Precision Cutting, Grinding, and Polishing Solutions

Engineered for Excellence in Every Industry

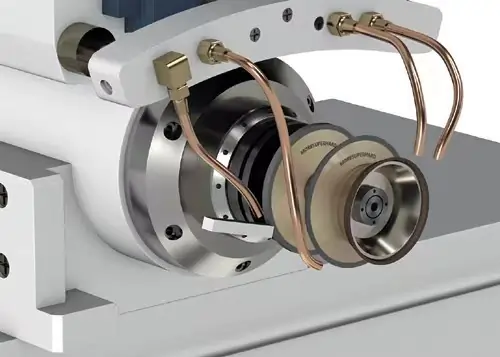

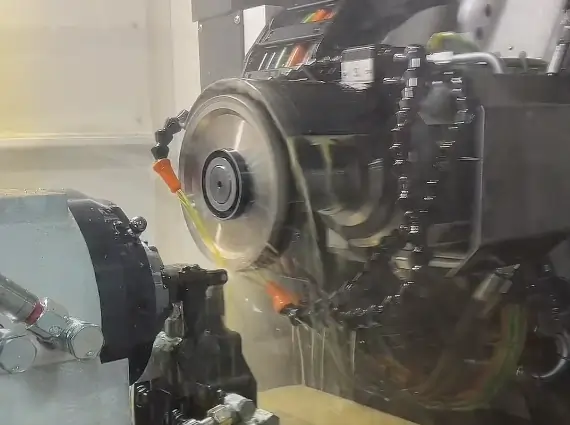

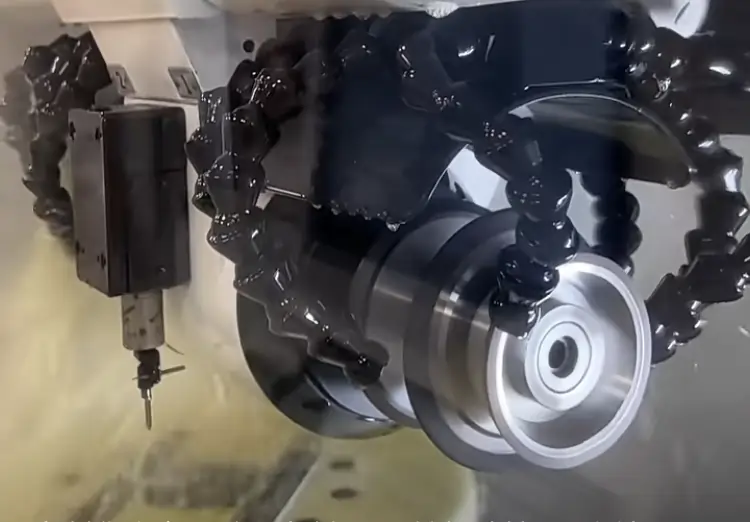

CNC Tool and Cutter Grinding Industry

The CNC tool and cutter grinding industry demands precision, versatility, and efficiency to produce and maintain cutting tools for a wide range of applications. From end mills and drills to reamers and inserts, the quality of abrasive tools directly impacts the performance, accuracy, and lifespan of CNC tools. At Cast Grind Solutions, we provide advanced diamond and CBN grinding wheels and abrasive tools designed to meet the rigorous demands of this industry.

Our solutions are engineered for precision grinding, sharpening, and finishing of CNC tools, ensuring superior results in both manufacturing and reconditioning applications. Whether you’re producing new tools or restoring worn ones, our tools deliver the accuracy and performance needed to optimize your workflows.

Key Applications in CNC Tool and Cutter Grinding

End Mill Grinding

Applications: Grinding and sharpening end mills for milling operations.

Solutions:

Hybrid grinding wheel for end mill fluting

Diamond and CBN grinding wheels for precise flute and edge grinding.

Custom bond types for HSS, carbide, and coated tools.

Benefits: Sharp, durable cutting edges for efficient material removal and extended tool life.

Drill Bit Sharpening

Applications: Sharpening twist drills, step drills, and carbide drills.

Solutions:

Diamond grinding wheels for carbide drills.

CBN grinding wheels for HSS drills.

Hybrid grinding wheels for twist drills, step drills, carbide drills fluting and grooving

Benefits: Restored cutting performance, reduced heat generation, and consistent hole quality.

Reamer Grinding

Applications: Grinding and finishing reamers for precise hole sizing and finishing.

Solutions:

Diamond and CBN grinding wheels for flute and edge grinding.

PVA polishing wheels for high-gloss finishes.

Rubber polishing wheels for reamers polishing

Benefits: Tight tolerances, smooth finishes, and extended tool life.

Insert Grinding

Applications: Grinding and sharpening carbide inserts and ceramic inserts for turning and milling.

Solutions:

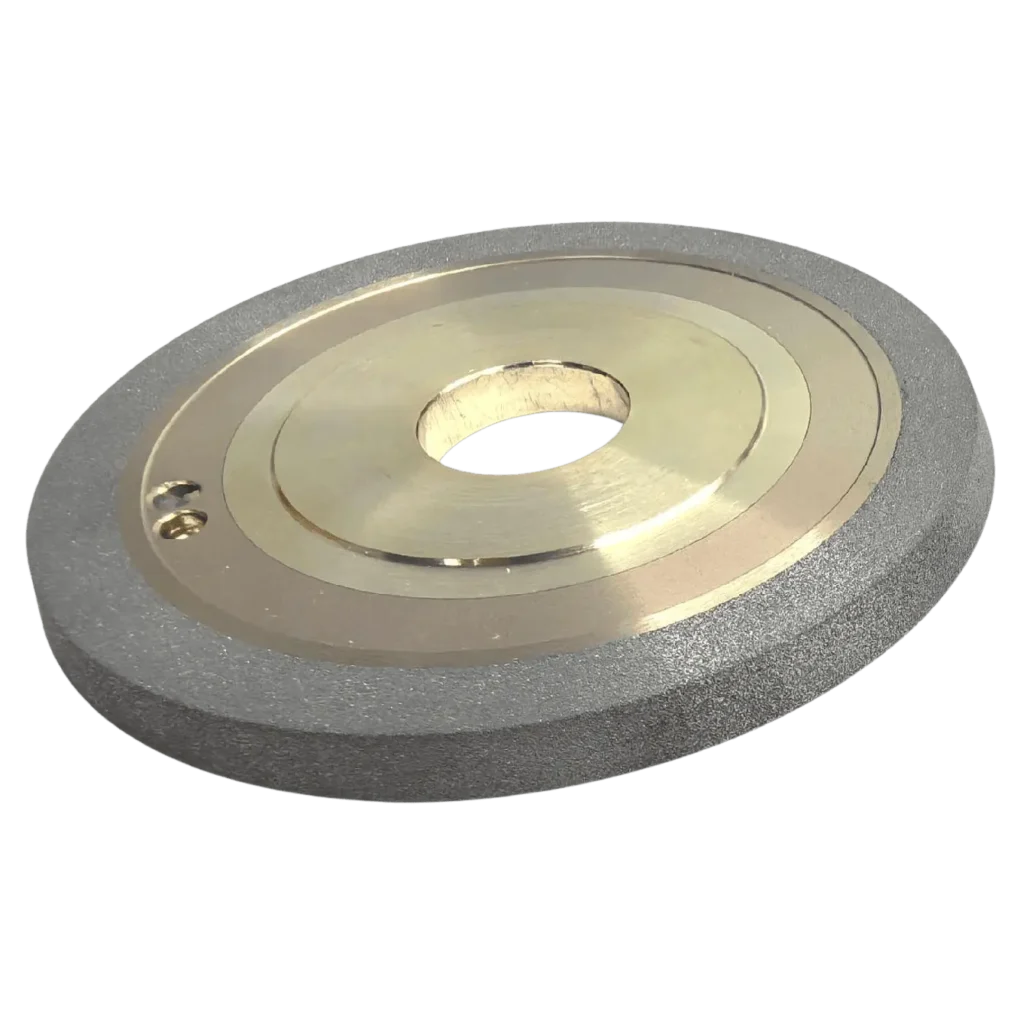

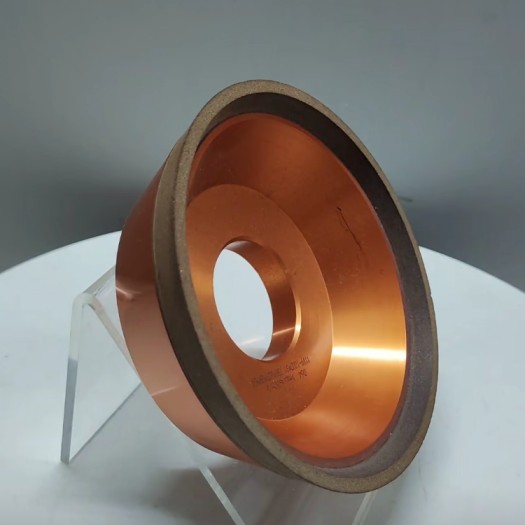

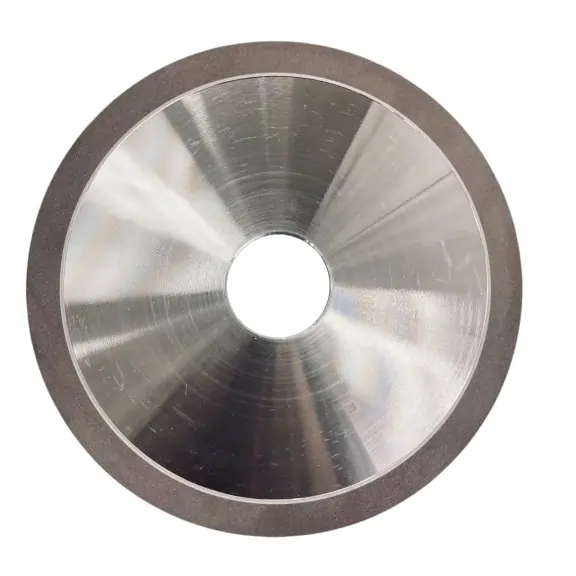

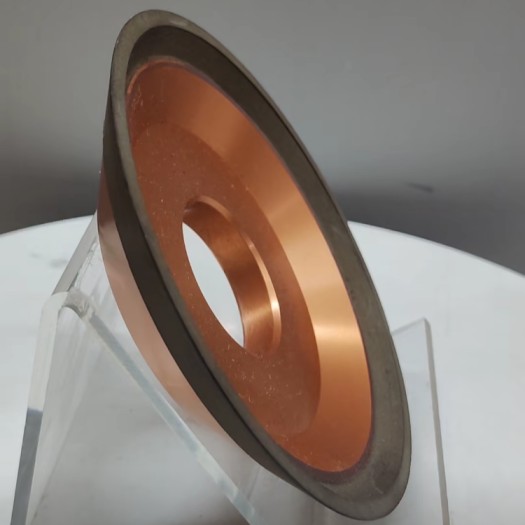

Diamond grinding wheels for carbide inserts and ceramic inserts

Vitrified diamond grinding wheel for inserts

Resin bond diamond grinding wheel for insert cutters

Double-disc Grinding Wheels for inserts tools

Benefits: Precise edge geometry, reduced wear, and improved cutting performance.

Gear Cutter Grinding

Applications: Grinding and sharpening gear cutters for gear manufacturing.

Solutions:

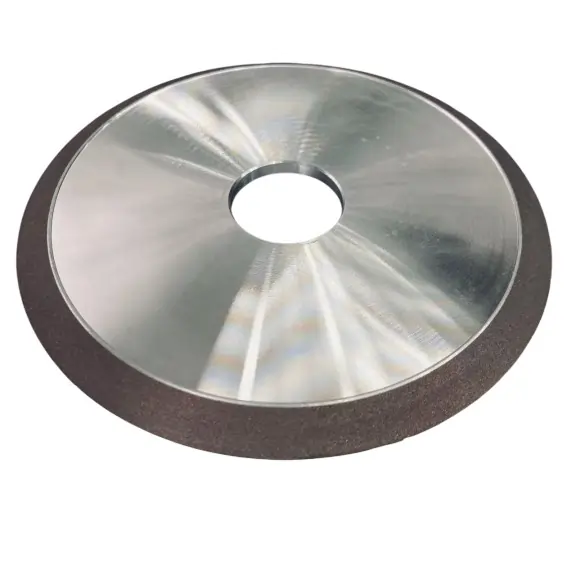

Diamond and CBN grinding wheels for precise tooth profiling.

Vitrified CBN Grinding Wheel for cutter profiling and sharpening

Custom bond types for HSS and carbide cutters.

Benefits: Accurate tooth geometry, smooth finishes, and extended tool life.

Custom Tool Grinding

Applications: Grinding and finishing custom CNC tools for specialized applications.

Solutions:

Diamond and CBN grinding wheels for unique geometries.

Custom bond types for specific materials and requirements.

Benefits: Tailored solutions for complex tool designs and materials.

Why Choose Cast Grind Solutions for CNC Tool and Cutter Grinding?

Precision Tools

Achieve micron-level accuracy for critical CNC tools

Material Expertise

Solutions for HSS, carbide, ceramics, and coated tools

Customization

Tailored abrasives for unique geometries and requirements

Global Expertise

Trusted by leading CNC tool manufacturers worldwide