In the bearing manufacturing industry, precision is paramount. Bearings are critical components in countless applications, from automotive systems to industrial machinery, and their performance depends on flawless surface finishes and exacting tolerances. At Cast Grind Solutions, we specialize in providing advanced diamond dressing tools that optimize grinding processes, delivering unparalleled efficiency, tool life, and surface finish quality.

In this article, we explore how our diamond dressing tools—CH-L02, CH-L03, and CH-L05—perform in grinding operations for two key types of bearings: deep groove ball bearings and cylindrical/tapered roller bearings.

Case Study 1: Precision Grinding of Deep Groove Ball Bearings

Workpiece: Deep Groove Ball Bearings

Material: T12, GCr15 Bearing Steel

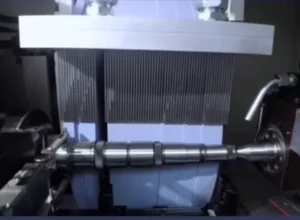

Grinding Machine: Cylindrical Grinder, Centerless Grinder

Grinding Wheel Specification: P-600x200x305 A 60#

Surface Roughness Requirement: Ra0.8-0.2μm

The Solution:

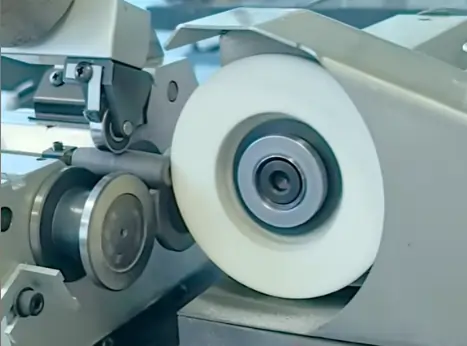

We introduced our CH-L03 and CH-L05 diamond dressing tools, designed for high-precision grinding applications.

The Results:

Efficiency: Dressing efficiency improved by 2x, significantly reducing cycle times and boosting productivity.

Tool Life: The lifespan of the tools increased by 4x, reducing replacement frequency and costs.

Surface Finish: Consistently achieved Ra0.8-0.2μm, ensuring high-quality bearings that meet stringent industry standards.

Case Study 2: Precision Grinding of Cylindrical and Tapered Roller Bearings

Workpiece: Cylindrical Roller Bearings, Tapered Roller Bearings

Material: GCr15 Bearing Steel

Grinding Machine: Cylindrical Grinder, Internal Grinder

Grinding Wheel Specification: P-500x75x203 WA 80#

Surface Roughness Requirement: Ra1.0-0.2μm

The Solution:

We implemented our CH-L02 and CH-L05 diamond dressing tools, optimized for tough materials like bearing steel.

The Results:

Efficiency: Dressing efficiency improved by 2x, enabling more components to be ground per cycle.

Tool Life: The lifespan of the tools increased by 3x, reducing downtime and maintenance costs.

Surface Finish: Consistently achieved Ra1.0-0.2μm, meeting the high standards required for roller bearings.

Why Our Diamond Dressing Tools Stand Out

Our tools are engineered to address the unique challenges of bearing manufacturing:

Precision: Achieve ultra-smooth surface finishes and tight tolerances, critical for bearing performance.

Durability: Extended tool life reduces replacement frequency and lowers operational costs.

Efficiency: Faster dressing cycles and reduced downtime boost productivity.

Cost-Effectiveness: While the initial investment may be higher, the long-term savings are substantial.

The Bigger Picture: Driving Innovation in Bearing Manufacturing

In an industry where precision and reliability are non-negotiable, the right tools can make all the difference. Our CH-L02, CH-L03, and CH-L05 diamond dressing tools have proven to be game-changers for bearing manufacturers, delivering measurable improvements in both performance and profitability.

At Cast Grind Solutions, we are committed to helping our customers overcome their grinding challenges with innovative solutions. Whether you’re producing deep groove ball bearings, cylindrical roller bearings, or tapered roller bearings, we’re here to help you achieve your goals.

Contact us today to learn more about our diamond dressing tools and how they can transform your manufacturing operations.