Electroplated CBN Gear Grinding Wheels: Precision Solutions for High-Performance Gear Manufacturing

Introduction

In the world of precision gear grinding, achieving micron-level accuracy, superior surface finishes, and extended tool life is critical. Electroplated CBN (Cubic Boron Nitride) gear grinding wheels have become the industry standard for high-performance applications, offering unmatched durability and efficiency compared to conventional abrasives.

Whether you’re manufacturing aerospace gears, automotive transmissions, wind turbine components, or robotics systems, electroplated CBN wheels deliver consistent results for hardened steel and superalloys.

In this post, we’ll explore:

- What Are Electroplated CBN Gear Grinding Wheels?

- What makes electroplated CBN gear grinding wheels unique?

- Key advantages over traditional grinding wheels

- Top applications in high-precision industries

- How to choose the right CBN wheel for your needs

- Top Brands of Electroplated CBN Gear Grinding Wheels in the Global Market

What Are Electroplated CBN Gear Grinding Wheels?

An electroplated CBN profile grinding wheel consists of a single layer of CBN abrasive grains bonded to a steel or aluminum core using an electroplating (nickel-bond) process. This creates an ultra-durable, high-precision grinding surface ideal for:

- Gear profile grinding (involute, cycloidal, and custom shapes)

- Hardened steel grinding (45-65 HRC)

- High-speed machining (80-150 m/s)

Key Features:

- Single-layer CBN wheel – No dressing required, maintaining consistent form accuracy.

- Non-dressable CBN wheel – Eliminates downtime for truing.

- Precision CBN grinding wheel – Achieves IT4-IT6 tolerances.

- CBN wheel for hardened steel – Ideal for Heat-Treated Gear, bearings, and tool steels.

Why Choose Electroplated CBN Over Conventional Wheels?

| Feature | Electroplated CBN Wheel | Vitrified CBN Wheel | Aluminum Oxide Wheel |

| Dressing Required? | No | Yes | Yes |

| Tool Life | Extremely Long (1000+ gears) | Long (500+ gears) | Short (50-100 gears) |

| Grinding Speed | 80-150 m/s (High-Speed) | 30-80 m/s | 20-50 m/s |

| Surface Finish (Ra) | 0.2-0.4 μm (Mirror Finish) | 0.4-0.8 μm | 0.8-1.6 μm |

| Best For | Hardened steels, aerospace, automotive | Hardened steels, aerospace, automotive | Soft materials, Hardened steels, aerospace, automotive |

Advantages of Electroplated CBN Form Grinding Wheels:

- No dressing needed – Save time and maintains profile accuracy.

- Longer lifespan – Reduces replacement costs.

- Faster grinding speeds – Increases productivity.

- Superior surface finish – Minimizes post-grinding polishing.

- Ideal for complex profiles – CBN gear profile grinding wheels are perfect for complex gear grindingTop

Applications of CBN Profile Grinding Wheel

CBN profile grinding wheels deliver precision grinding for critical applications: high-speed aerospace gears, durable automotive transmissions (EV and traditional), large wind turbine components, ultra-precise robotics gears (<1 arc-minute backlash), and optimized EV motor gears for reduced power loss. Nickel-bond CBN grinding wheels are Ideal for demanding industries.

Based on our 20+ years of experience in the CBN gear grinding wheel industry, we have further classified CBN profile grinding wheels into the following categories according to their specific applications across different industries:

Internal Gear & Slot CBN Grinding Wheel

Precision grinding solutions for internal gears, keyways, and arc channels in automotive transmissions and aerospace applications.

Key Features:

- Single-pass roughing & finishing (no dressing required)

- Maintains 0.003mm profile accuracy

- Compatible with NC gear grinders

- Recyclable for extended use

Specifications:

| Material | Grit Size | Diameter (mm) | Bore (mm) | Thickness (mm) |

| CBN | D91 | 10-60 | 3-10 | 5-10 |

| CBN | D54-D25 | Custom | Custom | Custom |

Ideal for high-precision internal gear machining with unmatched efficiency.

Precision CBN Gear Grinding Wheel

Advanced solution for external gear and screw tooth finishing across industries

Applications:

- Automotive transmissions

- Wind power gearboxes

- Aerospace components

- Industrial reducers

Technical Advantages:

- High-speed NC grinder compatible (single-pass roughing & finishing)

- Eliminates dressing requirements

- Maintains 0.003mm profile accuracy

- Fully recyclable construction

Specifications:

| Material | Grit Size | Diameter (mm) | Bore (mm) | Thickness (mm) |

| CBN | D126-D91 | 10-150 | 5-40 | 5-40 |

| CBN | D54-D25 | Custom | Custom | Custom |

Redefining gear grinding efficiency with patented CBN technology

Precision Groove & Arc CBN Grinding Wheel

Specialized solution for complex channel grinding in critical applications

Primary Applications:

- Robot RV reducer pin housings

- Automotive transmission components

- Aerospace inner gear ring channels

Technical Specifications:

| Parameter | Specification Range |

| Material | CBN |

| Grit Size | D181-D91 (Standard), D54-D25 (Precision) |

| Diameter | 10-100mm |

| Bore Size | 5-40mm |

| Thickness | 5-40mm |

Key Features:

- 0.003mm profile accuracy

- Compatible with Magerle, Kapp Niles, Liebherr grinders

- Single-operation finishing (no secondary processing)

- Recyclable construction for cost efficiency

Performance Advantages:

- Maintains tight tolerances for critical groove profiles

- Eliminates multiple grinding passes

- Reduces tooling costs through recyclability

- Engineered for precision grinding of complex arc channels in demanding industrial applications

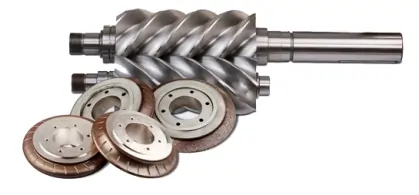

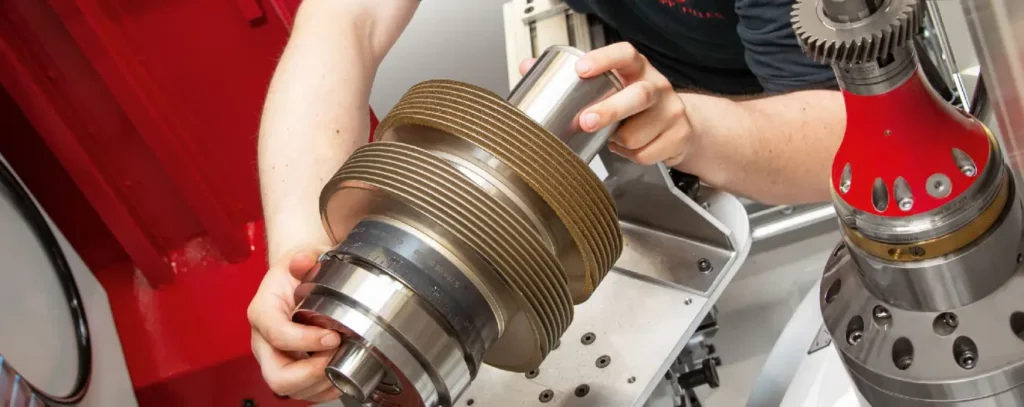

Precision Stator & Rotor CBN Grinding Wheel

Optimized for high-accuracy screw rotor finishing

Key Applications:

- Pre-finish and final grinding of:

- Steel screw rotors

- Cast iron screw rotors

Technical Specifications:

| Feature | Specification |

| Grinding Material | CBN |

| Particle Size | D213-D151 (Standard) |

| Particle Size | D91-D76 (Fine Finishing) |

| Diameter Range | 180-300mm |

| Bore Size | 40-80mm |

| Thickness | 40-120mm |

Performance Features:

- Achieves 0.003mm profile accuracy

- Compatible with KAPP NILES RX 120 rotor grinders

- Recyclable design reduces operational costs

- Suitable for both pre-finish and final grinding operations

Machine Compatibility:

Specifically engineered for KAPP NILES RX 120 rotor grinding systems

Quality Assurance:

- Maintains consistent precision through multiple uses

- Delivers superior surface finish quality

- Optimized for high-volume production environments

- Engineered for exceptional accuracy in compressor and vacuum pump rotor manufacturing

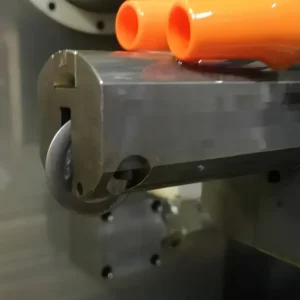

Precision CBN Slotting Wheel

High-performance solution for precision slot grinding on hardened shafts

Primary Applications:

- Gearbox shafts

- Transmission shafts

- Steering racks

- Other automotive transmission and steering components

Technical Specifications:

| Parameter | Specification Range |

| Material | CBN |

| Grit Size | D213-D151 (Standard) |

| Grit Size | D91-D76 (Fine Finishing) |

| Diameter | 200-500mm |

| Bore Size | 40-200mm |

| Thickness | 5-100mm |

Performance Characteristics:

- Maximum operating speed: 120 m/s

- Recommended operating speed: 80-100 m/s

- Single-pass grinding capability

- Eliminates pre-turning requirements

- Forms precise slots in hardened materials

Key Advantages:

- Achieves complete groove profiles in one operation

- Maintains dimensional accuracy on hardened shafts

- High-speed capable for production efficiency

- Suitable for various slot configurations

Process Benefits:

- Reduces machining steps

- Improves production throughput

- Maintains tight tolerances

- Extends tool life through CBN durability

- Engineered for high-precision slot grinding in demanding automotive applications

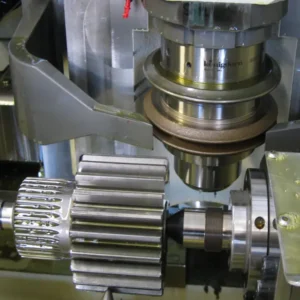

Precision CBN Worm Continuous Grinding Wheel

Ultra-efficient solution for high-accuracy gear profile grinding

Key Features:

- Electroplated CBN construction for maximum durability

- Processes both cylindrical and globoidal gear forms

- Continuous division capability for uninterrupted grinding

- Exceptional tooth graduation precision

- Custom-engineered for specific applications

Technical Capabilities:

- Generates precise external gear profiles

- Handles complex interfering contours

- Maintains tight tolerances throughout operation

- Optimized for high-volume production

Machine Compatibility:

Designed for KAPP NILES grinding systems

Integrates with profile grinding wheels

Supports continuous generating motion

Custom Specifications:

| Parameter | Availability |

| Material | CBN |

| Diameter | Fully Customizable |

| Bore Size | Custom Solutions |

| Thickness | Tailored Designs |

Performance Advantages:

- 40% faster cycle times vs conventional methods

- Maintains ±0.002mm profile accuracy

- Reduces setup changes through continuous operation

- Extends service life through premium CBN construction

Ideal For:

- High-precision automotive gears

- Aerospace transmission components

- Industrial gearbox manufacturing

- Robotics reducer systems

- Engineered for maximum productivity in demanding gear grinding applications

How to Select the Right Nickel-bond CBN profile grinding wheel?

When buying electroplated CBN gear grinding wheels, consider:

- Material Hardness – Best for >45 HRC steels.

- Gear Profile Complexity – Custom CBN form grinding wheels for unique tooth forms.

- Machine Compatibility – Works with KAPP, Reishauer, Gleason grinders.

- Coolant Type – Oil-based recommended for heat control.

For custom electroplated CBN wheels for gears, consult a precision CBN grinding wheel manufacturer to match your specs. Or contact us for professional guide and suggestions.

Top Brands of Electroplated CBN Gear Grinding Wheels in the Global Market

When it comes to high-precision CBN gear grinding wheels, several international manufacturers stand out for their cutting-edge technology and reliability. Here are the most renowned brands in the industry:

- KAPP NILES (Germany)

Specialty: Ultra-precise CBN profile grinding wheels for automotive and aerospace gears.

Key Feature: Optimized for KAPP RX and VX series gear grinders.

Applications: EV transmission gears, turbine engine components.

- Reishauer (Switzerland)

Specialty: CBN form grinding wheels for high-volume gear production.

Key Feature: Used in Reishauer RZ and NZ grinding machines.

Applications: Precision gears for robotics, wind turbines.

- 3M (USA)

Specialty: Electroplated CBN wheels with advanced grain technology.

Key Feature: Long lifespan for hardened steel and superalloys.

Applications: Aerospace, defense, and medical gear systems.

- Tyrolit (Austria)

Specialty: High-speed CBN grinding wheels for industrial gear manufacturing.

Key Feature: Hybrid bonds for extended durability.

Applications: Heavy-duty gearboxes, wind energy components.

- Noritake (Japan)

Specialty: Superabrasive CBN wheels for fine-finishing applications.

Key Feature: Ultra-fine grit options (up to #4000).

Applications: High-precision robotics and optical device gears.

- Saint-Gobain Abrasives (Norton | USA/France)

Specialty: Custom electroplated CBN wheels for complex profiles.

Key Feature: Tailored solutions for KAPP, Gleason, and Höfler machines.

Applications: Automotive, aerospace, and space industry gears.

- Cast Grind Solutions (China)

Cast Grind Solutions specializes in manufacturing high-precision electroplated CBN grinding wheels for gear forming. With 20+ years of expertise and world-class equipment, we serve automotive, aerospace, wind power, robotics (RV reducers), and new energy sectors, delivering industry-leading, competitive solutions.

Specialty: High-performance electroplated CBN gear grinding wheels for demanding applications.

Key Feature: Advanced nickel-bond technology for superior wear resistance and precision.

Applications: Automotive transmissions, wind turbine gears, aerospace components, and robotics.

Why Choose Us?

✔ Custom Solutions – Tailored CBN wheels for specific gear profiles and materials.

✔ Competitive Pricing – High-quality abrasives at cost-effective rates.

✔ Global Supply – Reliable delivery and technical support worldwide.

Why Trust These Leading Brands?

✔ Proven Performance – Trusted by Tier 1 gear manufacturers (e.g., ZF, Bosch, Boeing).

✔ R&D-Backed Technology – Continuous innovation in grain and bond formulations.

✔ Global Support – Technical service and quick delivery worldwide.

Need a high-precision CBN grinding wheel? Contact Cast Grind Solutions today for a customized quote!

Conclusion

Electroplated CBN gear grinding wheels revolutionize high-precision manufacturing with their long life, speed, and accuracy. Whether for aerospace, automotive, wind energy, or robotics, these wheels deliver unmatched performance.

Are you using electroplated CBN wheels in your gear production?

For expert advice on selecting the right gear grinding solution with precision CBN grinding wheels, contact us today!