Precision Cutting, Grinding, and Polishing Solutions

Engineered for Excellence in Every Industry

Home>Applications>Ceramic and Composite Materials

Ceramic and Composite Materials

The ceramic and composite materials industry demands precision, durability, and versatility to process advanced materials like silicon carbide, alumina, zirconia, and fiber-reinforced composites. These materials are widely used in industries such as aerospace, automotive, electronics, and medical devices due to their exceptional strength, thermal stability, and wear resistance. At Cast Grind Solutions, we provide advanced diamond and CBN abrasive tools designed to meet the rigorous demands of this industry.

Our solutions are engineered for precision grinding, cutting, and polishing of ceramics and composites, ensuring superior results in both manufacturing and finishing applications. Whether you’re producing cutting-edge components or restoring worn parts, our tools deliver the accuracy and performance needed to optimize your workflows.

Key Applications in Ceramic and Composite Materials

Precision Grinding of Ceramic Components and Advanced Composites

Applications: Grinding of silicon carbide, alumina, and zirconia components for electronics, aerospace, and medical devices.

Solutions:

Diamond grinding wheels for rough and fine grinding.

Electroplated diamond grinding wheels

Resin bond diamond grinding wheels

Metal bond diamond grinding wheels

Diamond grinding heads in various shapes

Custom bond types for specific ceramic properties.

Benefits: Tight tolerances, superior surface quality, and reduced subsurface damage.

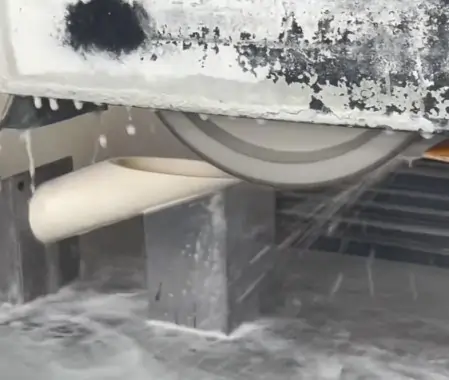

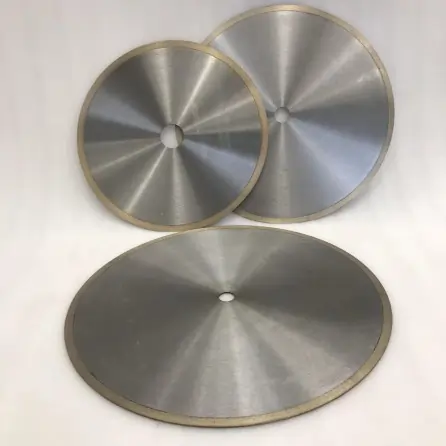

Ceramic and Composite Material Cutting

Applications: Cutting fiber-reinforced composites for aerospace and automotive components.

Solutions:

Diamond cutting wheels for clean, precise cuts.

Diamond band saws for intricate shapes and curves.

Diamond wire saws for ceramic and composite slicing and clean cut off

Benefits: Minimal delamination, high cutting speeds, and consistent edge quality.

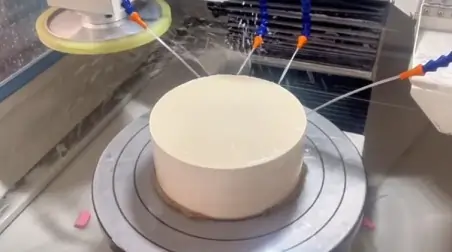

Surface Finishing of Ceramics

Applications: Polishing and finishing of ceramic substrates, insulators, and wear-resistant parts.

Solutions:

Diamond lapping film for ultra-smooth surfaces.

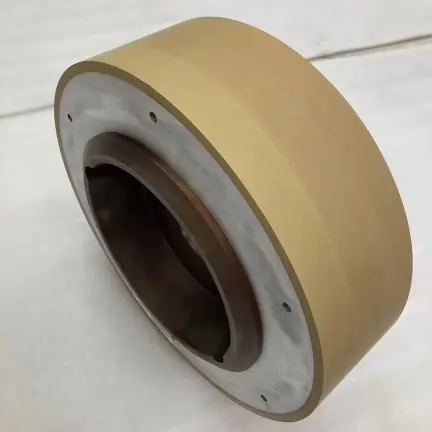

PVA polishing wheels for high-gloss finishes.

Rubber polishing wheel

Diamond finishing fluid

Diamond lapping paste

Benefits: Enhanced surface quality, reduced friction, and improved performance.

Grinding of Advanced Composites

Applications: Grinding carbon fiber-reinforced polymers (CFRP) and glass fiber-reinforced polymers (GFRP).

Solutions:

Diamond grinding wheels for precision shaping.

Abrasive brushes for deburring and edge finishing.

Benefits: High material removal rates, reduced tool wear, and consistent results.

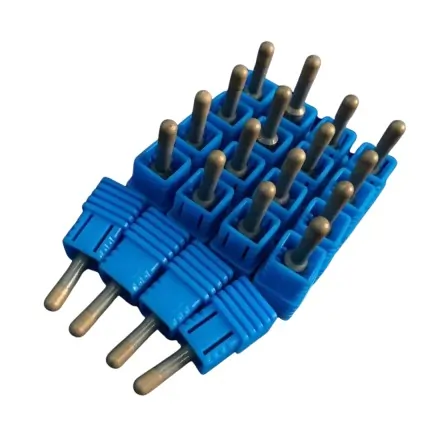

Ceramic Drilling and Core Drilling

Applications: Precision drilling and core drilling of ceramic materials for electronics, aerospace, medical devices, and industrial components.

Solutions:

Diamond Core Drill Bits: For clean, precise holes in hard ceramics like silicon carbide, alumina, and zirconia.

Diamond-Coated Drills: For high-speed drilling of small-diameter holes in ceramic substrates.

Metal bond diamond drills: offering high precision and much more durable hole drilling in ceramics

Why Choose Cast Grind Solutions for Ceramic and Composite Materials?

Precision Tools

Achieve micron-level accuracy for critical components

Material Expertise

Solutions for silicon carbide, alumina, zirconia, and composites

Customization

Tailored abrasives for unique geometries and requirements

Global Expertise

Trusted by leading manufacturers worldwide