Precision Cutting, Grinding, and Polishing Solutions

Engineered for Excellence in Every Industry

Home>Applications>Foundry Industry

Foundry Industry

The foundry industry is at the heart of metalworking, producing castings for a wide range of applications, from automotive and aerospace components to heavy machinery and construction equipment. In this demanding environment, precision grinding, cutting, and finishing are essential to achieve the desired surface quality, dimensional accuracy, and performance of cast parts.

Cast Grind Solutions offers pedestal grinders, diamond snagging wheels, diamond grinding discs, and cutting wheels, are specifically designed to meet the rigorous demands of foundry operations. Whether you’re removing excess material, smoothing rough surfaces, or cutting through tough cast metals, our products deliver unmatched durability, efficiency, and precision. Trusted by foundries worldwide, our solutions help you optimize productivity, reduce downtime, and achieve superior results in every application.

Cast Iron Rough Grinding Solutions

In foundry operations, rough grinding is a critical step for efficiently removing excess material, smoothing rough surfaces, and preparing cast iron components for downstream finishing processes. Our heavy-duty Cast Grind Solutions Pedestal Grinder is engineered to tackle the toughest grinding tasks with unmatched performance.

Powered by a robust motor and operating at speeds of up to 80 m/s, our grinder delivers exceptional material removal rates, significantly boosting productivity while maintaining precision. Equipped with a diamond grinding wheel and a reinforced safety guard, it ensures:

Operator Safety: The stable wheel cover minimizes debris dispersion and reduces vibration, creating a safer working environment.

Durability: Engineered for continuous use in harsh foundry conditions, with resistance to heat and wear.

Versatility: Capable of grinding cast iron components of all sizes, from small fittings to large parts like manhole covers or industrial machinery castings.

Whether you’re smoothing rough edges or preparing surfaces for coatings, our pedestal grinder combines speed, safety, and reliability to optimize your foundry workflows.

Cast Grind Solutions offers a comprehensive range of pedestal grinders designed to meet the diverse grinding needs of foundry operations. Whether you’re working on small castings or large, heavy-duty components, our grinders deliver the performance, durability, and precision you need to optimize your workflows.

If you have any questions or need assistance in selecting the right grinder for your application, our team is here to help. Contact us today to discuss your requirements and discover how our solutions can enhance your foundry operations.

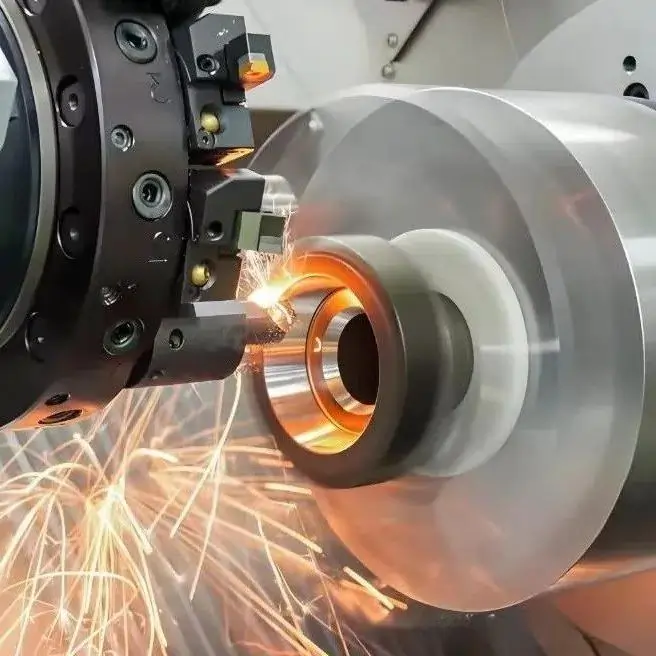

Heavy-Duty Grinding for Cast Iron and Steel

In the demanding environment of foundries and metalworking facilities, heavy-duty grinding is essential for shaping, smoothing, and finishing large cast iron and steel components.

Cast Grind Solutions offers a wide range of fettling wheels in sizes from 100mm to 750mm diameter, designed to meet the diverse heavy-duty grinding needs of the foundry industry. Whether you’re working on small, intricate castings or large, robust components, our grinding tools are built to deliver exceptional performance and durability.

Our heavy-duty grinding solutions, including diamond grinding wheels, grinding discs, and grinding heads, are engineered to withstand the rigors of grinding:

Engine Blocks and Cylinder Heads for automotive applications.

Gear Housings and Turbine Casings for industrial machinery.

Brake Discs, Flywheels, and Manhole Covers for construction and infrastructure.

Hydraulic Components and Valve Bodies for precision engineering.

Whether you’re working on railway components, marine propeller housings, or construction equipment parts, our heavy-duty grinding solutions are built to maximize productivity, reduce downtime, and deliver superior results.

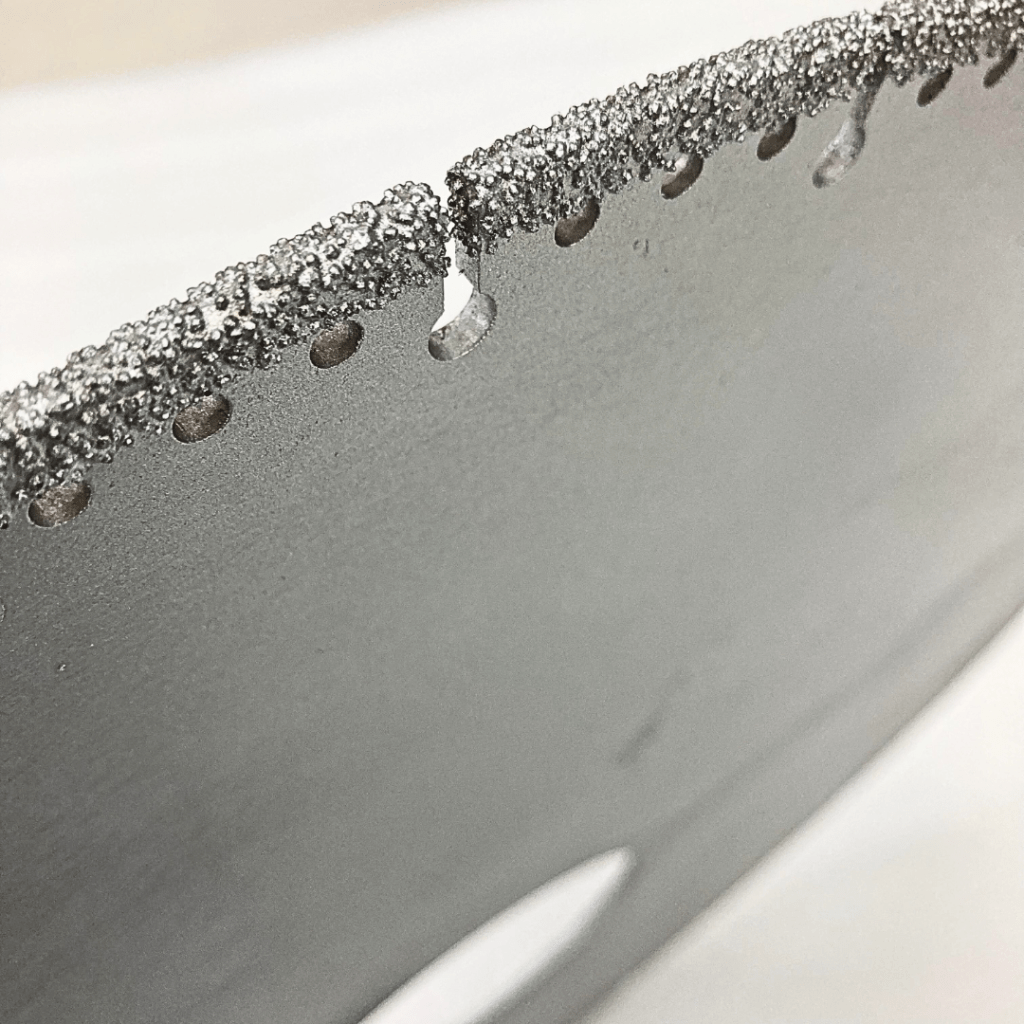

Efficient Cutting-Off of Casting Parts

In foundry operations, cutting off excess material, risers, and gates from castings is a critical step in preparing components for further processing. Cast Grind Solutions cutting tools are designed to deliver precision, speed, and durability, ensuring efficient and cost-effective cutting-off of casting parts.

Our diamond cutting wheels ,diamond saw blades and CBN cutting discs are engineered to handle the toughest materials, including cast iron, steel, and alloy castings. With advanced abrasives and robust construction, they provide:

High Cutting Speeds: Reduce processing time and improve productivity.

Clean, Precise Cuts: Minimize material waste and ensure smooth edges for downstream finishing.

Exceptional Durability: Resist wear and heat, even in continuous use, for longer tool life.

Whether you’re cutting off risers from engine blocks, gates from gear housings, or excess material from structural castings, our cutting tools are built to maximize efficiency and deliver consistent results.

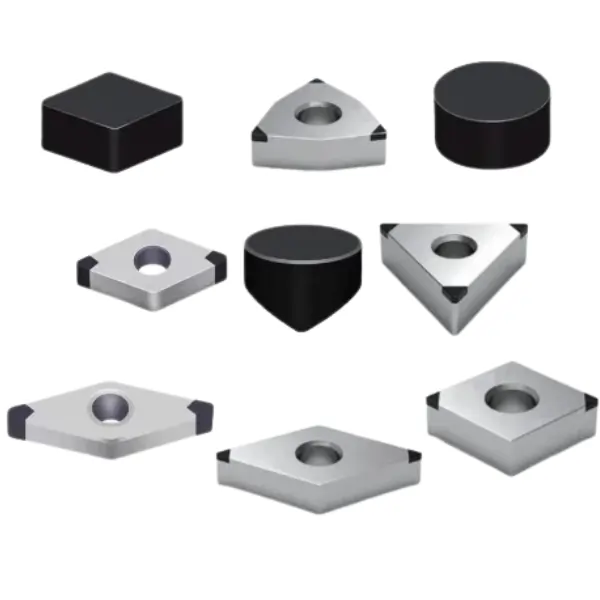

PCD and PCBN Inserts and Cutters for Foundry Applications

In the foundry industry, machining cast iron, hardened steel, and other abrasive materials requires tools that can withstand extreme wear and heat. Polycrystalline Diamond (PCD) and Polycrystalline Cubic Boron Nitride (PCBN) inserts and cutters are ideal for these demanding applications, offering exceptional durability and cutting performance. At Cast Grind Solutions, we provide advanced grinding solutions for manufacturing and reconditioning PCD and PCBN tools, ensuring they deliver optimal results in foundry operations.

PCBN inserts excel in high-speed machining of gray and ductile cast iron components such as engine blocks, cylinder heads, and brake discs, offering extended tool life and consistent performance. For hardened steel parts like gears, shafts, and dies, PCBN tools provide high wear resistance and reduced heat generation, ensuring precise results and improved surface quality. Additionally, PCD cutters are ideal for cutting and shaping abrasive materials like composites and ceramics, delivering minimal tool wear and high cutting speeds.

Why Choose Cast Grind Solutions for Foundry Applications?

Precision Tools

Achieve tight tolerances and superior surface finishes

Durability

Tools designed for heavy-duty use in harsh environments

Versatility

Suitable for cast iron, steel, and other foundry materials

Custom Solutions

Tailored abrasives for unique geometries and requirements

Global Expertise

Trusted by foundries worldwide for reliable performance and exceptional support