In the automotive parts manufacturing process, precision grinding is a critical step to ensure product quality. The grinding wheel, as the core tool in grinding operations, directly impacts the machining accuracy and surface finish of workpieces. Diamond dressing tools (diamond dressers) play a vital role in maintaining grinding wheel performance. This article explores the application of diamond dressing tools in the manufacturing of automotive drive shafts and universal joints through two real-world cases, highlighting their significant improvements in efficiency and tool life.

Case 1: Precision Grinding of Large Automotive Drive Shafts

Workpiece: Large Automotive Drive Shaft

Material: Medium Carbon Steel

Grinding Machine: CNC Cylindrical Grinder

Grinding Wheel Size: 400*40*203

Grinding Wheel Specification: SA 400x40x203 A 60L

Grinding Method: Precision Grinding

Surface Roughness Requirement: Ra0.2μm

Previous Tool: Diamond Dresser from Another Supplier

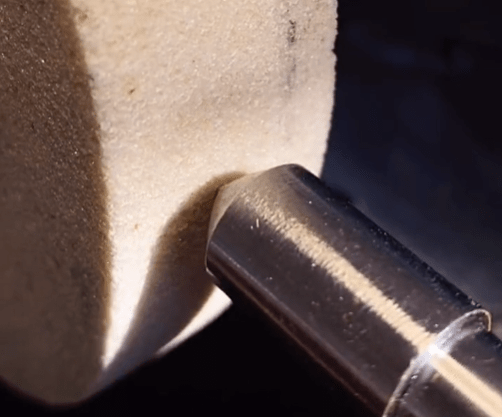

Current Tool: Cast Grind Solutions diamond dresser

Efficiency Ratio: 1:1.5

Tool Life Ratio: 1:2

Analysis and Results:

In the precision grinding of drive shafts, the quality of wheel dressing directly affects the surface finish and dimensional accuracy of the workpiece. Initially, the customer used a diamond dresser from another supplier, which met basic dressing requirements but fell short in terms of efficiency and tool life.

After switching to the Cast Grind Solutions diamond dresser, dressing efficiency improved by 50%, significantly reducing wheel dressing time and increasing overall production efficiency. Additionally, the Cast Grind Solutions tool life was twice that of the previous tool, greatly reducing tool replacement frequency and costs. As a result, the surface roughness of the drive shafts consistently achieved Ra0.2μm, fully meeting the customer’s precision requirements.

Case 2: Semi-Finish and Precision Grinding of Automotive Universal Joints

Workpiece: Automotive Universal Joint

Material: Ductile Iron

Grinding Machine: Cylindrical Grinder

Grinding Wheel Size: 500*75*203

Grinding Wheel Specification: GC 500x75x203 WA 80K

Grinding Method: Semi-Finish and Precision Grinding

Surface Roughness Requirement: Ra1.6-0.4μm

Previous Tool: Single-Point Natural Diamond Dresser

Current Tool: Cast Grind Solutions CH-L05

Efficiency Ratio: 1:1.8

Tool Life Ratio: 1:3

Analysis and Results:

In the machining of automotive universal joints, the properties of ductile iron place higher demands on wheel dressing. The customer initially used a single-point natural diamond dresser, which could perform basic dressing tasks but lacked efficiency and durability, especially during semi-finish and precision grinding. Frequent dressing and tool changes led to reduced production efficiency and increased downtime and maintenance costs.

After switching to Cast Grind Solutions diamond dresser, dressing efficiency improved by 80%, significantly shortening wheel dressing cycles and boosting overall production efficiency. Moreover, the Cast Grind Solutions tool life was three times that of the previous tool, reducing tool replacement frequency and long-term costs. Ultimately, the surface roughness of the universal joints was consistently maintained within the Ra1.6-0.4μm range, fully meeting the customer’s high-precision machining requirements.

Key Advantages of Diamond Dressing Tools

The above cases demonstrate the outstanding performance of Cast Grind Solutions diamond dressing tools in automotive parts manufacturing. Their key advantages include:

High Dressing Efficiency: Dressing efficiency improved by 50%-80%, significantly reducing wheel dressing time and increasing production efficiency.

Extended Tool Life: Tool life is 2-3 times longer than conventional tools, greatly reducing replacement frequency and maintenance costs.

Superior Precision: Ensures consistent wheel dressing quality, achieving surface roughness of Ra0.2μm (drive shafts) and Ra1.6-0.4μm (universal joints), meeting high-precision machining demands.

Cost-Effectiveness: While the initial investment is higher, long-term costs are significantly reduced, offering excellent value for money.

Conclusion

In the automotive parts manufacturing industry, diamond dressing tools are essential for improving machining efficiency and reducing production costs. As demonstrated by the real-world cases above, Cast Grind Solutions diamond dressers deliver exceptional performance in the grinding of automotive drive shafts and universal joints, not only enhancing production efficiency but also significantly extending tool life, providing customers with substantial economic benefits.

If you are seeking an efficient, durable, and cost-effective wheel dressing solution, contact us today to learn more about our products and technical support!