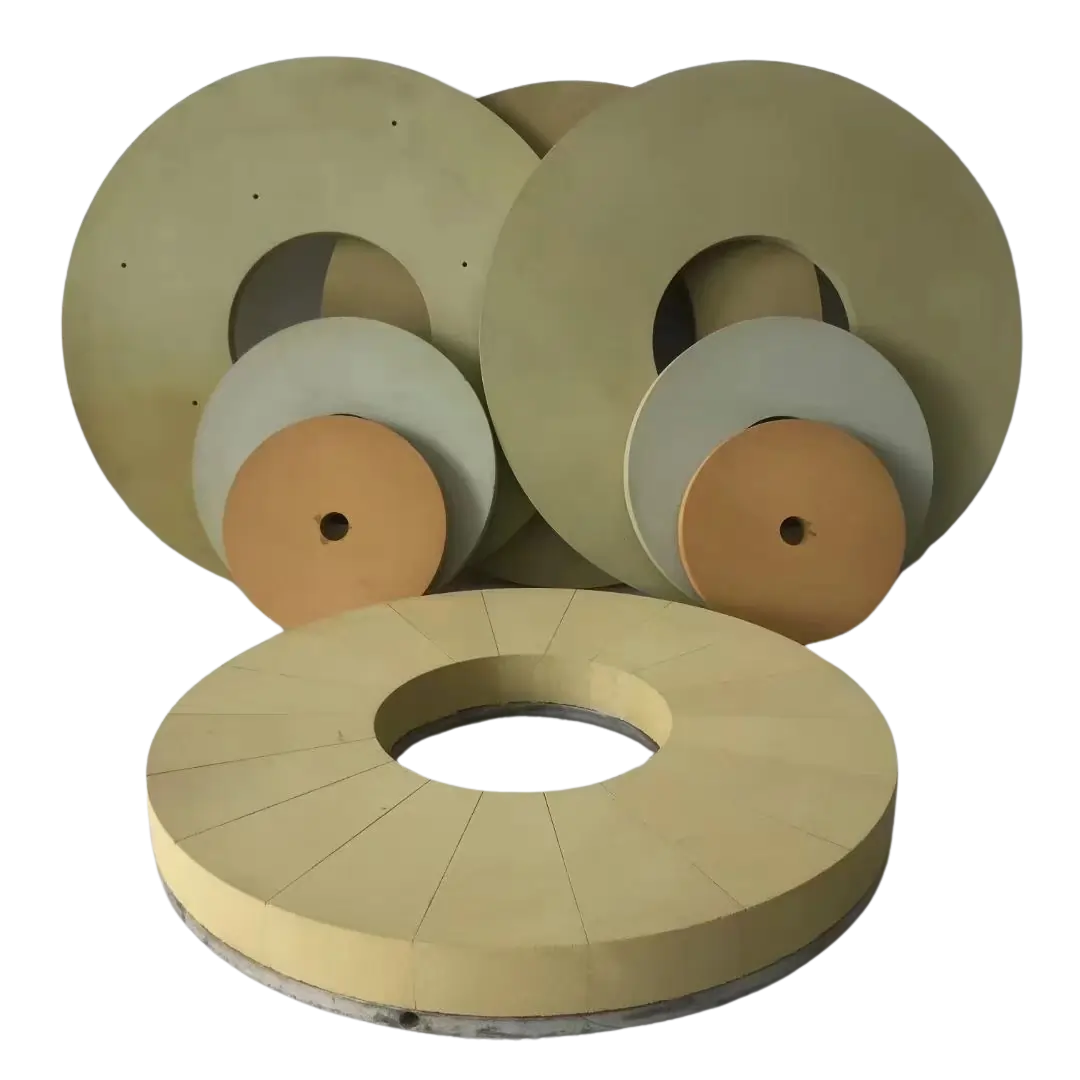

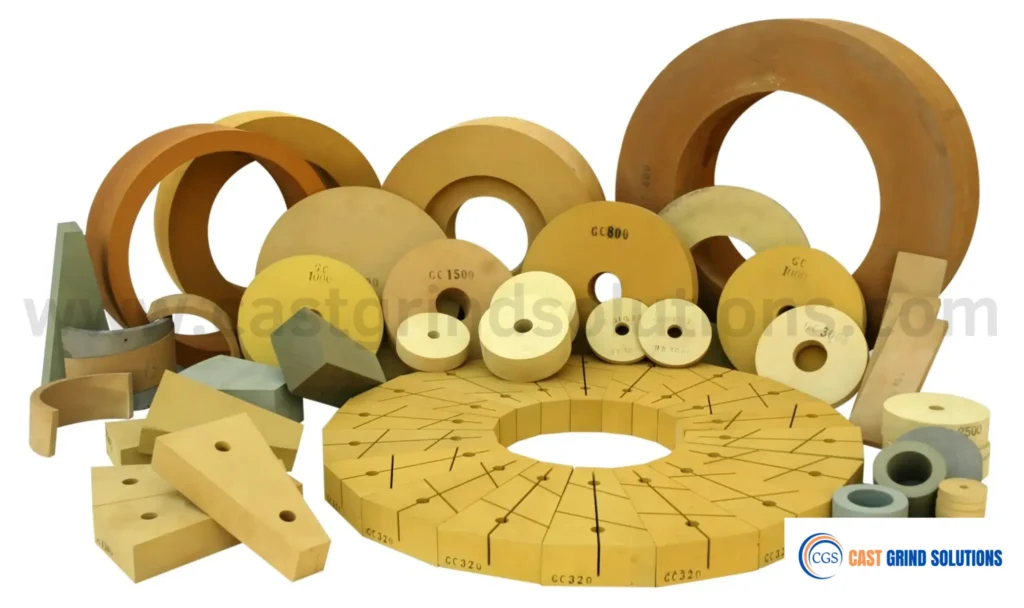

PVA Polishing Wheels

High Porosity: Reduces grinding heat, prevents burns

Elasticity: Provides strong polishing ability

Clog-Resistance: Effective on complex shapes

Particularly suitable for grinding and polishing soft metals, like stainless steel, copper, aluminum, titanium etc.

Description

PVA grinding wheels utilize polyvinyl alcohol formaldehyde compound as their binding agent. These grinding wheels are made by casting polyvinyl alcohol formaldehyde hard elastomer structures as a carrier for polishing abrasives. The abrasive material is typically from the aluminum oxide series or silicon carbide series. Also known as “sponge grinding wheels,” PVA wheels possess a sponge-like, elastic structure.

PVA spongy wheels are particularly suitable for grinding and polishing soft metal materials prone to burn injuries and clogging from grinding heat, including stainless steel, copper, aluminum, and other soft metals. They are also suitable for non-metallic materials such as stone, glass, wood, rubber, plastic, leather, and resin products.

PVA Polishing Wheel Advantages:

High Porosity: The sponge-like structure contains abundant micro pores which effectively reduce grinding heat and prevent workpiece burns.

Elastic and Strong Polishing Ability: The elasticity of the wheel provides a strong polishing capacity.

Clog-resistance: Ideal for polishing various metals and non-metals, especially stainless steel, copper alloys, and complex-shaped parts. PVA grinding wheels replace cloth wheels and adhesive wheels to improve polishing efficiency.

PVA grinding wheels can be used for dry grinding, wet grinding, or oil grinding. The formulations of PVA wheels vary based on the type of grinding:

Dry Grinding PVA Wheels:

The soft binder leaves no deep scratches on the surface, resulting in a smooth finish similar to #400 adhesive wheel or cloth wheel when using #150 sponge grinding wheel.

Constructed with special synthetic resin, PVA sponge wheels enhance wear resistance and grinding power, allowing for the quick removal of debris and the prevention of clogging and overheating, suitable for long-term grinding work.

PVA Wet Grinding Wheels:

Water-resistance PVA wheels exhibit excellent elasticity, enabling them to grind and polish both metal and non-metal materials, with extensive applications. They facilitate automation in polishing operations and provide new solutions for grinding and polishing soft metals and cylindrical metal materials in centerless finish grinding.

Technical Specifications

Common Specifications for PVA Grinding Wheels

Flat Grinding PVA Wheel Specifications

Our PVA wheels for flat grinding come in standard sizes to meet various industrial requirements. These wheels excel in grinding and polishing flat surfaces of metals, stainless steel, cast iron, and non-metal materials.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 150 | 16-100 | 25 | 46#-3000# | 20-30 | GC | both |

| 180 | 16-100 | 32 | 46#-3000# | 20-30 | Silicon carbide | both |

| 222 | 16-100 | 32 | 46#-3000# | 20-30 | Silicon carbide | both |

| 250 | 25-75 | 75 | 46#-3000# | 20-30 | Silicon carbide | both |

| 300 | 25-100 | 127 | 46#-3000# | 20-30 | Silicon carbide | both |

| 350 | 25-125 | 127,203 | 46#-3000# | 20-30 | Silicon carbide | both |

| 400 | 40-75 | 127,203 | 46#-3000# | 20-30 | Silicon carbide | both |

| 450 | 75-125 | 305 | 46#-3000# | 20-30 | Silicon carbide | both |

| 500 | 50-75 | 305 | 46#-3000# | 20-30 | Silicon carbide | both |

| 600 | 50-75 | 305 | 46#-3000# | 20-30 | Silicon carbide | both |

External Cylindrical Grinding PVA Wheel Specifications

We offer PVA wheels for external cylindrical grinding, available in a variety of standard sizes. These wheels provide excellent surface finish and precision for cylindrical surfaces of metals, including stainless steel and cast iron.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 250 | 20 | 75 | 46#-3000# | 20-30 | GC | both |

| 300 | 40,50,100 | 127 | 46#-3000# | 20-30 | Silicon carbide | both |

| 350 | 125 | 127 | 46#-3000# | 20-30 | Silicon carbide | both |

| 400 | 50,150 | 203 | 46#-3000# | 20-30 | Silicon carbide | both |

| 450 | 50 | 203 | 46#-3000# | 20-30 | Silicon carbide | both |

| 500 | 50,75,100 | 203,305 | 46#-3000# | 20-30 | Silicon carbide | both |

| 600 | 63,75 | 305 | 46#-3000# | 20-30 | Silicon carbide | both |

Centerless Grinding PVA Wheel Specifications

Our PVA wheels for centerless grinding are designed to fit a wide range of centerless grinding machines. Standard sizes are available, ensuring high efficiency and surface quality for various metals and alloys.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 125 | 50 | 50 | 46#-2000# | 20-30 | GC | both |

| 200 | 50 | 50 | 46#-2000# | 20-30 | Silicon carbide | both |

| 250 | 100 | 75 | 46#-2000# | 20-30 | Silicon carbide | both |

| 300 | 100,125,150 | 120,127 | 46#-2000# | 20-30 | Silicon carbide | both |

| 350 | 125,150 | 127 | 46#-2000# | 20-30 | Silicon carbide | both |

| 400 | 100,125,150,200 | 203 | 46#-2000# | 20-30 | Silicon carbide | both |

| 450 | 150,200 | 228.6,203 | 46#-2000# | 20-30 | Silicon carbide | both |

| 500 | 100,125,150,200 | 305 | 46#-2000# | 20-30 | Silicon carbide | both |

| 600 | 150,200 | 305 | 46#-2000# | 20-30 | Silicon carbide | both |

PVA Mounted Points Specifications

PVA mounted points are small cylindrical or conical grinding tools connected to a metal shank. These tools are designed for use with electric or pneumatic grinding equipment, allowing for precise polishing in difficult-to-reach areas like burrs, inner holes, corners, depressions, and other intricate surfaces of metals, stainless steel, cast iron, and non-metal materials. PVA mounted points are perfect for deburring, weld spots, burr removal, edge polishing, and grinding internal corners and pipes of various metal materials.

| Size(mm) | Shank Size(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 20*25 | 3,6 | 75 | 80#-1000# | 20-30 | GC | dry |

| 25*25 | 3,6 | 127 | 80#-1000# | 20-30 | Silicon carbide | dry |

| 30*25 | 3,6 | 127 | 80#-1000# | 20-30 | Silicon carbide | dry |

| 30*30 | 3,6 | 203 | 80#-1000# | 20-30 | Silicon carbide | dry |

We offer customized PVA grinding wheel services. Please provide your usage requirements, and we will deliver the best grinding wheel solution tailored to your needs. Our PVA polishing wheels can often replace UB grinding wheels, providing a more cost-effective grinding solution.

Features

Selection of PVA Grinding Wheels:

Specifications:

To achieve desired grinding and polishing results, selecting the correct wheel parameters is crucial.

PVA Polishing Wheel Abrasive Types: white aluminum oxide, silicon carbide;

Abrasive Grain Size: 46-3000#

PAV Wheel Hardness: S (Soft), MS (Medium Soft), M (Medium), MH (Medium Hard), H (Hard)

Structure: 1 (Dense) to 5 (Sparse)

Water Resistance: WP (Water-resistant), NWP (Non-water-resistant)

PVA Polishing Wheel Dimensions (mm): Outer Diameter*Thickness*Inner Diameter

PVA Grinding Wheel Shapes:

PVA wheels can be made into various shapes, such as PVA Point Polishing Wheel, PVA grinding blocks,PVA Edge Polishing pads,PVA centerless grinding wheel, flat wheels, and OD(outside diameter) grinding wheels.

PVA Grinding Wheel Operational Speed:

The line speed should be 35m/s, with an appropriate speed between 25-35m/s based on the specific application.

Grinding Pressure:

Grinding pressure is a critical factor for optimal performance. Adjust pressure according to wheel type, workpiece material, and grinding method. Typically, finishing: 1-2kg/cm², rough grinding: 3-5kg/cm².

Coolants:

While PVA dry grinding wheels do not generally require coolants, the following conditions necessitate coolant use:

- Achieving exceptional surface smoothness;

- Grinding materials that generate high heat and are prone to burns;

- Prolonged, continuous automatic grinding.

For dry grinding wheels (NWP): Use kerosene, light oil, but not water as coolants.

For water-resistant wheels (WP): Water can be used as a coolant.

Wheel Dressing:

Diamond dressers, ceramic grinding wheels, or resin grinding wheels should be used to dress PVA grinding wheels before use.

Application

Saw Blade Polishing PVA Grinding Wheel

Our specially developed PVA grinding wheels for saw blade polishing are widely used for surface polishing and grinding of woodworking saw blades, carbide saw blades, and diamond saw blades. They can replace sanding wheels and belts, achieving smooth and fine laser three-dimensional light surfaces (laser patterns).

Wet Grinding Saw Blade PVA Finishing Wheel: Excellent water absorption, prevents burning the blade. Specially suitable for woodworking saw blades made from 65Mn spring steel, carbon tool steel, and alloy tool steel, carbide saw blades, and diamond saw blades.

Dry Grinding Saw Blade PVA Grinding Wheel: Ideal for ultra-thin saw blades with thickness less than 1mm made of high-speed steel. Prevents heat build-up and deformation, offering superior polishing results.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 150 | 15-40 | 20 | 46#-240# | 20-30 | GC | both |

| 200 | 15-40 | 25 | 46#-240# | 20-30 | Silicon carbide | both |

| 250 | 20-40 | 32 | 46#-240# | 20-30 | Silicon carbide | both |

| 300 | 25-40 | 50 | 46#-240# | 20-30 | Silicon carbide | both |

Stainless Steel Polishing PVA Grinding Wheel

With a sponge-like structure, our PVA polishing wheels are soft, slightly elastic, and have excellent heat dissipation during grinding and polishing. They are specially designed for stainless steel, sheets, medical instruments, food machinery, industrial tools, stainless steel knives, cutlery, and kitchen utensils. After polishing, the product is free of spots and scratches, with a beautiful finish.

120#-180#-400# Stainless Steel PVA Polishing Wheels: Achieve a surface smoothness of Ra0.1-0.05 on stainless steel pipes.

800#-1000# Stainless Steel PVA Polishing Wheels: Achieve a surface smoothness of Ra0.03-0.01 on stainless steel pipes, delivering excellent performance.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 150 | 8-100 | 16 | 46#-3000# | 20-30 | GC | dry |

| 180 | 8-100 | 20 | 46#-3000# | 20-30 | Silicon carbide | dry |

| 200 | 8-100 | 25 | 46#-3000# | 20-30 | Silicon carbide | dry |

| 250 | 8-100 | 32 | 46#-3000# | 20-30 | Silicon carbide | dry |

| 300 | 8-100 | 50 | 46#-3000# | 20-30 | Silicon carbide | dry |

| 350 | 8-100 | 76.2 | 46#-3000# | 20-30 | Silicon carbide | dry |

| 400 | 8-100 | 127 | 46#-3000# | 20-30 | Silicon carbide | dry |

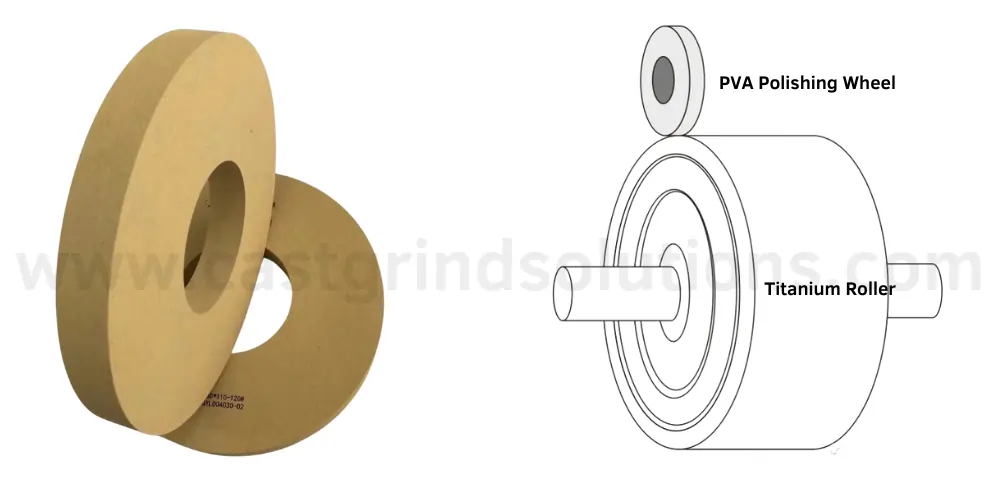

Titanium Roller Polishing PVA Grinding Wheel

Our titanium roller (cathode roller) polishing wheels are designed for electrolytic copper foil manufacturers to quickly remove oxidation film from the roller surface, restoring a smooth, silver-white titanium oxide crystal layer, thereby improving copper foil appearance quality.

Made from green silicon carbide abrasive and flexible PVA bond, these PVA wheels move uniformly along the roller axis, performing wet grinding for higher efficiency, stable quality, and excellent polishing results.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 250 | 30,50 | 76.2 | 60#-1200# | 20-30 | GC | wet |

| 300 | 30,40,50,100 | 100 | 60#-1200# | 20-30 | Silicon carbide | wet |

| 330 | 30,40,50 | 127 | 60#-1200# | 20-30 | Silicon carbide | wet |

| 350 | 40,50 | 203 | 60#-1200# | 20-30 | Silicon carbide | wet |

| 600 | 50,75 | 305 | 60#-1200# | 20-30 | Silicon carbide | wet |

Copper Roller Polishing PVA Grinding Wheel

Our PVA grinding wheels for copper rollers are specifically designed for coarse grinding, fine grinding, and polishing of copper rollers in large engraving printers, packaging machinery corrugating machines, and copper plate rollers. The PVA finishing wheel structure is loose, leaving no vibration marks on the rollers. It achieves high precision and surface smoothness of Ra0.05.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 200 | 25-100 | 32,50 | 80#-3000# | 20-30 | GC | wet |

| 250 | 32-100 | 76.2 | 80#-3000# | 20-30 | Silicon carbide | wet |

| 300 | 32-100 | 127 | 80#-3000# | 20-30 | Silicon carbide | wet |

| 350 | 40,50,75 | 127 | 80#-3000# | 20-30 | Silicon carbide | wet |

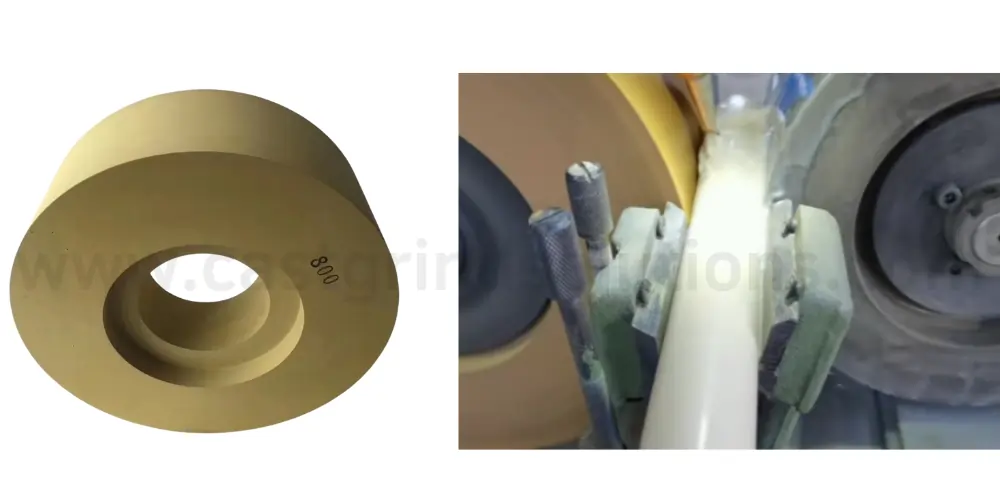

Grinding Machine PVA Polishing Wheels

Cast Grind Solutions provides PVA wheels compatible with various centerless grinding machines, helping customers design and optimize grinding solutions to save costs. We offer PVA wheels for models such as M1010, M1025, M1020, M1025K, M1040, M1050, M1075, M1080, M1081, M1082, M1083, and GJ1050. Custom shapes and sizes are available per customer requirements.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 125 | 50 | 50 | 46#-2000# | 20-30 | GC | both |

| 200 | 50 | 50 | 46#-2000# | 20-30 | Silicon carbide | both |

| 250 | 100 | 75 | 46#-2000# | 20-30 | Silicon carbide | both |

| 300 | 100,125,150 | 120,127 | 46#-2000# | 20-30 | Silicon carbide | both |

| 350 | 125,150 | 127 | 46#-2000# | 20-30 | Silicon carbide | both |

| 400 | 100,125,150,200 | 203 | 46#-2000# | 20-30 | Silicon carbide | both |

| 450 | 150,200 | 228.6,203 | 46#-2000# | 20-30 | Silicon carbide | both |

| 500 | 100,125,150,200 | 305 | 46#-2000# | 20-30 | Silicon carbide | both |

| 600 | 150,200 | 305 | 46#-2000# | 20-30 | Silicon carbide | both |

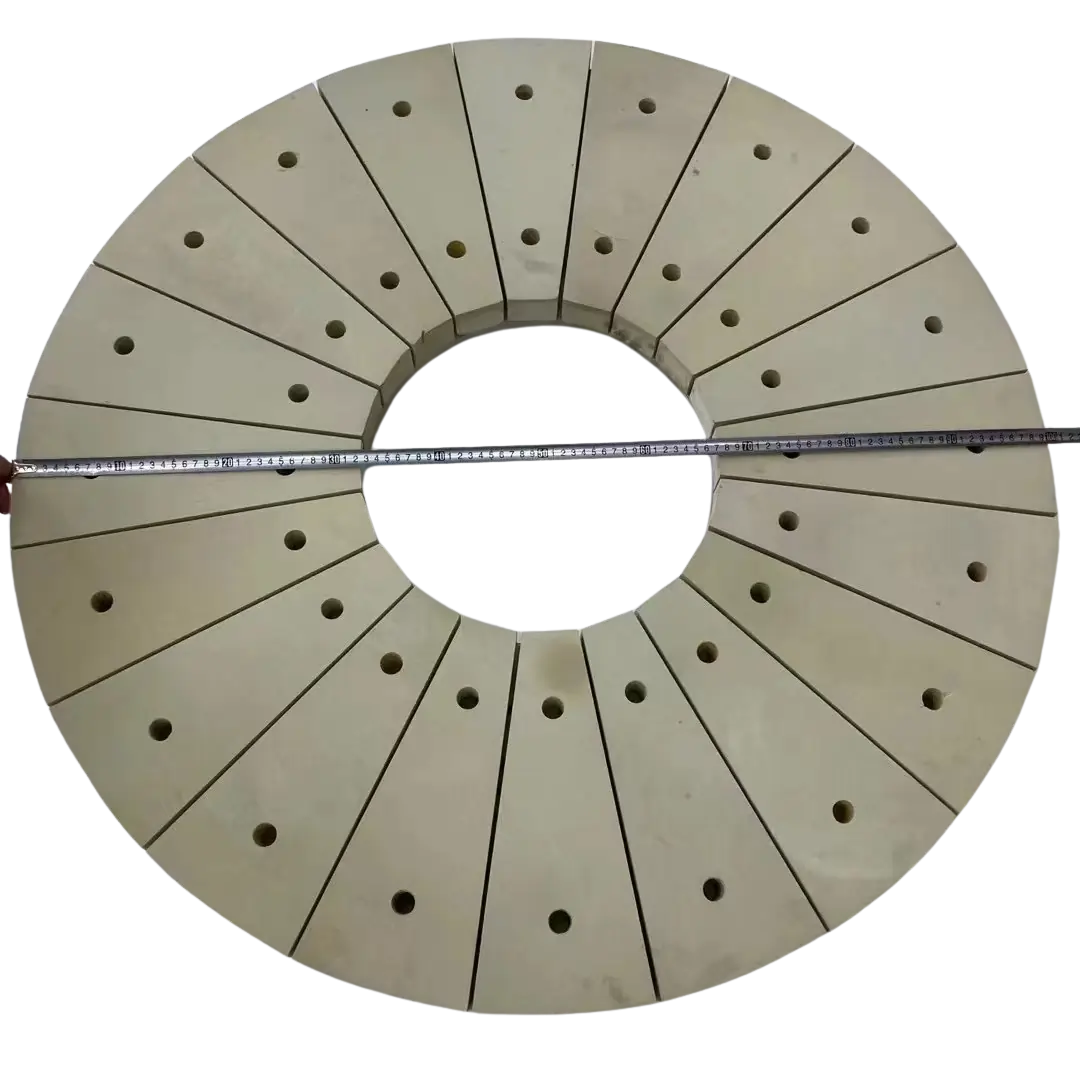

Double-Disc Grinder PVA Grinding Discs

We produce PVA grinding discs for double-disc grinders, ideal for ultra-precision grinding and polishing of soft metal surfaces like aluminum discs in computer drives, SIM cards, watch dials, and electronic components, achieving a mirror effect. Available in segments type or whole piece circular discs, they can be customized to fit various grinder models. We also provide special adhesive for binding the PVA grinding discs.

| PVA Grinding Plate Types | Diameter(mm) | Thickness(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| Circular shape(whole piece of wheel) | 610-650 | 30-60 | 120#-3000# | 20-30 | Silicon carbide | wet |

| Segment(in 18pcs) | 640-650 | 40-60 | 120#-3000# | 20-30 | Silicon carbide | wet |

Non-Metal PVA Polishing Wheels

Our PVA wheels have a special formula for non-metal materials like synthetic resins, optical glass, eyewear lenses, rubber rollers for printing, jewelry, ceramics, and microcrystalline glass. They excel in rough grinding, fine grinding, and polishing, with good porosity and water absorption, ensuring effective debris removal, heat dissipation, and preventing wheel blockage.

| Diameter(mm) | Thickness(mm) | Bore Size(mm) | Grit Size | Speed(m/s) | Abrasive Type | Dry/wet Grinding |

| 80-600 | 10-200 | 16-305 | Rough grinding:60#-240# precision Grinding:400#-800#Polishing:1000#-4000# |

20-30 | Silicon carbide | Both |