The Step Drill, also known as pagoda drill is a specialized type of drill designed for efficient hole-making processes, particularly excelling when working with thin sheet metal less than 3mm thick. This step drill bit innovative design allows a single drill to perform multiple diameter holes in one operation, eliminating the need for frequent tool changes or preliminary drilling steps, thus enhancing productivity.

Step drills can be customized with various cutting profiles (such as straight fluted, spiral fluted) and number of cutting edges (single, double, triple, quadruple, and multi-edged), catering to diverse material and application requirements. The drills are typically made from high-speed steel or tungsten carbide, ensuring both precision and durability.

For the production of pagoda drills, the use of CBN (Cubic Boron Nitride) grinding wheels has become a standard practice, demanding exceptional sharpness and shape retention qualities from these wheels. In response to this demand, our company has developed special hybrid diamond grinding wheels for carbide step drills production and hybrid CBN grinding wheels tailored for the production of hss step drills.

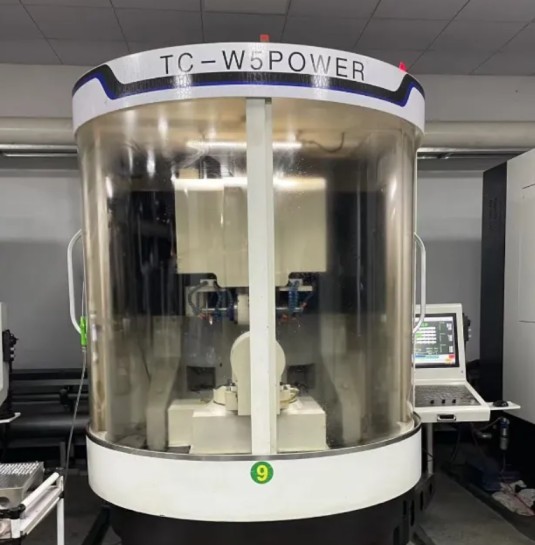

Below is a customer application showcase of CBN fluting grinding wheels utilized in the manufacturing process for high-speed pagoda drills:

Equipment:

Model: 5-axis cnc machine

Grinding Wheel:

Flute Grinding: 125×31.75×10×14×65°

External Grinding: 125×31.75×10×6.5,

Drill Point Grinding: 100×31.75×10×6,

Cooling: Oiling

Workpiece:

Material: Overall high-speed steel 4241

Maximum Diameter of Drill Bit: 36mm

Total Length of Step Drill: 58mm

Drill Spiral Angle: 60°

Number of Edges: 2

Grinding Process Parameters:

Grinding Wheel Speed: 25m/s

Maximum Depth of Cut for Flute: Approximately 6.5mm

Feed Rate: 70mm/min

Step Surface Grinding: 30 microns, with the first six steps at 250mm/min, the next four steps at 220mm/min, and the last two steps at 200mm/min;

End Face and Slot Grinding: 120mm/min

Sharpening Interval: Once every 10 drills

Total Processing Time: 9 minutes and 52 seconds

For inquiries related to drills that involve fluting or grinding, or for any similar procedures, kindly reach out to our engineer.