The performance and wear of brazed diamond grinding discs in machining gray cast iron can be influenced by several factors. Here are key considerations:

Diamond Grit Size:

The grit size of the diamond particles on the grinding disc affects the aggressiveness and surface finish. Coarser grits may offer higher material removal rates but can result in a rougher finish.

Brazing Quality:

The quality of the brazing process is crucial. A well-bonded diamond layer ensures stability during grinding. Inadequate brazing can lead to premature wear or detachment of diamond particles.

Material Hardness:

Gray cast iron has variable hardness depending on its composition and cooling rate during casting. Diamond discs must be selected based on the specific hardness of the cast iron to optimize performance.

Cooling and Lubrication:

Adequate cooling and lubrication during grinding are essential to prevent overheating and premature wear of the diamond disc. This is particularly important when dealing with heat-sensitive materials like cast iron.

Grinding Parameters:

The choice of grinding parameters, including speed, feed rate, and depth of cut, can impact the wear rate and overall performance of the brazed diamond disc. Optimal parameters should be determined through testing.

Surface Finish Requirements:

The required surface finish of the machined gray cast iron will influence the selection of the diamond disc. Finer grit sizes are often used for applications where a smooth surface is critical.

Tool Design:

The design of the brazed diamond disc, including the arrangement and concentration of diamond particles, plays a role in its performance. Well-designed discs ensure even wear and efficient cutting.

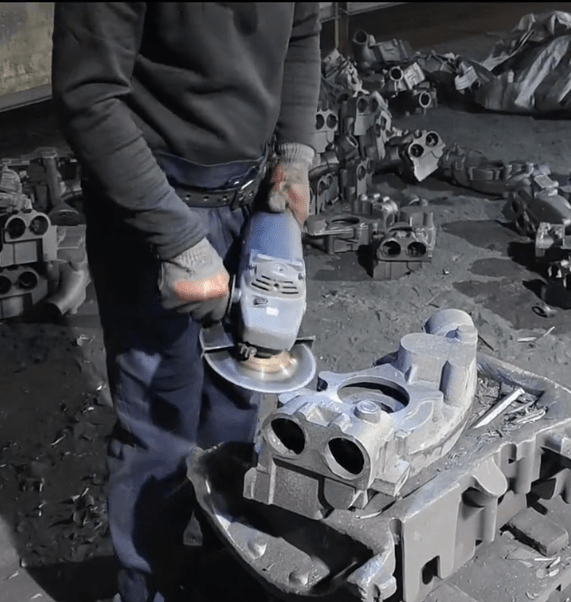

Operator Skill:

Operator expertise in setting up and using the grinding equipment can impact the overall performance. Proper handling and maintenance of the diamond disc contribute to its longevity.

Quality of Gray Cast Iron:

Variations in the quality and composition of gray cast iron can affect how it responds to grinding. The diamond disc must be suited to the specific characteristics of the material.

In our extensive testing, the CGS brazed diamond grinding disc consistently demonstrated significantly longer performance compared to standard resin bond grinding discs. The diamond disc exhibited an outstanding outperformance, surpassing the resin bond counterpart by an impressive factor of 80 to 100 times.