The cutting blade in a paper-cutting machine is a critical component, widely utilized in the printing and paper industry. The sharpness and longevity of the blades significantly influence the efficiency of the cutting process. In the production of new blades and during the grinding process for used blades, the selection of the grinding wheel becomes crucial. Most manufacturers currently utilize conventional grinding wheels to sharpen the blade edges, resulting in blades that are not sufficiently sharp and have a short lifespan.

To address this industry challenge, we’ve developed a specialized CBN (Cubic Boron Nitride) cup-shaped grinding wheel specifically designed for high-speed steel blades. Here’s how it performs:

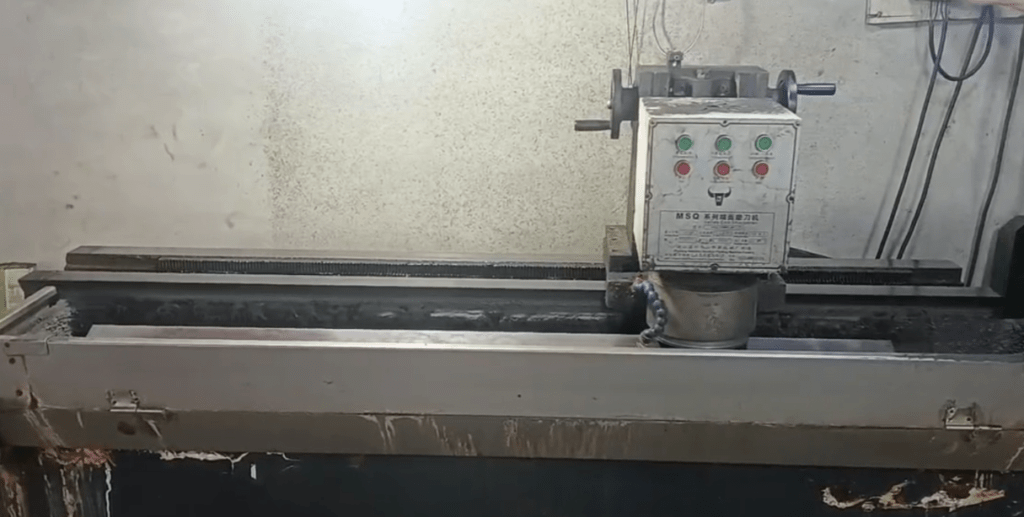

Equipment: end-face grinder

Grinding Wheel Specifications: cup wheel LB 200X100X10X12X60T

Cooling Method: Water-Soluble Grinding Fluid

Blades Application:suitable for paper-cutting applications in the printing industry.

Blade dimensions:

Paper Cutter Blade Length: 1605 mm,

Paper Cutter Blade Width: 150 mm

Paper Cutter Blade Thickness: 13 mm,

Grinding Process:

Grinding wheel speed: 2500 RPM

Return speed: 4.5 m/min

Initial grinding depth: 0.01 mm

Grind Cycles: 5-15 return trips after each 0.01 mm depth increment

Grinding Wheel Lifespan: Each CBN grinding wheel can effectively sharpen approximately 500 to 600 blades of this size.

Sharpening Period: The paper cutter blade is capable of processing between 120 to 150 reams of paper following each sharpening using the CBN cup wheel.

Customer Feedback: the CBN grinding wheel for the paper cutter blades are sharper, resulting in a crisp, clear sound when cutting paper.

Comprehensive Evaluation: By replacing traditional grinding wheels (ceramic bond aluminum oxide grinding wheel or resin bond cup wheel or pink aluminum oxide grinding wheel ) with our CBN grinding wheel, the process becomes more environmentally friendly, with no increase in grinding wheel cost. The most significant benefit is the dramatic improvement in blade sharpness and longevity, leading to higher customer satisfaction.