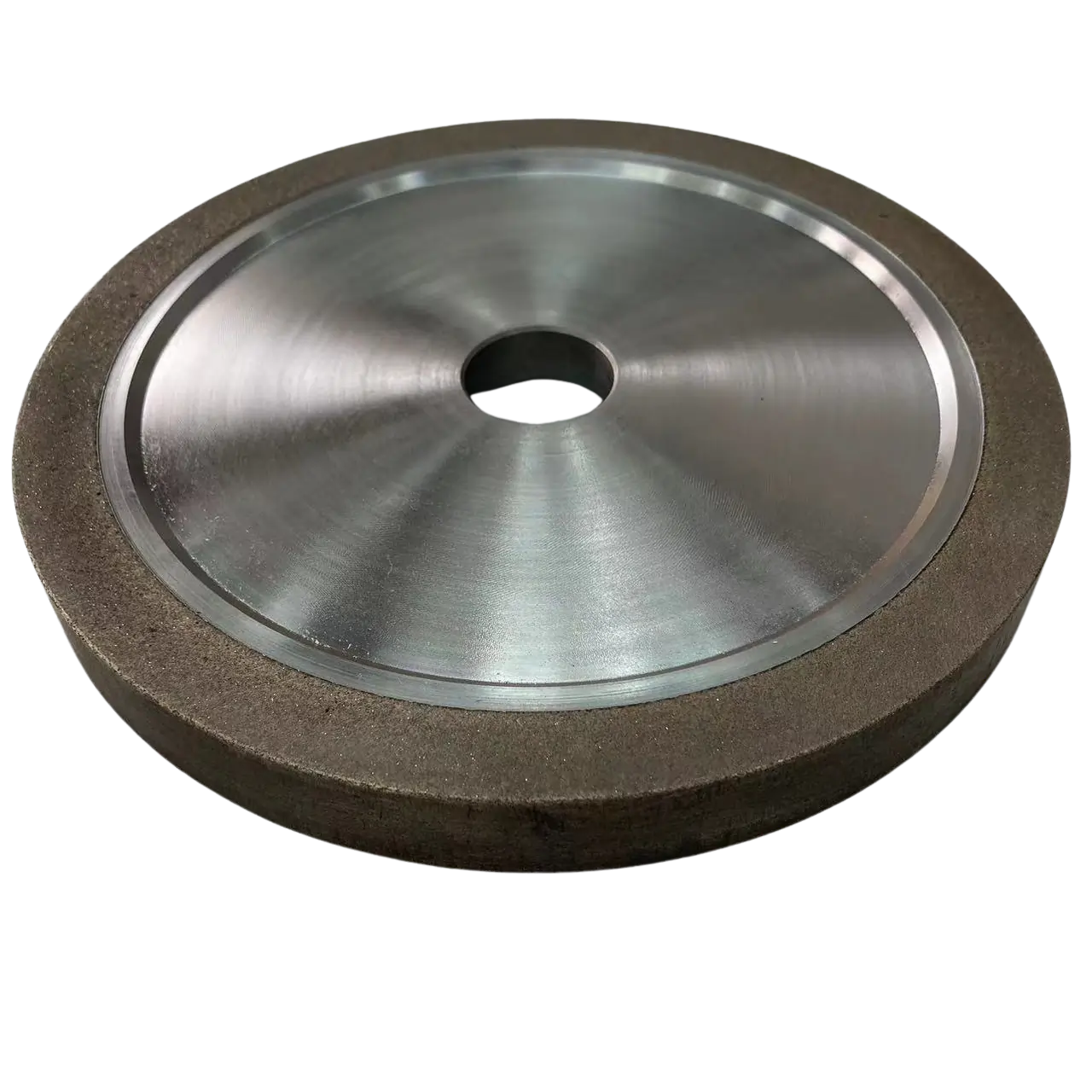

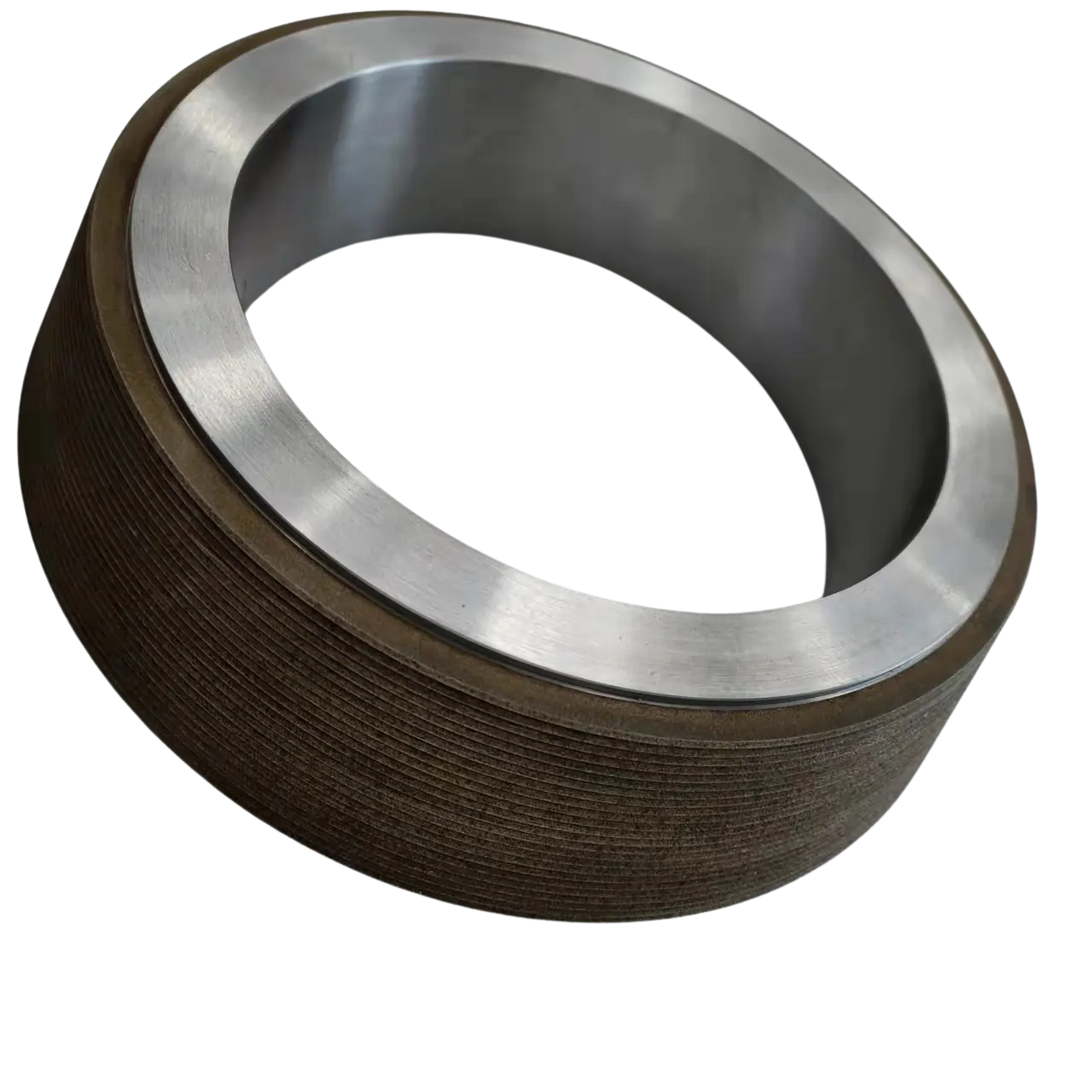

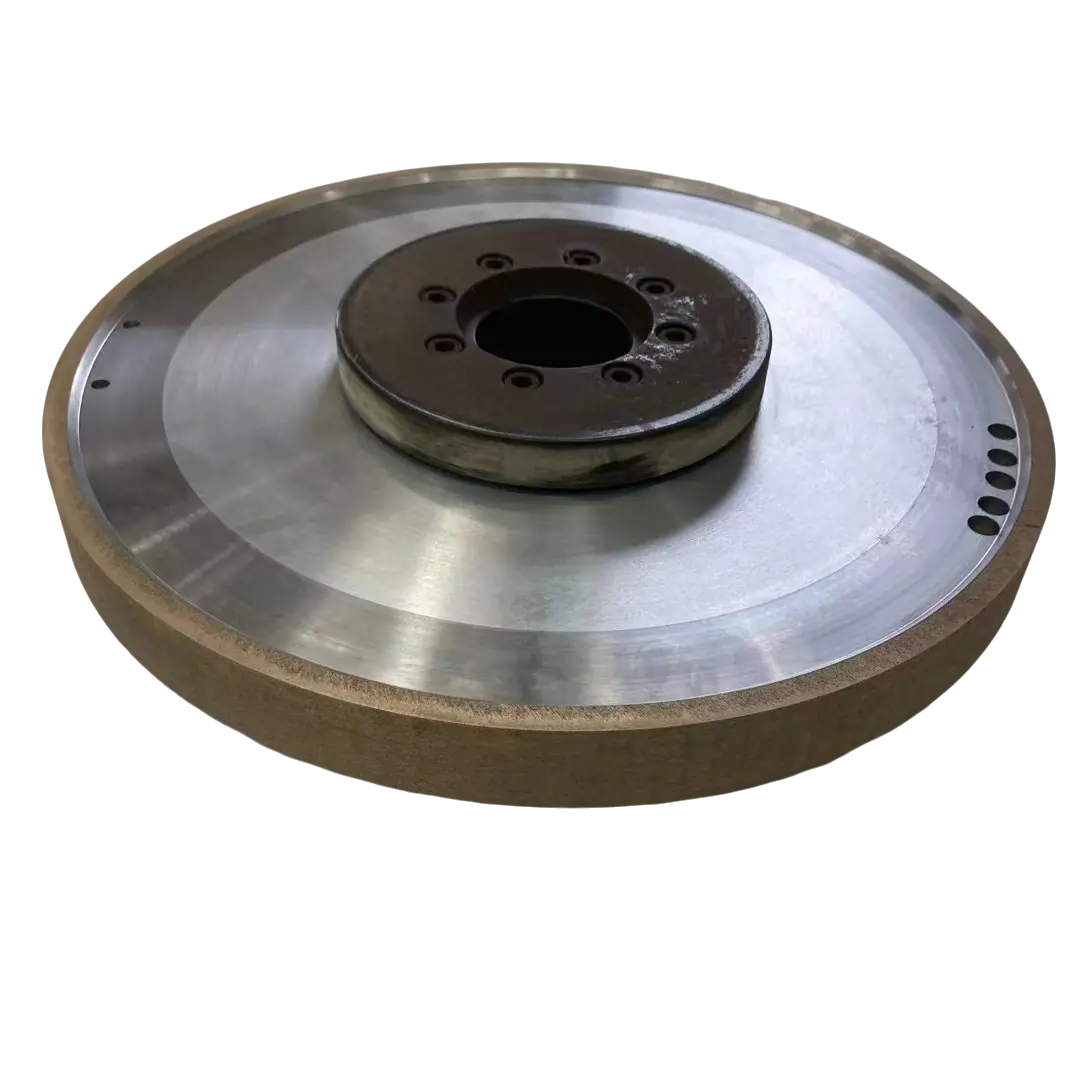

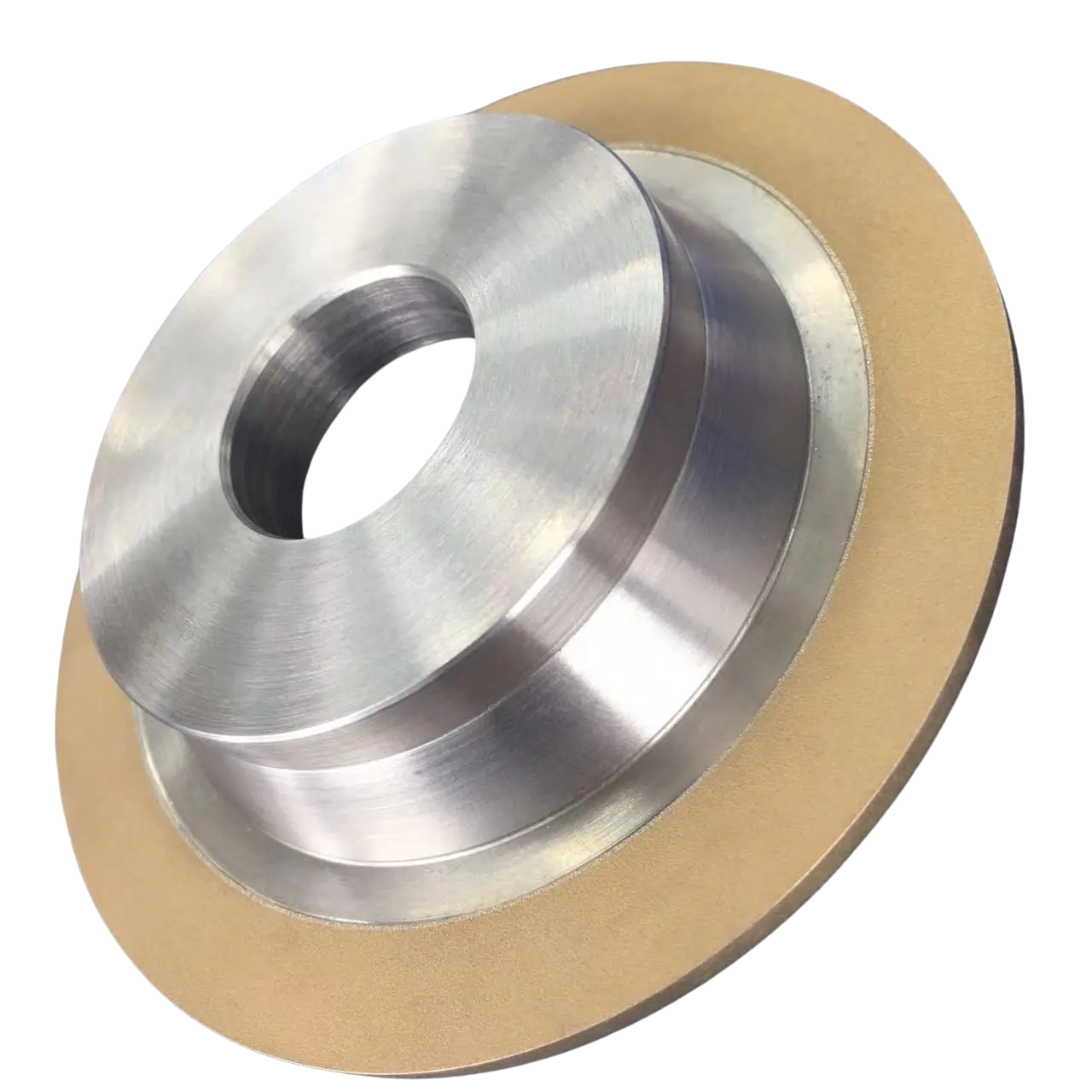

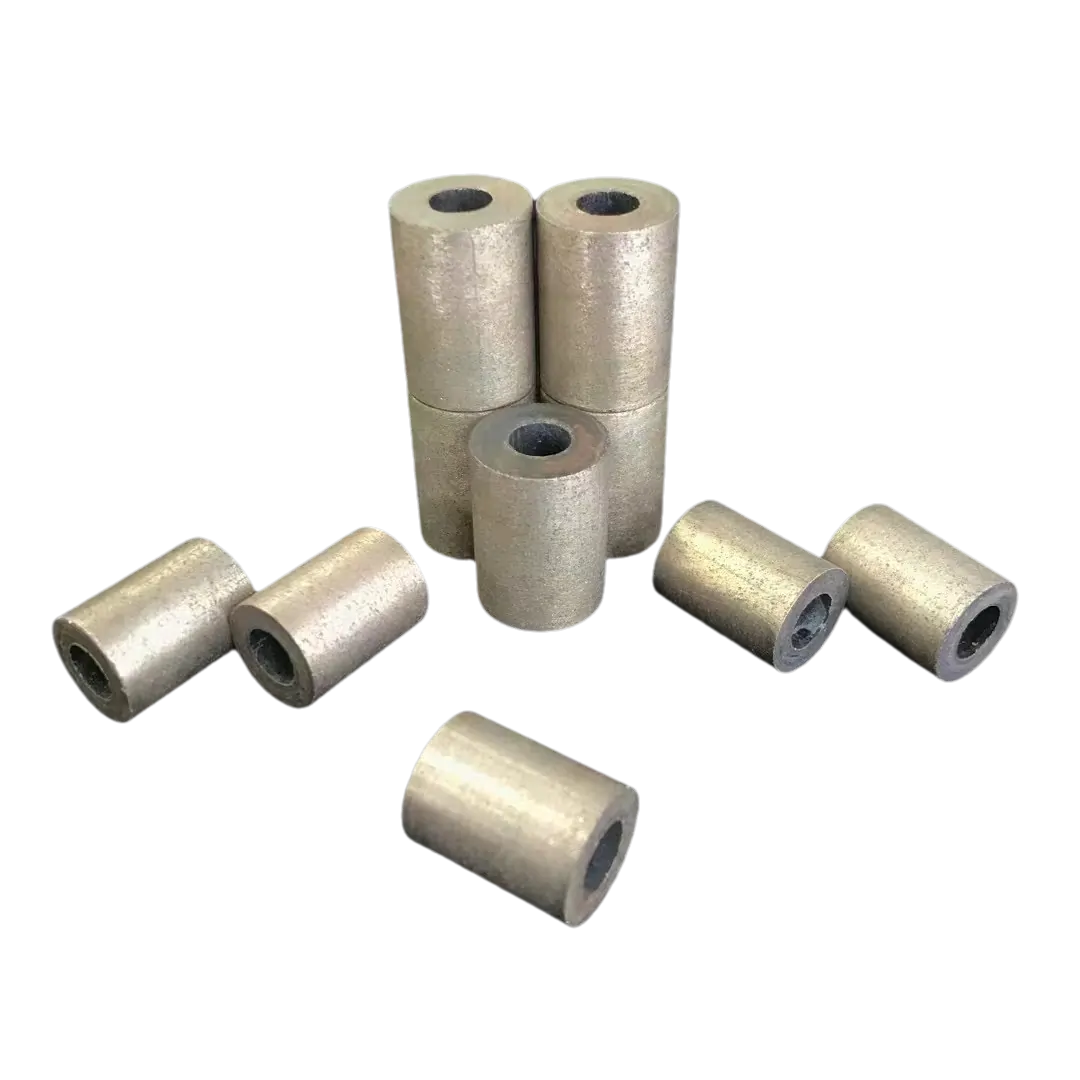

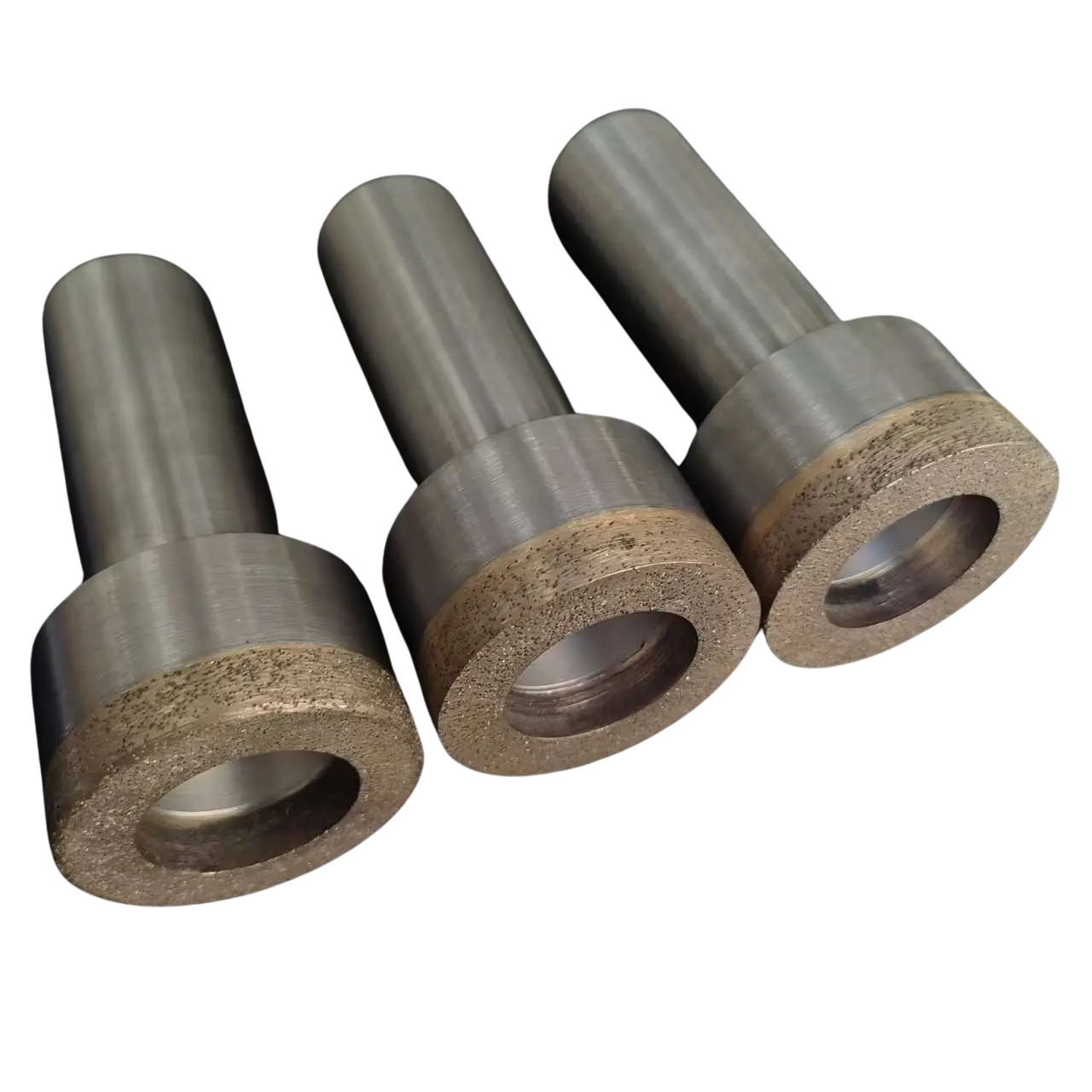

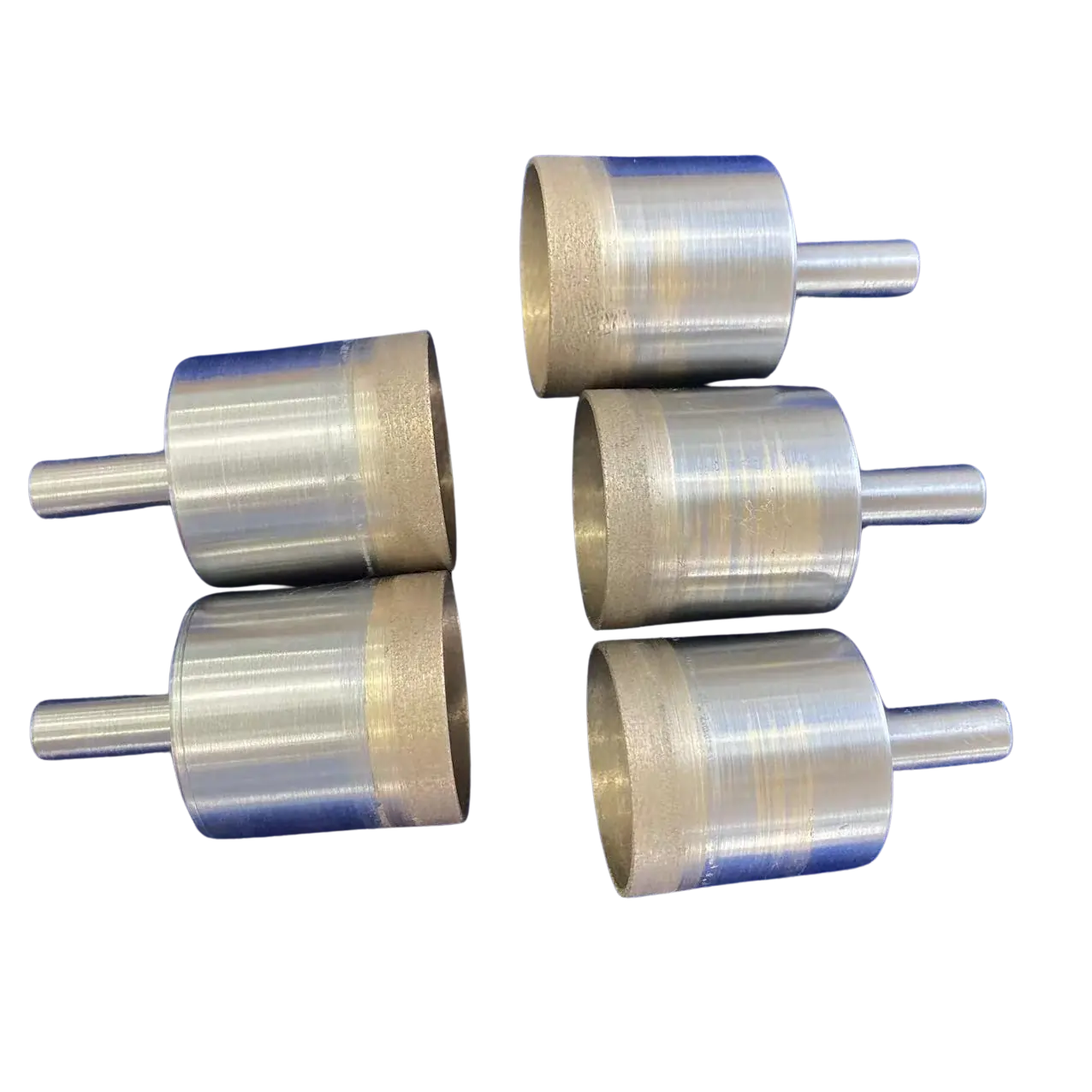

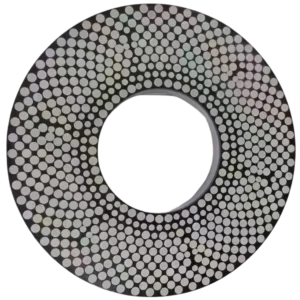

Metal Bond Diamond and CBN Grinding Wheels

Available in metal bond diamond and metal bond CBN

Metal Bond Features:

- Longest life time compared with other bond types

- High wear resistance and superior impact

- High strength idea for heavy-duty grinding tasks

- Excellent thermal conductivity

- Capable of being fabricated into intricate designs with excellent form-holding

- High precision and stability during grinding

Applications: carbide, ceramics, glass, gemstones, and stone.

Description

Bronze Sintered Diamond and CBN Wheels are abrasive tools manufactured by sintering diamond or CBN abrasives with bronze powder under high temperature and machining. These grinding wheels are primarily used for grinding hard and brittle materials such as carbide, ceramics, glass, gemstones, and stone. Key features of bronze sintered diamond and CBN wheels include high bonding strength, excellent formability, high temperature resistance, superior thermal conductivity and wear resistance, and long service life. They can withstand substantial loads.

Types of Metal Bond Diamond and CBN Tools

A wide array of diamond and CBN tools can be crafted using a metal bond matrix. These include:

Diamond grinding wheels for surface smoothing.

Diamond cutoff wheels for slicing, slotting, and grooving.

Diamond core drills and bits for drilling, reaming, and milling.

Diamond router bits, carving points, and forming tools for shaping and molding.

Sophisticated tool shapes can be easily fabricated, with angles and radii precisely ground to meet customer-specific requirements. High precision tolerances can be maintained through precision grinding techniques on tool faces. A diverse range of diamond grit sizes, spanning from 16 mesh size to 10,000 mesh size, can be integrated with diamondor CBN concentrations from 25% to 150% . Additionally, different bond hardnesses, bond matrices, and diamond/CBN crystal types can be tailored to achieve the desired surface finish, cutting speed, tool longevity, and consistency as specified by clients.

Our extensive range of metal bond diamond and CBN wheels ensures effective grinding solutions for diverse industries. Our dedicated team is ready to provide customized solutions tailored to your specific requirements, enhancing your operational efficiency and product quality.

For further inquiries or to discuss your specific grinding needs, please visit our website or contact us directly.

Technical Specifications

Abrasive Type: synthetic diamond, synthetic coated diamond, synthetic CBN, synthetic coated CBN(cubic boron nitride)

Bond Type: metal bond(sintered) ;based on your special application. Offering suitable formula

Diamond Grit Sizes: 16 grit to 10000 grit

CBN Grit Size: 45 grit to 5000 grit

Diamond/CBN Concentration: low , medium , high, 25%, 50%,75% 100% 125%, 150%

Metal Bond Hardness: hard, medium, soft, super soft

Diameter Available : 1.8mm up to 900mm, for special size, we can make mould for it and meet with your specification

Thicknesses Available : 0.03mm up to 200mm, under 1mm thickness are metal bond diamond /cbn cutting wheel

Arbor Size(inside diameter):for any bore size, normal size are : 1/8inch, 1/4inch,3/8inch, 1/2inch, 5/8inch, 3/4inch, 1.25inch, 1.57inch, 2.75inch, 3.5inch ,3.9inch, 4.9inch, 5inch, 12inch

Diamond/CBN Depth: any depth;such as 5mm, 10mm, 15mm, 20mm, 40mm or from OD to ID fully impregnated with diamond/CBN

Edge Type: continuous rim or slotted

Core Type: steel matrix, aluminum matrix

Tolerances: based on drawing tolerance;

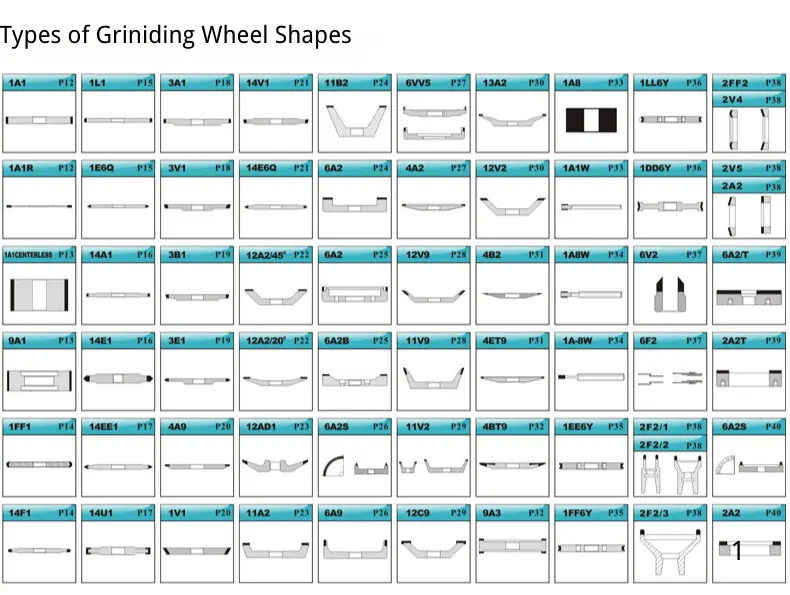

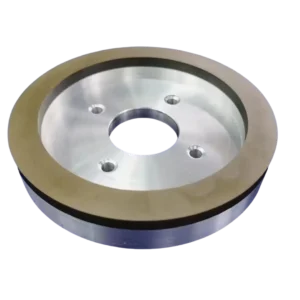

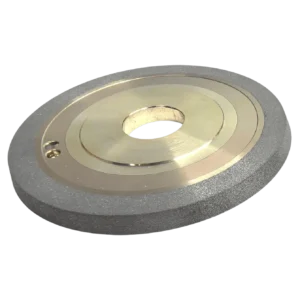

Grinding Wheel Shapes: 1A1,1A1R, 1L1, 1V1, 3A1,1E1, 4BT9, 6A2, 6A9, 14V1, 13A2, 9A1, 14E1, 1FF1, 3V1, 11B2, 6VV5, 12V2, 4A2, 1E1,1M1, 1N1, 1A8, 1E8, 1zm8, 1N8, 1V8 1A1, 14U1, 6A2, 9A3, 12A2-45, 11V9, 12S2-45SS, 12V5-45, for other types, please offer drawing, we can make customized design

Base Materials of Sintered Diamond and CBN Wheels

The base materials for sintered diamond wheels primarily include:

Aluminum Base: For aluminum-based metal bond wheels, the abrasive layer must be separately sintered and then bonded onto the aluminum base followed by precision machining. It’s important to note that aluminum bases cannot be placed in the sintering furnace with the abrasive layer, as the aluminum base could deform or even melt at high temperatures.

Steel Base: Steel-based metal bond wheels can be placed in the sintering furnace together with the abrasive mixture. This method ensures a more robust and integrated bond between the abrasive and the base, resulting in a cohesive structure.

Features

Key Components of Metal Bonding Agents

Metal bond agents are critically composed of multiple alloys. Key components include:

Copper/Tin Bronze (Cu/Sn)

Cobalt Bronze (Co/Cu)

Tungsten Carbide (W/WC)

Iron-Copper-Tin System Alloys (Fe/Cu/Sn)

Common copper/tin alloy ratios are generally 85:15 or 80:20, with additional fillers and alloying elements added to enhance performance. Particularly in diamond tools for stone drilling and cutting, metal bonding agent selection is paramount. Tools based on tungsten, tungsten carbide, or cobalt alloys offer high wear resistance and toughness, forming a favorable small-sized tungsten carbide interface layer with diamond particles, enhancing mechanical holding and chemical bonding strength.

Characteristics of Metal Bond Diamond and CBN Grinding Tools

Wear Resistance: High wear resistance suitable for prolonged, high-load grinding operations.

Strength: High strength abrasive bonding, ideal for heavy-duty grinding and rough grinding.

Thermal Conductivity: Excellent thermal conductivity efficiently dissipates heat generated during grinding.

Service Life: Due to high wear resistance and strength, metal bond wheels exhibit long service lives.

Applicability: Capable of grinding super-hard materials like diamonds and CBN, making them widely applicable.

High Grinding Precision: Maintain high precision and stability during grinding, suitable for high-precision grinding needs.

Advantages Over Other Bonding Types of Diamond and CBN Wheels

Durability: metal bond exhibit high strength and toughness, resisting impact and wear during grinding, extending wheel service life.

Thermal Conductivity: As a metal bonding agent, bronze effectively conducts heat away, preventing workpiece thermal deformation and burns.

Grinding Precision: Bronze sintered diamond/CBN wheels maintain high precision and stability during grinding, meeting high-precision requirements.

Dressing Bronze Sintered Diamond and CBN Wheels

Sintered diamond wheel dressing can be achieved through various methods:

Online Electrolytic Dressing:

Applied to precision metal bond diamond wheels, where the grinding wheel acts as the anode, and a cathode is mounted on the wheel end face. A soluble chemical grinding fluid is supplied to the gap between the wheel and the workpiece. When current passes between the electrodes, electrolytic action erodes excess metal, exposing the diamond abrasives for grinding.

EDM Dressing:

Utilizes heat energy or electrical sparks between the electrode and rotating metal bond diamond wheel to remove excess metal material from the wheel surface. This method achieves well-defined abrasive exposure heights, enhancing grinding performance.

For more comprehensive information and to explore our product range, visit Cast Grind Solutions. Let us help you achieve unmatched grinding performance.

Application

Applications of Sintered(metal bond) Diamond/CBN Wheels

Metal Bond Diamond Tools:

Primarily used for grinding high-hardness brittle non-metallic materials such as optical glass, ceramics, gemstones, and stone. These tools are widely used for infeed grinding, forming grinding on optical curve grinders, regrinding single-edged tools, grinding spiral grooves on small drills, and are suitable for electrolytic grinding.

Metal Bond CBN Tools:

CBN abrasives demonstrate unique advantages when grinding specific materials, making them indispensable in aerospace, automotive manufacturing, mold processing, and other industries. Compared to diamonds, CBN abrasives have higher thermal stability and chemical stability, especially suitable for grinding ferrous metals and high-hardness, tough metal materials. Metal bond CBN tools exhibit high hardness and strength, capable of enduring significant grinding pressures and impacts, making them ideal for high-efficiency batch grinding processes.

Metal Bond Diamond and CBN Tools Grinding Methods and Applications

- Surface Grinding

- Deep Cutting

- Glass Cutting

- Grooving

- Wet or Dry Grinding

- Cut Off

- Metal Working

Metal bond diamond and CBN grinding wheels can be utilized on wide range of material types. Such as:

- Optical Glass

- Tungsten Carbide

- Steel (Stainless, and heat resistant)

- Ceramic

- Quartz

- Titanium Alloy

- Automotive Parts Manufacturing such as engine crankshafts, camshafts, and gear shafts.

- Air Condition Parts Manufacturing.

- High-temperature alloy components such as aircraft engine blades and turbine discs.

- Various tools, molds, and gauges.

- Electronic components such as ceramic substrates and glass panels

Metal bond diamond and CBN wheels Shapes