In the metal processing industry, cold saws are gaining popularity as an efficient and eco-friendly cutting tool. However, the performance and longevity of cold saws depend not only on their design and materials but also on the choice and maintenance of grinding wheels. Cast Grind Solutions, a professional grinding wheel manufacturer, brings revolutionary changes to the metal processing industry with its high-efficiency, durable, and minimally-dressed cold saw grinding wheels.

1, Basic Knowledge of Cold Saws

1.1 What is a Cold Saw?

A cold saw is a high-precision cutting tool designed to transfer the heat generated during cutting to the chips, keeping the saw blade and workpiece cool. This is contrary to abrasive saws, which generate significant heat, affecting cutting quality and tool lifespan. The innovation of cold saws lies in their unique cooling mechanism, which enhances cutting efficiency and extends the lifespan of both the blade and workpiece.

1.2 Types of Cold Saws

Cold saws are primarily divided into High-Speed Steel (HSS) blades and Tungsten Carbide Tipped (TCT) blades.

High-Speed Steel (HSS) Saw Blades: Known for their high hardness and wear resistance, HSS saw blades are suitable for cutting various metals. Their cutting speed ranges between 10-150 meters per second, depending on the material and specifications of the workpiece. The tooth feed rate is between 0.03-0.15 mm/tooth.

Tungsten Carbide Tipped (TCT) Saw Blades: TCT blades feature tungsten carbide or cermet tips, providing higher hardness and wear resistance than HSS blades. Their cutting speed ranges from 60-380 meters per second, with a tooth feed rate of 0.04-0.08 mm/tooth, making them ideal for high-precision, high-efficiency cutting operations.

1.3 Can Cold Saws Be Reground?

Both types of cold saw blades—HSS and TCT—can be reground multiple times before being discarded. The re-grinding process requires the correct grinding wheels, such as diamond or CBN wheels, to maintain the blades’ efficiency and lifespan.

2 ,Advantages of Cast Grind Solutions Cold Saw Grinding Wheels

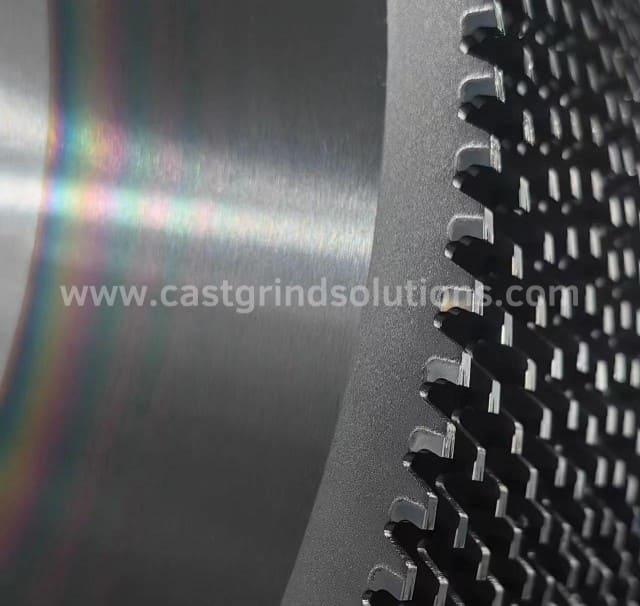

High-Efficiency Cutting: CGS saw blade chip break slot grinding wheels are made from advanced materials, ensuring the saw blades maintain high-efficiency cutting abilities after sharpening.

Strong Durability: The unique structure and material formula of Cast Grind Solutions’ saw blade grinding wheels ensure minimal wear during grinding, providing a high cost-performance ratio.

Minimal Dressing Requirements: Unlike traditional grinding wheels that need frequent dressing, Cast Grind Solutions’ grinding wheels maintain consistent cutting performance over extended periods, reducing the need for dressing and lowering production costs.

3, Applications of Cast Grind Solutions Cold Saw Grinding Wheels

Proper grinding and maintenance of cold saw blades are crucial for their performance and lifespan. For example, grinding TCT blades with Cast Grind Solutions’ diamond cold saw grinding wheels ensures high-efficiency grinding and a prolonged lifespan while maintaining the straightness of saw angles.

Case Study:

Equipment: Baibo Cold Saw Front Angle Grinding Machine

Saw Blade Specifications: 285X2.0X1.75X32X72T

Diamond Grinding Wheel Specifications: 125X32X3X2 D64 C100

Grinding Parameters: cold saw grinding Wheel speed at 3600 RPM, single-pass removal of 0.2mm, Linear traverse speed: 15 mm/min, diagonal traverse speed: 30 mm/min.

Dressing Interval: Every 140 saw blades, maintaining angle accuracy is paramount.

Through this example, it’s clear that selecting the right grinding wheel, parameters, and equipment is vital for maintaining saw blade cutting performance and extending their lifespan.

4, Future Outlook for Cast Grind Solutions Cold Saw Grinding Wheels

As the metal processing industry evolves, the demand for higher performance cutting tools increases. Cast Grind Solutions will continue to innovate, developing even more efficient, durable, and minimally-dressed grinding wheels to meet these demands. With the ongoing introduction of new grinding technologies and equipment, Cast Grind Solutions aims to provide comprehensive solutions for the metal processing industry.

In summary, Cast Grind Solutions‘ cold saw grinding wheels significantly revolutionize the metal processing industry with their high efficiency, durability, and minimal dressing features. Looking ahead, Cast Grind Solutions will remain at the forefront of industry development, supporting continued growth and innovation.