheels on tap grinding machines: trajectory forming with dressing wheels and direct forming with profile dressing wheels. Below, we present the specifications for two distinct methods of applying dressings.

Trajectory Forming with Dressing Wheels

For this method, we suggest following the below parameters:

Equipment: CNC Slotting Machine

Dressing Wheel Size: 14F1 90X32XR4X16T, sintered diamond dresser

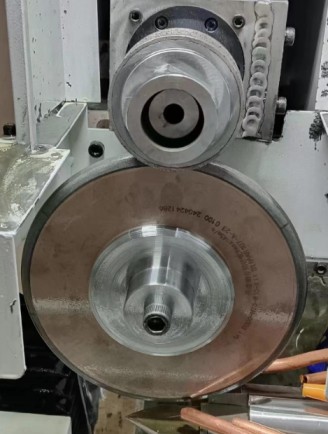

CBN Grinding Wheel Size: 1A1 200X32X10X13 B107

Objective: To dress the CBN grinding wheel into the shape required for standard φ24 tap slots.

Dressing Parameters:

Dressing Wheel Speed: 1800 RPM

CBN Grinding Wheel Speed: 1000 RPM

Dressing Depth per pass: 0.035 mm

Dressing Speed: Set at 200, with each stroke taking approximately 13 seconds

Dressing Efficiency: To dress the 1A1 grinding wheel into the desired shape took around 250 passes, consuming approximately 55 minutes.

Pre-dressing the CBN grinding wheel into an approximate shape during production can effectively reduce dressing time and dressing wheel wear.

Profile Dressing with Diamond Roller Dresser

For this method, the following parameters are suggested:

Equipment: CNC grinding Machine

Dressing Wheel Roller Size: 4XM24 taps standard diamond rotary dresser, electroplated diamond dresser

CBN Grinding Wheel Size: 1A1 200X32X10X13 B107

Objective: To dress the CBN grinding wheel into the shape required for standard φ24 tap slots.

Dressing Parameters: The CBN grinding wheel is initially pre-dressed by the grinding wheel manufacturer into an approximate shape. After mounting onto the equipment, it is dressed using the rotary diamond dresser.

Diamond Dressing Wheel Speed: 1800 RPM

CBN Grinding Wheel Speed: 1000 RPM

Dressing Process: Align the diamond roller dresser with the CBN grinding wheel and manually advance. Once the diamond dresser wheel makes contact with the CBN grinding wheel, advance by 0.01 mm and grind for 30~60 seconds. The depth of cut and grinding time is determined by the sound. Repeat this process until the diamond dressing roll is fully in contact with the CBN grinding wheel surface.

Dressing Efficiency: It takes approximately 30~60 minutes to dress the CBN grinding wheel to the required shape.

By pre-dressing the CBN grinding wheel into the approximate shape before the final dressing, both dressing time and forming roll wear can be effectively reduced, enhancing overall efficiency.

Should you encounter any challenges in the process of dressing your diamond or CBN wheels, feel free to reach out to our dedicated engineers for assistance.