Precision Cutting, Grinding, and Polishing Solutions

Engineered for Excellence in Every Industry

Home>Applications>Glass and Optics Industry

Glass and Optics Industry

The glass and optics manufacturing industry demands exceptional precision, surface quality, and consistency to produce components like lenses, mirrors, display glass, and optical fibers. These components are critical for applications in electronics, automotive, medical devices, and telecommunications.At Cast Grind Solutions, we provide advanced diamond and CBN abrasive tools designed to meet the rigorous demands of this industry.

Our solutions are engineered for precision cutting, grinding, and polishing of glass, crystals, and optical materials, ensuring superior results in both manufacturing and finishing applications. Whether you’re producing lenses for cameras, display glass for smartphones, or optical fibers for telecommunications, our tools deliver the accuracy and performance needed to optimize your workflows.

Lens Grinding and Polishing

Applications: Precision shaping and finishing of optical lenses for cameras, microscopes, telescopes, and eyewear.

Solutions:

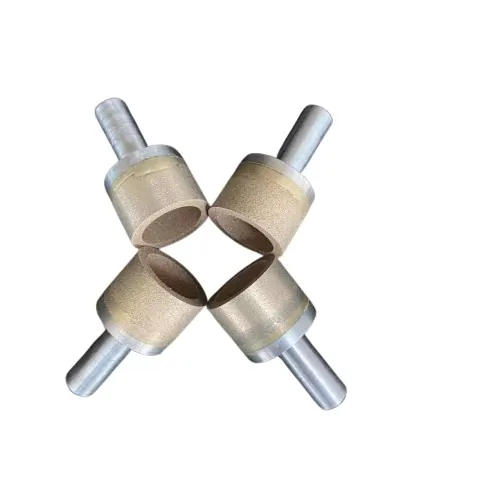

Diamond grinding wheels for rough grinding, semi-rough grinding,fine grinding and polishing.

Benefits: Tight tolerances, superior surface quality, and reduced subsurface damage.

Glass Cutting

Applications: rough and precision cutting of glass for displays, windows, architectural applications, rough and precision cutting of Soda-Lime Glass, float glass, borosilicate glass, laminated glass, crystal glass, opal glass,fiber glass, low-emissivity (Low-E)glass. Etc.

Solutions:

Diamond precision cutting wheels for clean, precise cuts with minimal chipping.

Metal bond diamond cutting wheels for K9 optical glass

Electroplated diamond cutting wheels and resin bond diamond cutting wheels for glass tubes

Resin bond precision diamond cut off wheel for Prisms

Diamond band saws for intricate shapes and curves.

Diamond wire saws for intricate shapes and curves

Benefits: High throughput, consistent edge quality, and minimal material waste.

Glass Edge Finishing

Applications: Smoothing and finishing the edges of cut glass for safety and aesthetics.

Solutions:

Diamond edge grinding wheels for glass beveling and chamfering.

Benefits: Smooth, defect-free edges with high durability and consistency.

Optical Component Machining

Applications: Precision grinding and polishing of prisms, mirrors, and optical fibers.

Solutions:

Diamond lapping film for ultra-smooth surfaces.

Diamond grinding wheels for precision shaping of hard, brittle materials.

Benefits: High optical clarity, uniform finishes, and tight dimensional control.

Sapphire Grinding and Polishing

Applications: Precision grinding and polishing of sapphire substrates for LEDs, watch crystals, and optical windows.

Solutions:

Diamond grinding wheels for rough and fine grinding.

Diamond lapping film and diamond lapping paste for high-gloss, defect-free finishes.

Benefits:

High Material Removal Rates: Efficiently grind sapphire with minimal subsurface damage.

Superior Surface Finish: Achieve ultra-smooth surfaces for enhanced optical performance.

Durability: Diamond tools resist wear, even when processing hard materials like sapphire.

Why Choose Cast Grind Solutions for Glass and Optics Applications?

Precision Tools

Achieve tight tolerances and superior surface finishes

Surface Quality

Deliver defect-free, high-gloss finishes for optical clarity

Custom Solutions

Tailored abrasives for unique geometries and requirements

Global Expertise

Trusted by foundries worldwide for reliable performance and exceptional support