Diamond grinding discs are used for various applications across different industries. Here are some common uses:

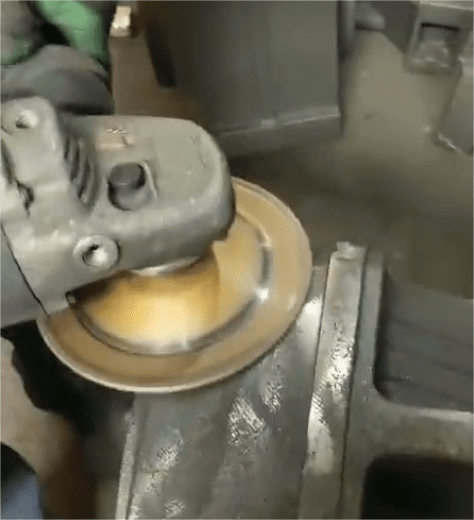

Metalworking:

Grinding and Sharpening: Diamond grinding discs are used for precision grinding and sharpening of metal components, including tools, blades, and hardened steel.

Construction and Masonry:

Concrete Grinding: Diamond discs are employed for grinding and smoothing concrete surfaces. They are used to remove irregularities, level the surface, and prepare it for finishing.

Stone Cutting and Grinding:

Granite and Marble: Diamond discs are crucial for cutting and grinding hard stones like granite and marble. They provide precision and efficiency in shaping and polishing these materials.

Glass Processing:

Glass Edging: Diamond grinding discs are used in glass manufacturing for edging and shaping glass pieces. They offer precise grinding without causing chipping.

Ceramic and Tile Industry:

Tile Cutting: Diamond discs are used for cutting and shaping ceramic tiles. They provide clean and accurate cuts, ensuring a smooth finish.

Woodworking:

Tool Sharpening: Diamond grinding discs can be used to sharpen woodworking tools such as chisels, plane irons, and router bits.

Metallography:

Material Analysis: In metallography, diamond grinding discs are used for preparing metallographic samples by grinding and polishing to analyze the microstructure.

Jewelry Manufacturing:

Gem Cutting: Diamond discs are employed for cutting and shaping precious stones and gems in jewelry manufacturing.

Automotive Industry:

Engine Component Grinding: Diamond grinding discs are used for precision grinding of engine components, providing a smooth finish.

These applications highlight the versatility of diamond grinding discs across various industries where precision, durability, and efficiency are crucial.