The grinder cutting process involves using a grinding machine to remove material from a workpiece through the action of an abrasive wheel. Here’s a breakdown of the grinder cutting process:

Preparation:

Ensure the workpiece is securely held in place, either manually or with the help of fixtures or clamps.

Selection of Grinding Wheel:

Choose an appropriate grinding wheel based on the material of the workpiece and the desired finish. Different wheels are designed for various applications and materials.

Setting Parameters:

Set the parameters on the grinding machine, including speed, feed rate, and depth of cut, depending on the specific requirements of the job.

Grinding Wheel Rotation:

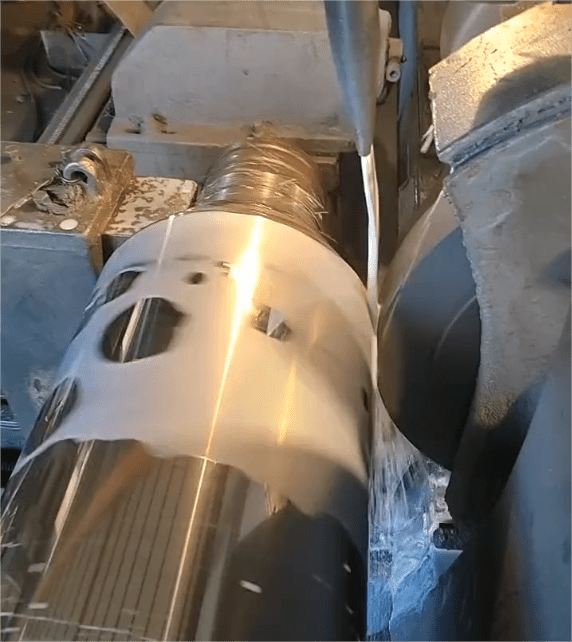

Start the grinding machine, causing the abrasive wheel to rotate. The rotation generates friction between the wheel and the workpiece.

Material Removal:

Bring the rotating grinding wheel into contact with the workpiece. The abrasive particles on the wheel cut into the material, removing excess material to achieve the desired shape or dimension.

Coolant Usage:

Depending on the application, coolant may be applied to the workpiece during grinding to control heat generation and prevent damage to the workpiece or the grinding wheel.

Controlled Movement:

Move the grinding wheel across the surface of the workpiece in a controlled manner. This movement, combined with the rotating wheel, results in material removal and shaping.

Precision Grinding:

For precision grinding, the process is carefully controlled to achieve tight tolerances and the required surface finish. This is often crucial in applications where accuracy and smooth surfaces are essential.

Monitoring and Adjustments:

Continuously monitor the grinding process and make adjustments as needed to ensure consistent material removal, prevent overheating, and achieve the desired outcome.

Final Inspection:

After the grinding process is complete, inspect the workpiece to ensure it meets the specified dimensions, surface finish, and other quality requirements.

Grinder cutting is versatile and widely used in various industries for shaping, finishing, and refining workpieces made of metals, ceramics, composites, and other materials. The specific parameters and techniques employed in the grinder cutting process can vary based on the material being processed and the desired results.