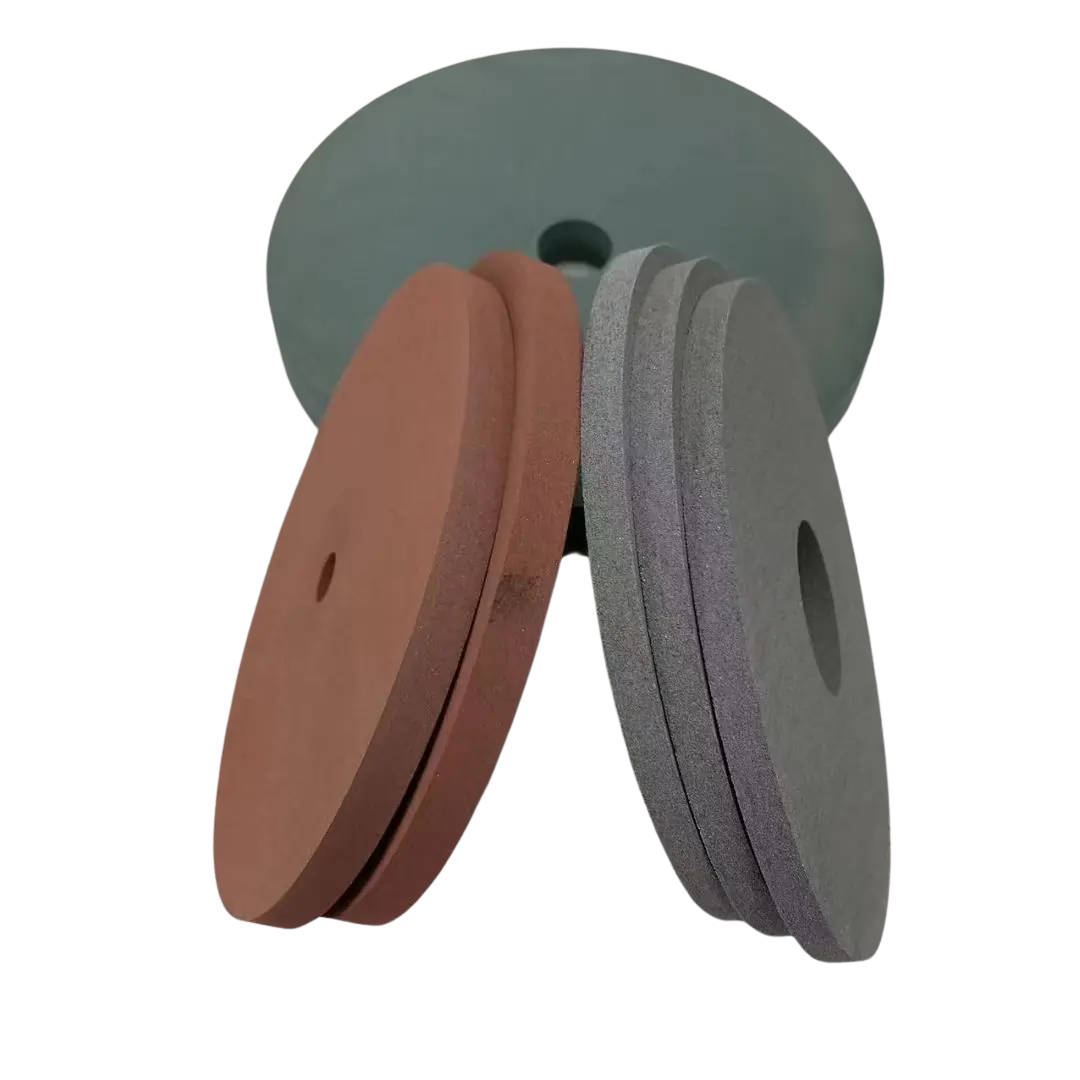

Rubber Polishing Wheels

With high-quality rubber and abrasives material

Provide excellent elasticity and softness, ideal for various shapes and curved surfaces.

Excel in fine grinding and polishing non-ferrous metals and hard alloys, including mirror finishes on copper, aluminum, titanium and stainless steel.

Description

Rubber polishing wheels, also known as rubber elastic buffing wheels, play a crucial role in modern industrial production due to their efficient and versatile nature. Combining the flexibility of rubber with the grinding power of abrasive wheels, these polishing wheels provide an ideal solution for various surface finishing needs. They are particularly useful for fine grinding and polishing tasks on materials such as non-ferrous metals and hard alloys. Applications include mirror-polishing surfaces made from copper, aluminum, stainless steel, and more.

Technical Specifications

Types of Abrasives Used in Rubber Polishing Wheels

Brown Fused Alumina (BFA): Known for its high hardness and wear resistance, brown aluminum is effective in removing rough layers and suitable for both metallic and non-metallic materials.

White Fused Alumina (WFA): Similar to BFA but often preferred for higher precision polishing jobs that require finer finishes.

Silicon Carbide (SiC): Available in green silicon carbide and black silicon carbide abrasives, SiC offers high hardness, wear resistance, and thermal stability, making it ideal for harder materials like carbide and ceramics.

Specifications

Grain Size Range: 46# – 3000#

Hardness Range: 40 – 95 degrees

Color: Primarily brown-black, with variations based on specific requirements.

Density Levels: normal, medium , high; Various grades available for different working conditions.

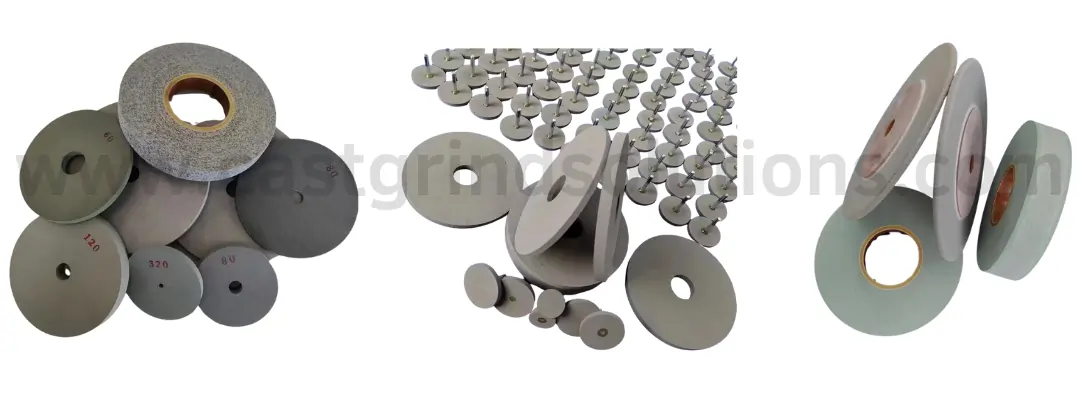

Shapes: Customizable into rubber polishing blocks, mounted point with shank, or specialized polishing wheel shapes for various machines, with options to increase rotational speed by adding core materials.

Features

Rubber polishing wheels, crafted from highly wear-resistant rubber, boast long life spans and resistance to high temperatures. They excel in both metal and non-metal grinding sectors, offering functions like flat surface grinding, contour grinding, deburring, flash removal, chamfering, and polishing. These polishing wheels can handle large amounts of material removal and achieve fine finishes, characterized by fast cutting speeds, high efficiency, excellent surface quality, minimal clogging, no workpiece burn, low noise, reduced vibration, and safe operation environments. Compared to traditional grinding wheels, they can improve productivity by 6-15 times and reduce material consumption by about two-thirds. These advantages have led to widespread adoption across mechanical processing, assembly, tooling, and other fields, replacing traditional sanding, grinding, filing, and polishing methods.

Application

Application Areas

Metal Finishing: Widely used in metalworking industries for surface finishing of various metal products like stainless steel ,aluminum alloys, copper foil. The soft material prevents scratches while improving efficiency.

Glass Finishing: Effective in removing defects and scratches from glass surfaces, producing smoother and clearer glass products.

Other Materials: Suitable for ceramics, plastics, and other materials, making it a versatile polishing toolfor multiple applications.