The best tool for grinding cast iron depends on the specific task at hand and the preferences of the user. Here are some common tools used for grinding cast iron:

Angle Grinder:

An angle grinder is a versatile handheld power tool that is commonly used for grinding and cutting tasks. It can accommodate various abrasive discs or wheels suitable for cast iron grinding. Use a grinding wheel or flap disc designed for metal.

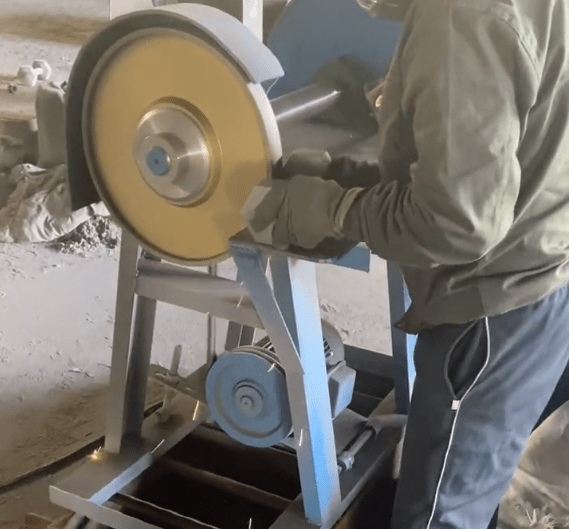

Bench Grinder:

A bench grinder is a stationary tool with grinding wheels mounted on both ends. It’s suitable for sharpening tools and grinding small to medium-sized cast iron pieces. It allows for precise control and steady handling.

A pedestal grinder is an enlarged variant of a bench grinder, affixed to a pedestal securely bolted to the floor. This grinder is frequently employed for manually grinding cutting tools and conducting coarse grinding tasks on small to medium-sized cast iron components.

Die Grinder:

A die grinder is a handheld rotary tool that is often used for precision grinding in smaller areas or for intricate work. It’s suitable for tasks that require detailed grinding, such as deburring or shaping.

Belt Sander:

A belt sander equipped with a coarse-grit abrasive belt can be effective for removing material quickly from larger cast iron surfaces. It’s suitable for leveling and shaping applications.

Flap Discs:

Flap discs are versatile abrasive tools that can be used with an angle grinder. They consist of overlapping abrasive flaps that provide a smoother finish compared to traditional grinding wheels. They are effective for both grinding and finishing.

Grinding Wheel:

A traditional grinding wheel designed for metalworking is a common choice for grinding cast iron. These wheels are available in various grits for different levels of material removal and finishing.

Here, we recommend the use of diamond grinding wheels, which are significantly more efficient than traditional aluminum or zirconium grinding wheels for cast iron friction.

Dremel Tool:

For smaller, intricate tasks or areas that are hard to reach, a rotary tool like a Dremel with appropriate attachments can be used for grinding cast iron.

Tips for Choosing the Right Tool:

Consider the size of the cast iron piece and the level of precision required.

Choose an abrasive tool (wheel, disc, or belt) with the appropriate grit for the task.

Ensure that the tool’s speed and power are suitable for grinding metal.

Use safety equipment such as goggles, hearing protection, and gloves.

It’s crucial to match the tool to the specific requirements of your cast iron grinding task. Always follow the manufacturer’s guidelines for both the tool and the abrasive material, and practice proper safety precautions during use.